Winged hull for a watercraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

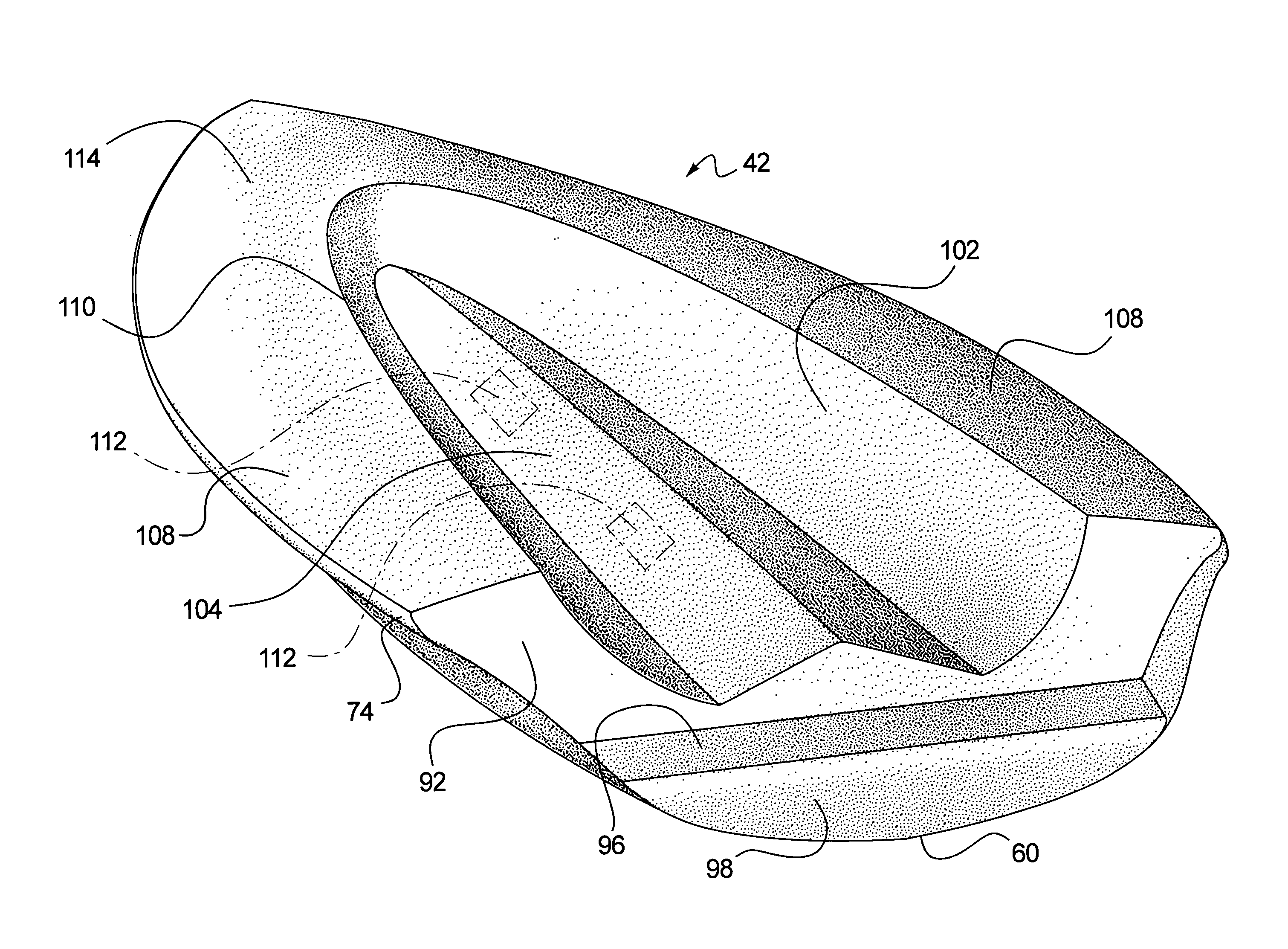

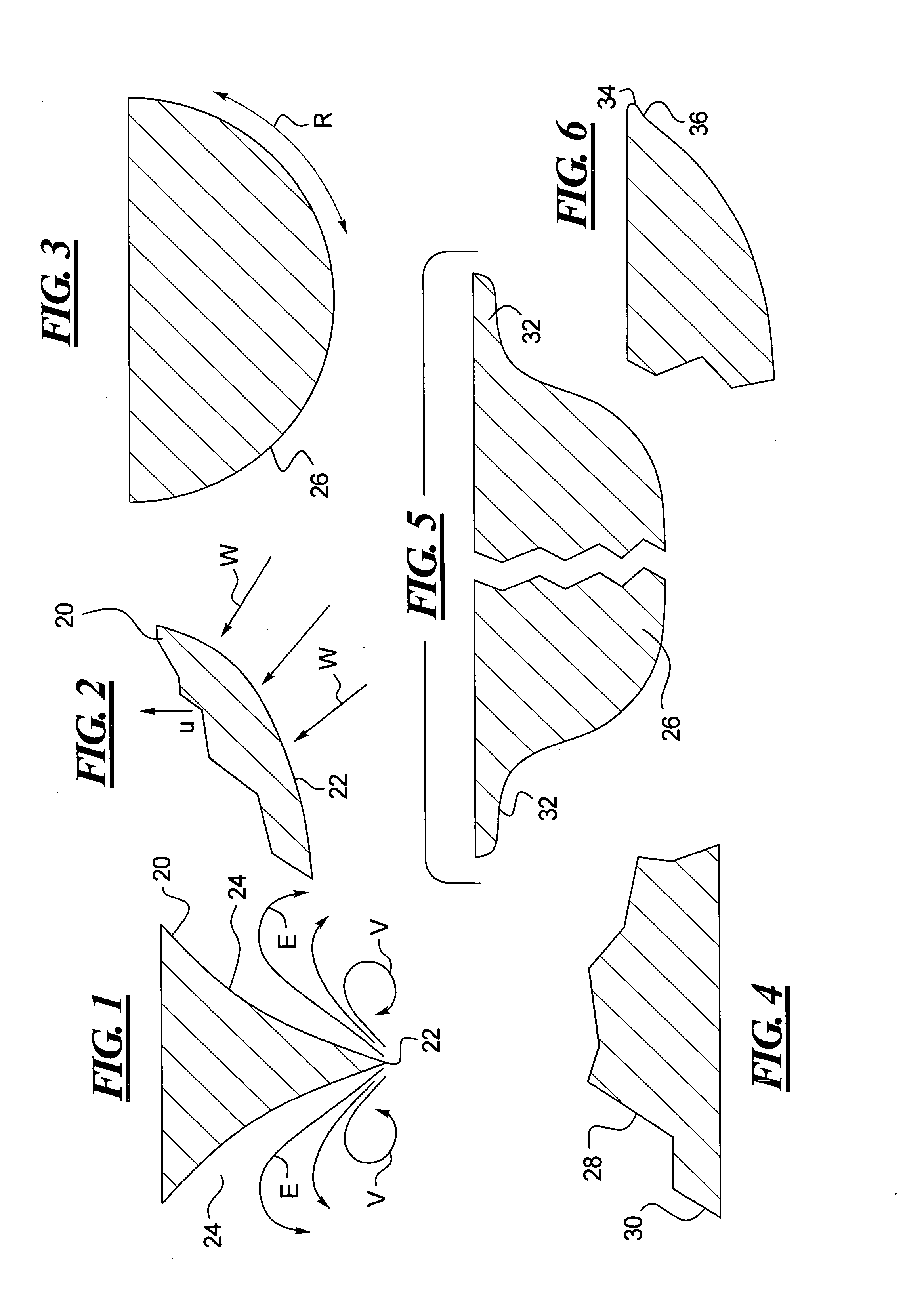

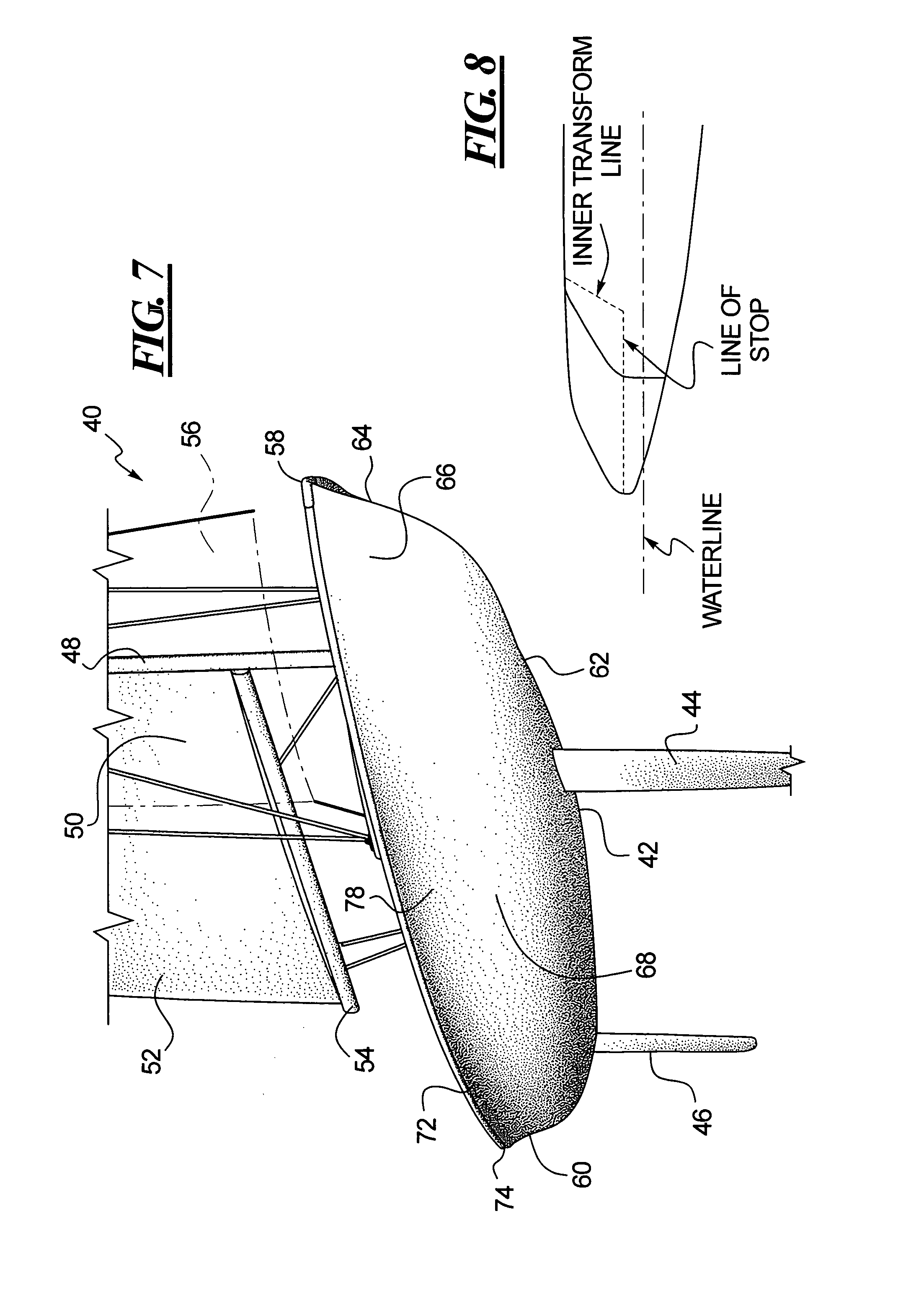

[0055] The sailboat hull of the present invention utilizes hydrodynamic shaping to provide a performance sailboat hull that moves quickly and efficiently through the water. A preferred embodiment of a more optimized hull is demonstrated in an 18 foot sailboat. A front portion of the hull has a shape to ease water entry and to shape the water flow at the front of the boat. FIG. 1 shows a schematic representation of the water entry portion of the present hull in transverse cross section (also see FIG. 14 that shows the present embodiment prototype sailboat from the bow view). FIG. 2 shows this same water entry portion of the hull in the longitudinal starboard side view. In particular, the water entry includes a relatively sharp edge 22 that slices into the water.

[0056] The sharp edge 22 is followed by a pair of outwardly angled concave surfaces 24. These outwardly angled concave surfaces 24 receive and direct the water that is sliced by the edge of the bow and direct it not only up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com