Method and Device for Producing a System Having a Component Applied to a Predetermined Location of a Surface of a Substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

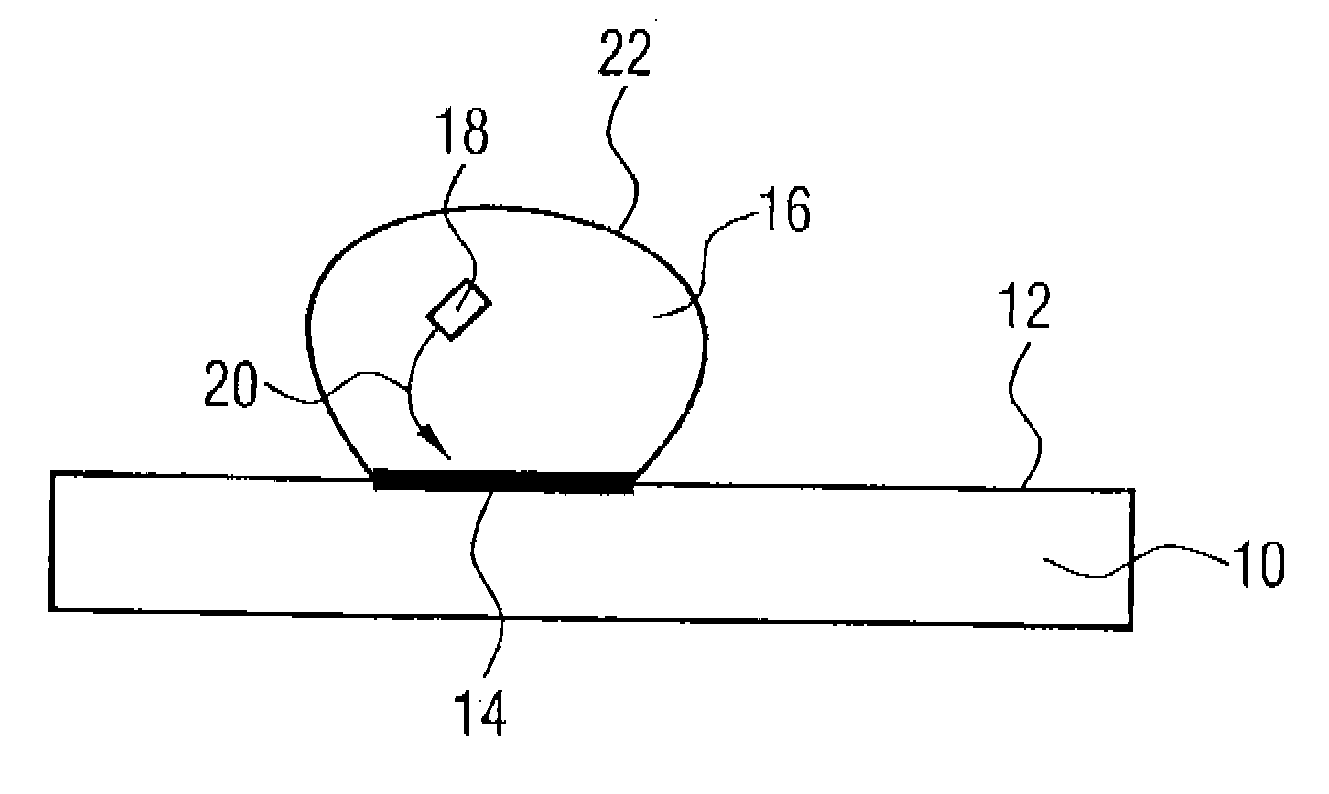

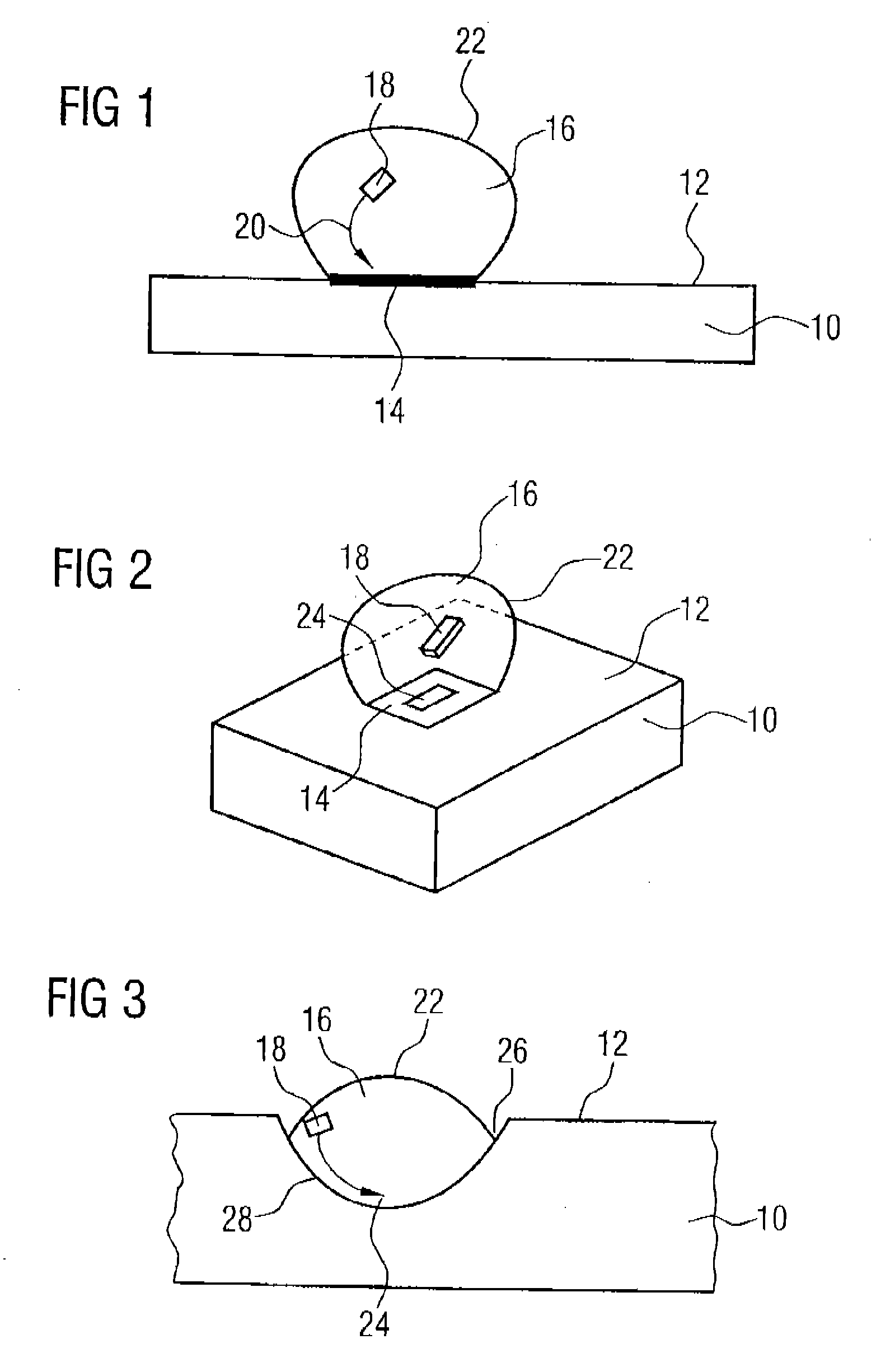

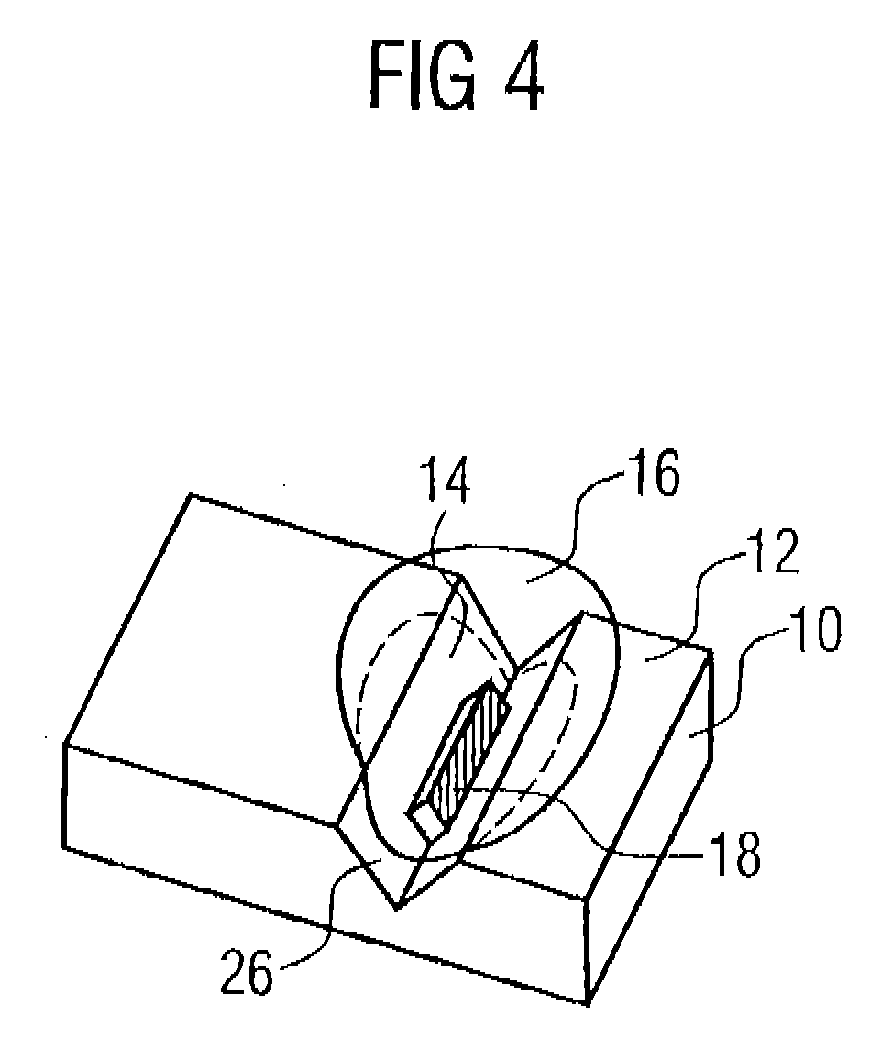

[0023]FIG. 1 is a schematical illustration of a substrate 10 with a surface 12 according to a first embodiment of the present invention. A partial area 14 of the surface 12 is wetted by a liquid volume 16 containing a component 18. The substrate 10 is for example a printed circuit board, a ceramic substrate, paper or foil, a semiconductor substrate or another substrate, to which or to whose surface 12, respectively, the component 18 is to be applied. The component 18 is for example an electronic, microelectronic or micromechanical device which in turn for example consists of a semiconductor material or of plastics. The component 18 was for example formed together with many other like components in a device substrate and was then separated. The component 18 preferably comprises dimensions in a range from 1 nm to one or few mm.

[0024] The liquid volume 16 containing the component here is a drop which was for example applied to the surface 12 of the substrate 10 by an inkjet printing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com