Roll of paperband

a paper band and roll technology, applied in the field of paper band roll, can solve the problems that none of the above-described paper devices is satisfactory for use in the paper band track assembly beneath the wide paper machine, and achieve the effect of shortening the length of the paper band and minimizing the tearing of the paper band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

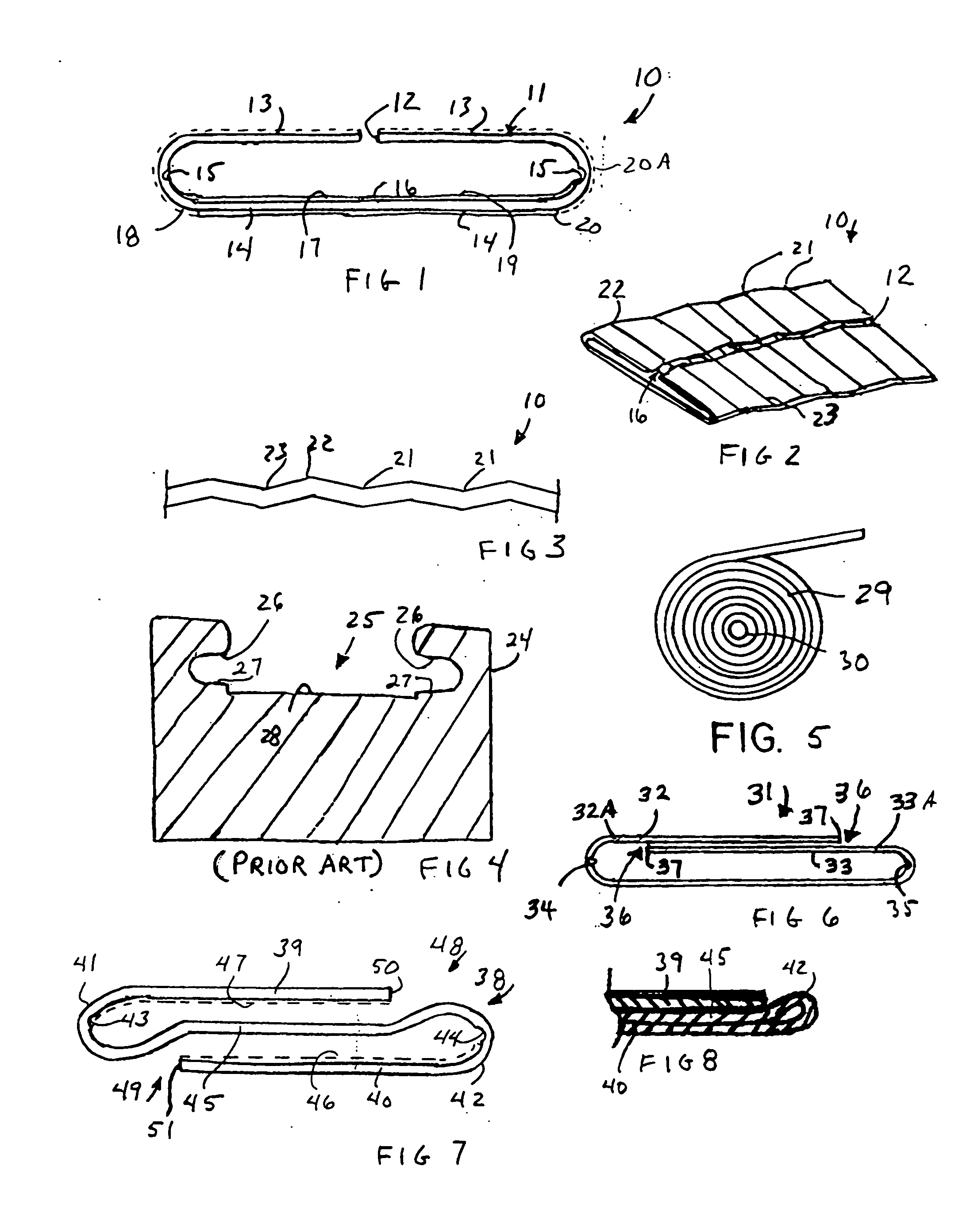

second embodiment

[0034]FIG. 6 illustrates the paperband 31 having partially overlapping side portions 32, 33 defined by longitudinal score lines 34, 35 and edges 37. The section of the paperband 31 between the side portions 32A, 33A do not overlap, form longitudinal lines or narrow areas of weakness 36 since the edge portions are two layers of the multi-ply material which the center portion has three layers of the material and permit bending along 36 of the paperband 31 during turn-up or other uses.

third embodiment

[0035] In FIG. 7, a paperband 38 includes side portions 39 and 40 and a medial or center portion 45 folded to form a generally S-shape. The side portion 39 is folded about longitudinal score line 43 forming a “soft bend”41. The other side portion 40 is similarly folded about longitudinal score line 44 to form a “soft bend”42. Areas of weakness or flexible joints 48 and 49 are created during the transition from three layers to two layers. Adhesive layers 46 and 47 are shown on opposed surfaces of the paperband 38, i.e., an upper surface of side portion 39 and a lower surface of side portion 40. Alternately, the adhesive 46, 47 may be applied simultaneously to both surfaces of center portion 45. This method may be accomplished by feeding the unfolded paperband board vertically to permit the adhesive 46, 47 to be sprayed on or otherwise applied to center portion 45 by any appropriate technology.

[0036] The performance of paperband 38 is similar to that of paperbands 10, 31 in track pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

| stretchability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com