Axial flow fan improvements

a technology of axial flow fans and fans, which is applied in the direction of lighting and heating apparatus, ventilation systems, heating types, etc., can solve the problems of imposing severe demands on fans, affecting production, and indoor conditions becoming much hotter than before, and achieves the effect of quiet operation and effectively overcoming prior art drawbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0086] With reference to FIGS. 9A, 9B, 9C, 10, and FIG. 11, the present invention is shown and described.

[0087] The axial flow fan 10″ of the present invention is similar to the fan 10 herein above described and comprises similar components as the fan 10 of the first embodiment of the invention set above. However, the housing 11″ is more compact than housing 11, a centrifugal mechanism 33″ (similar to the 33) is rotatably connected to the shutter assembly 39″ which comprises a pair of vertically pivoting doors 41″ and 42″ opened and closed by said centrifugal mechanism 33″ that is mounted to one end of a fan hollow shaft 21″ opposite to the propeller 20A and comprises an axial sliding reciprocating actuator member 56″ mounted on a hollow guide 54″. The reciprocating actuator member 56″ comprises a compression operative biasing means 64″ and an operative rod 201 adapted to pass through the fan hollow shaft 21″. The operative rod 201 is threaded and fastened with nut 202 to one end to...

fourth embodiment

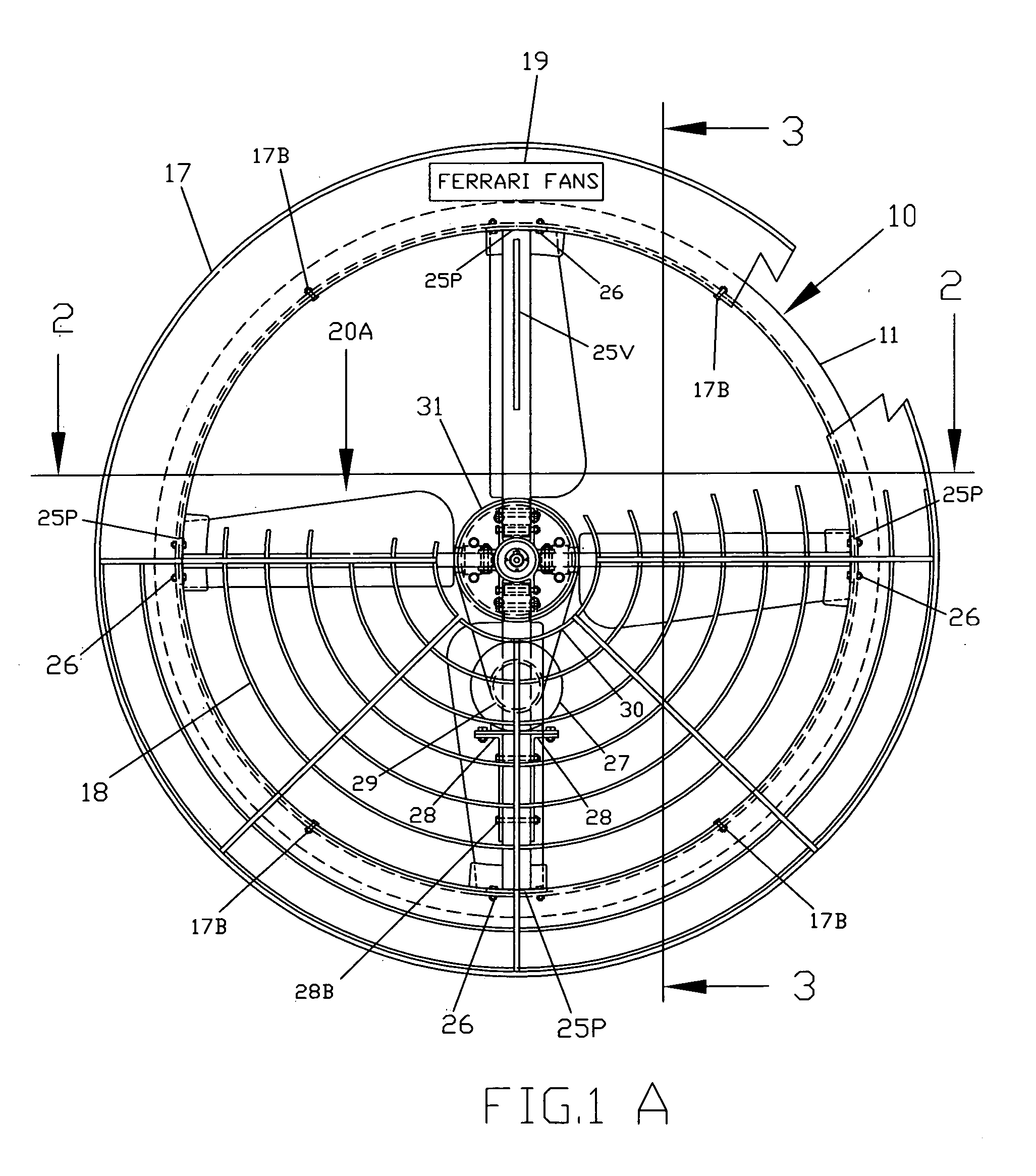

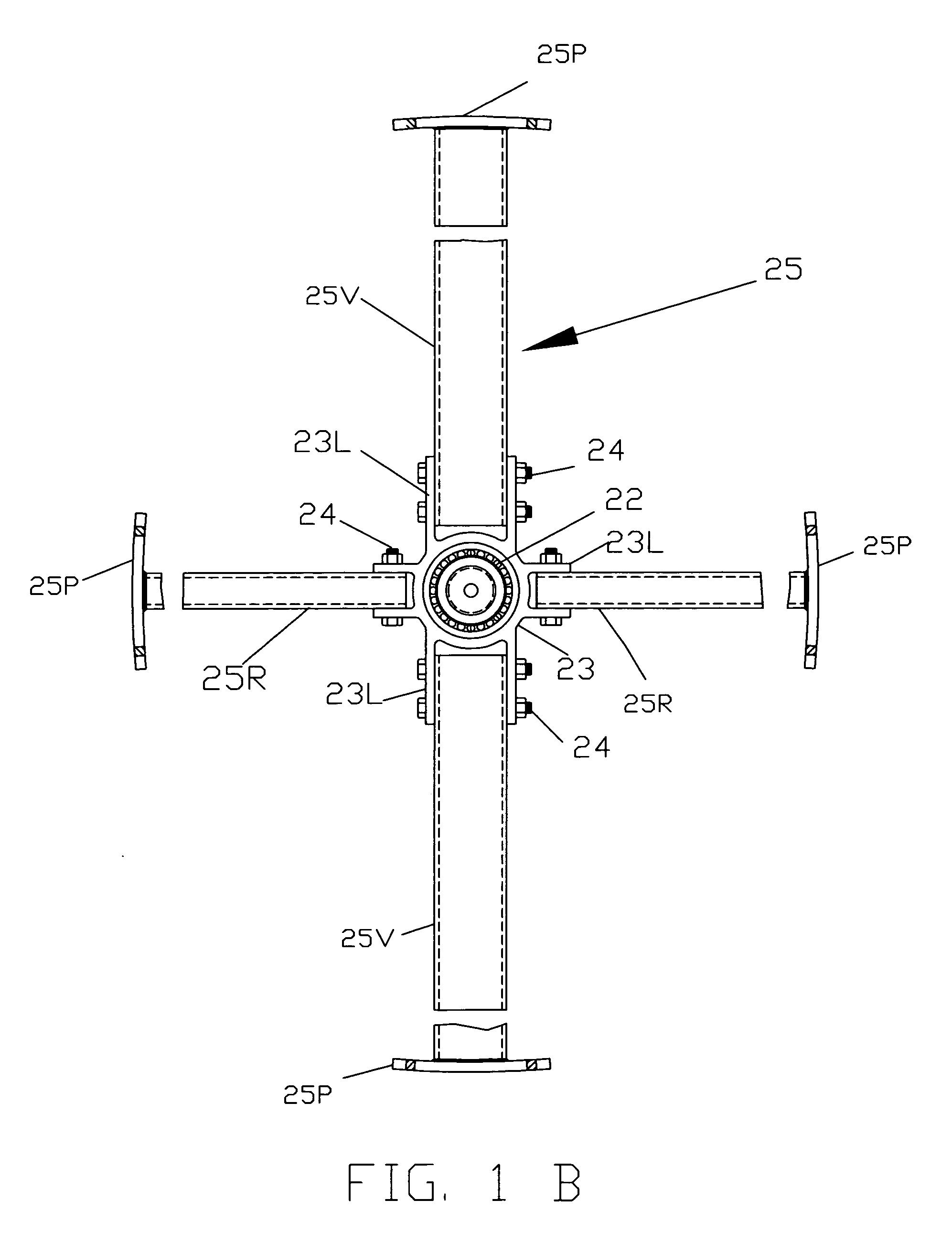

[0094] With reference now to FIGS. 17A, 17B, FIG. 18 and FIG. 19 the present invention is illustrated and described. The axial flow fan 400 of the present invention comprises a cylindrical shaped housing 411 comprising an air intake end 412 and an air output end 413. The fan housing 411 is preferably made of one-piece of rolled steel or aluminium sheet metal. The air intake end 412 is provided with a bell shaped mouth 17 secured with mechanical fasteners 17B thereto and is provided with a bracket 25″ (similar to the bracket 25 of FIG. 1B) secured with mechanical fasteners 25B″ to four opposite sides of said air intake end for supporting a propeller 20A best shown in FIGS. 4, 5 and 6).

[0095] A shutter assembly 439 is mounted at the fan discharge end 413 and comprises a plurality of even angularly spaced pair of vanes 414 comprising leading edges connected to each other with a hinge 414H comprising four intersecting rods including a horizontal stationary rod 209″R and a stationary ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com