Paper Honeycomb and Tube Pallet

a tube pallet and honeycomb technology, applied in the field of paper honeycomb and tube pallets, can solve the problems of high environmental concern, high cost of wood pallets, and high cost of wood pallets, and achieve the effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the description that follows, like elements are marked throughout the specification and drawings with the same reference character, respectively. The drawing figures are not necessarily to scale. Further, description of the assembly and various elements, components or portions of the assembly are provided according to their orientation as depicted in the drawings and are not meant to be limiting in any way.

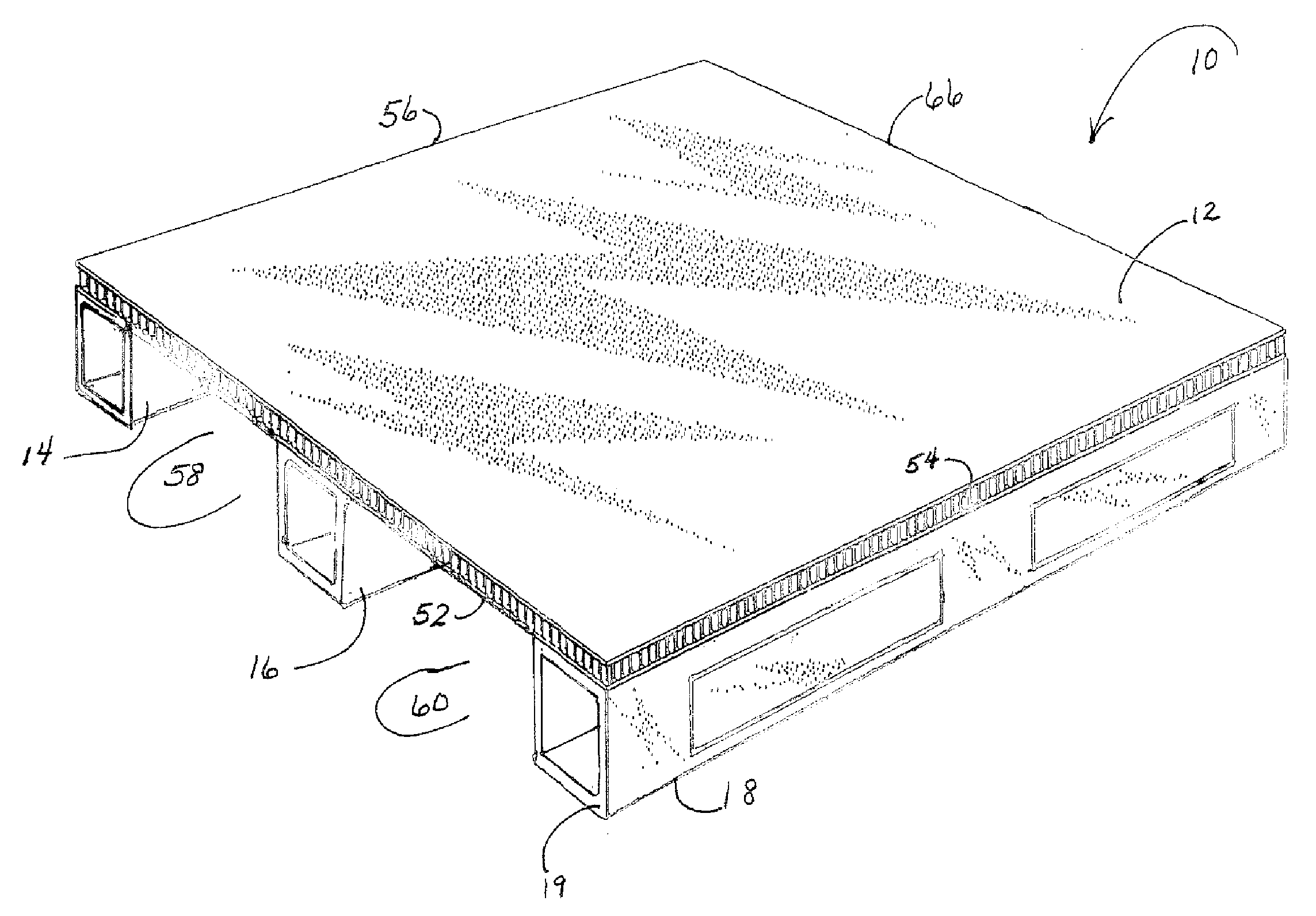

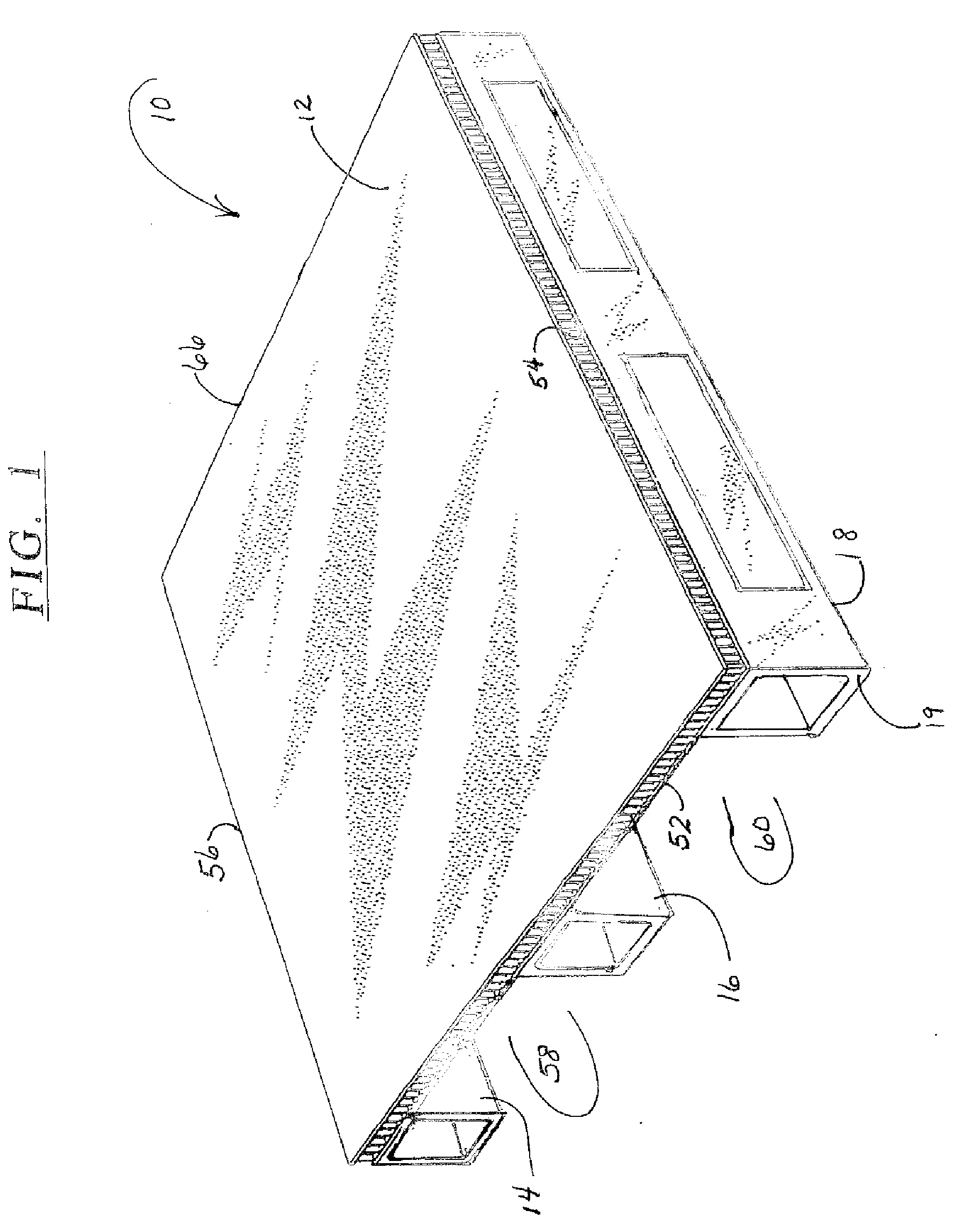

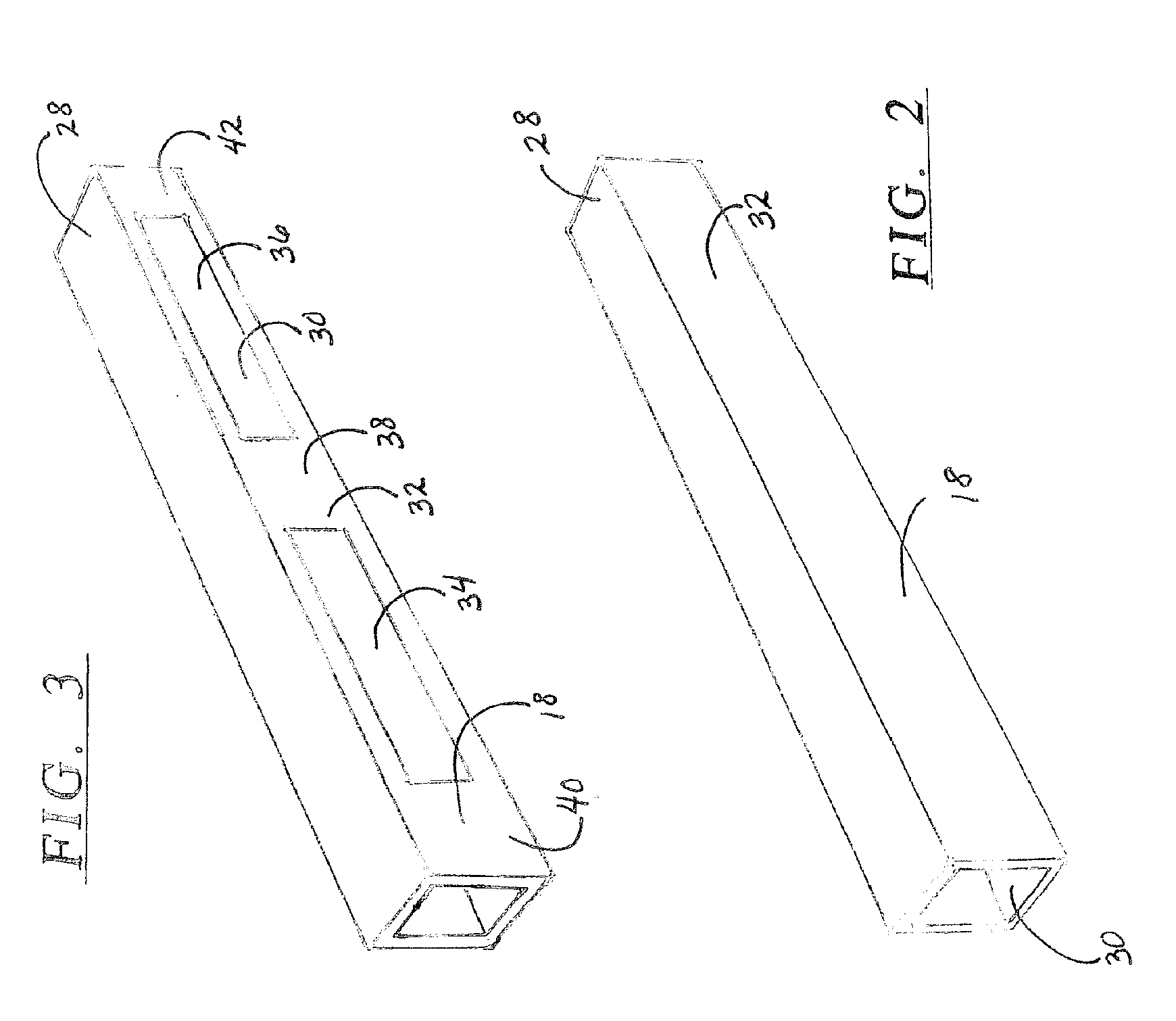

[0028] With reference to FIG. 1, the preferred embodiment, generally 10, has a rectangular pallet base 12 mounted on three support runners or beams 14, 16, 18. The thickness of the base 12 varies depending on the load to be carried by the pallet 10. The support runners, e.g., 18, are each made with numerous sheets of paper, or chipboard, or corrugated wrapped layer upon layer and individually glued together with polyvinyl acetate or similar glue or a moisture resistant glue. The paper, or chipboard, or cardboard may be treated with moisture resistant chemicals or a mois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com