Cylindrical microphone having an electret assembly in the end cover

a technology of electret assembly and cylindrical microphone, which is applied in the direction of transducer types, microphone structural associations, electrical apparatus, etc., can solve the problems of reducing the size, requiring a larger volume of the transducer, and reducing the volume at the expense of performance or manufacturability, and achieves the effect of being insensitive to vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

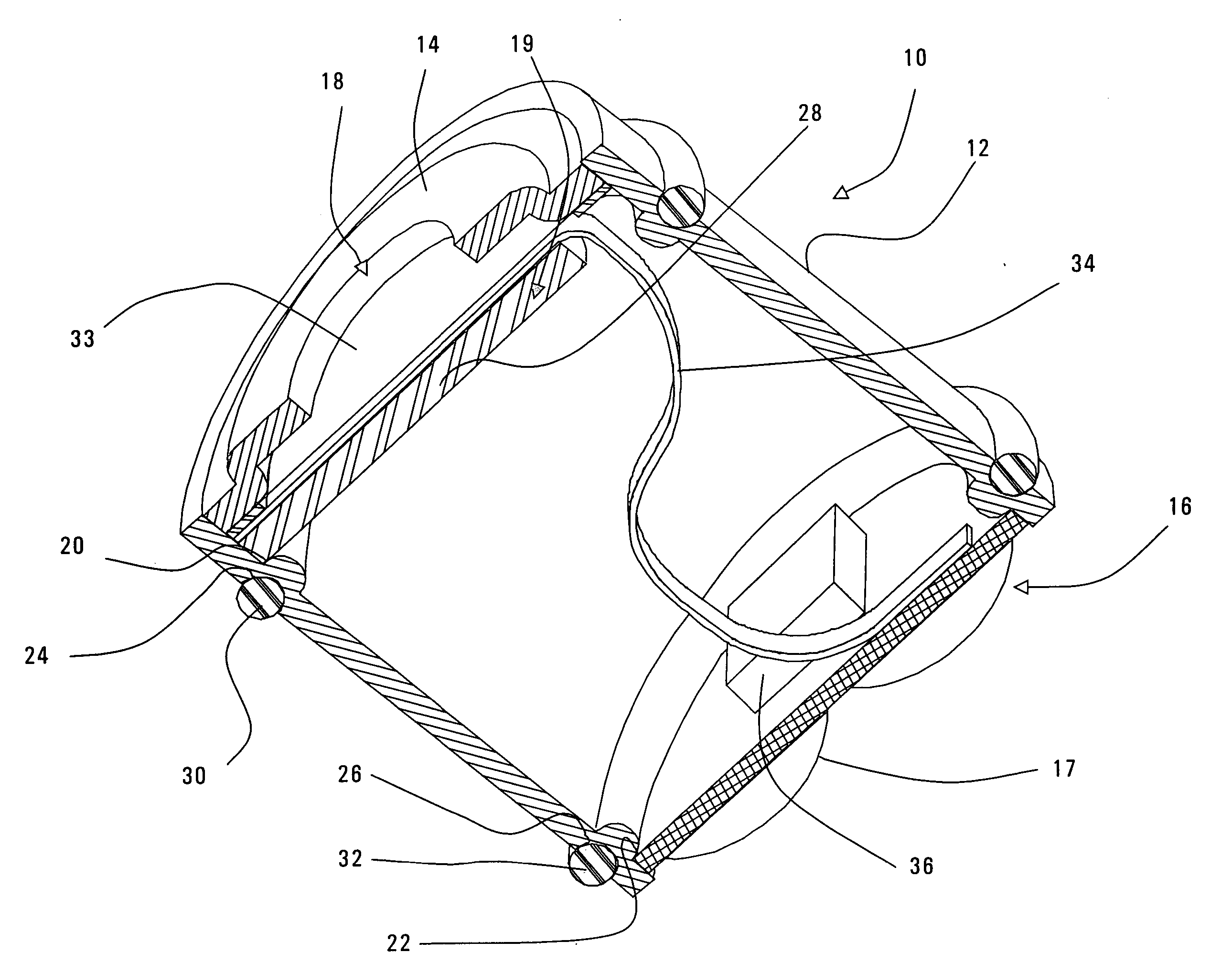

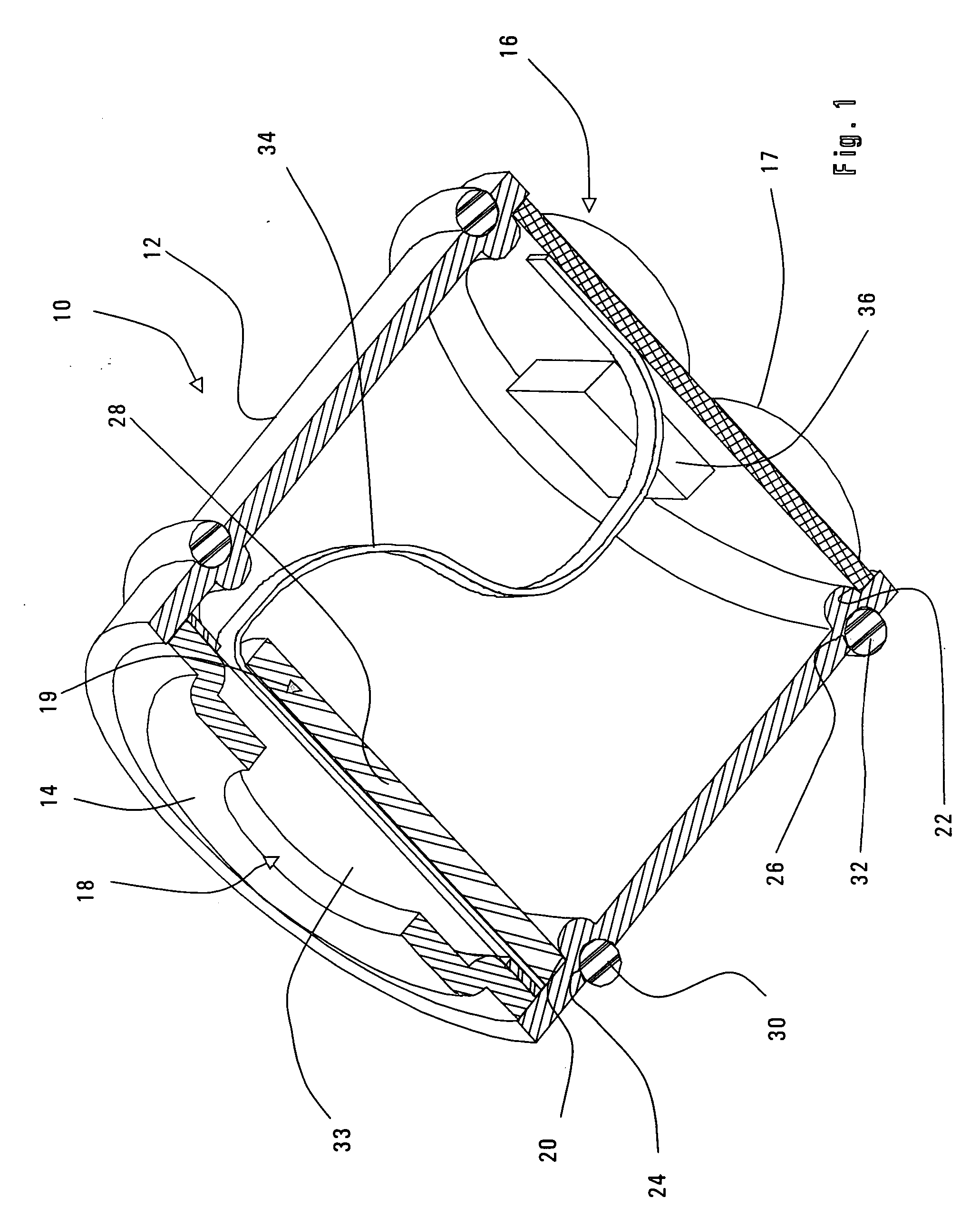

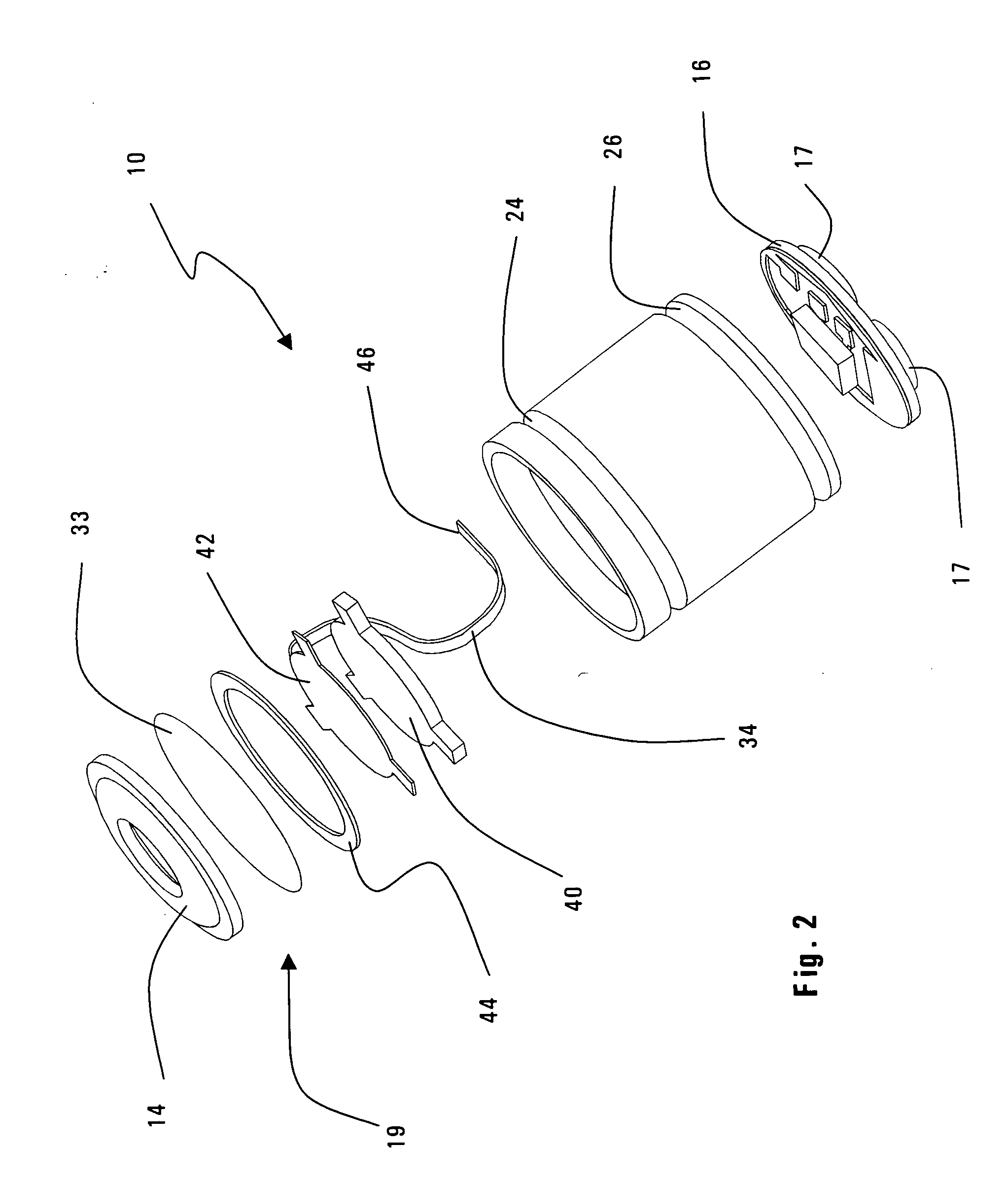

[0023] Referring to FIG. 1, a microphone 10 according to the present invention includes a housing 12 having a cover assembly 14 at its upper end and a printed circuit board (PCB) 16 at its lower end. While the housing 12 has a cylindrical shape, it can also be a polygonal shape, such as one that approximates a cylinder. In one preferred embodiment, the axial length of the microphone 10 is about 2.5 mm, although the length may vary depending on the output response required from the microphone 10.

[0024] The PCB 16 includes three terminals 17 (see FIG. 2) that provide a ground, an input power supply, and an output for the processed electrical signal corresponding to a sound that is transduced by the microphone 10. The sound enters the sound port 18 of the cover assembly 14 and encounters an electret assembly 19 located a short distance below the sound port 18. It is the electret assembly 19 that transduces the sound into the electrical signal.

[0025] The microphone 10 includes an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com