Cooling System

a cooling system and cooling fluid technology, applied in the field of cooling systems, can solve the problems of large energy consumption compared with the conventional direct expansion type cooling system, and achieve the effect of running cost saving and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

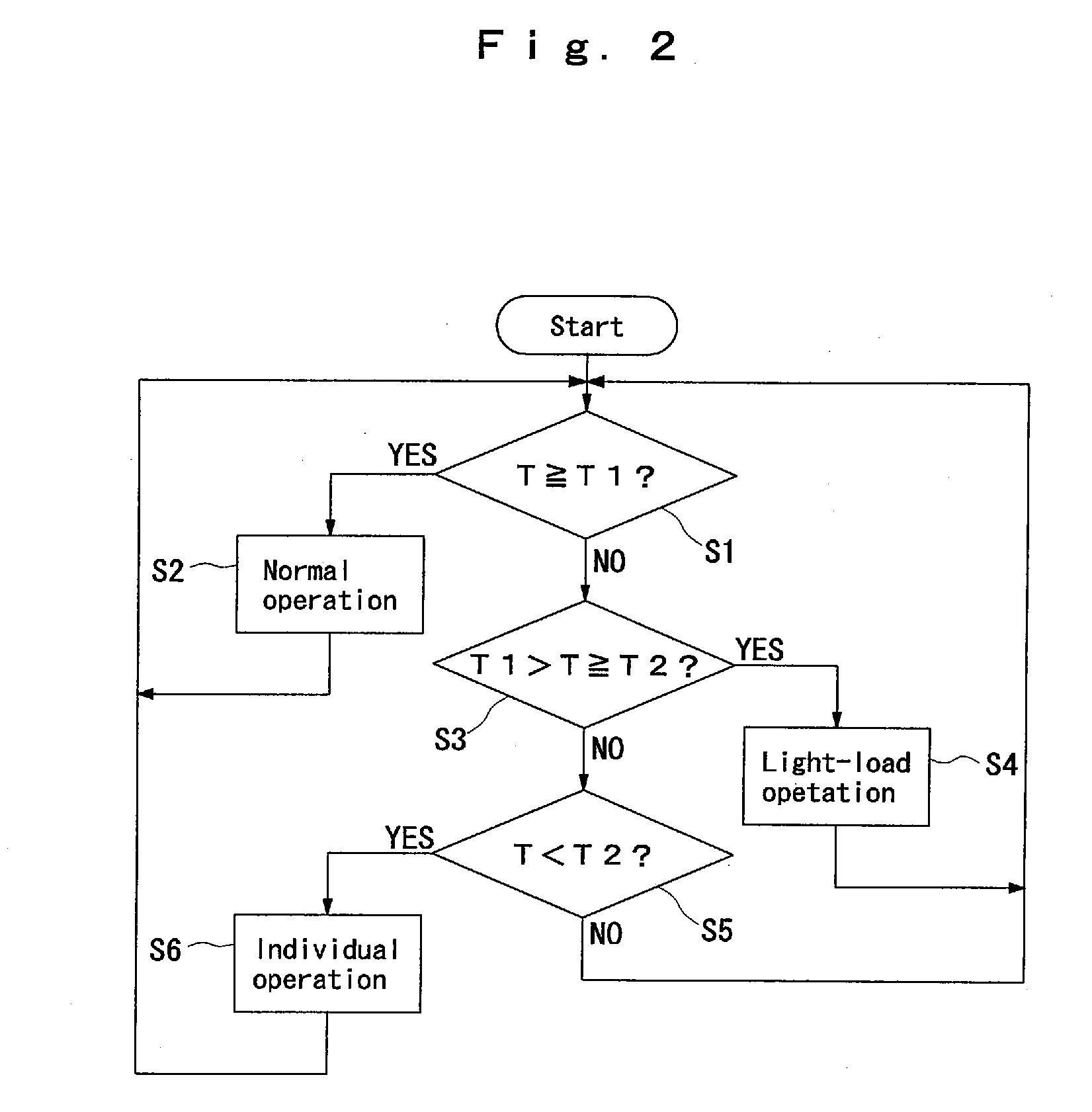

[0019]FIG. 1 to FIG. 5 shows a preferred embodiment of the invention.

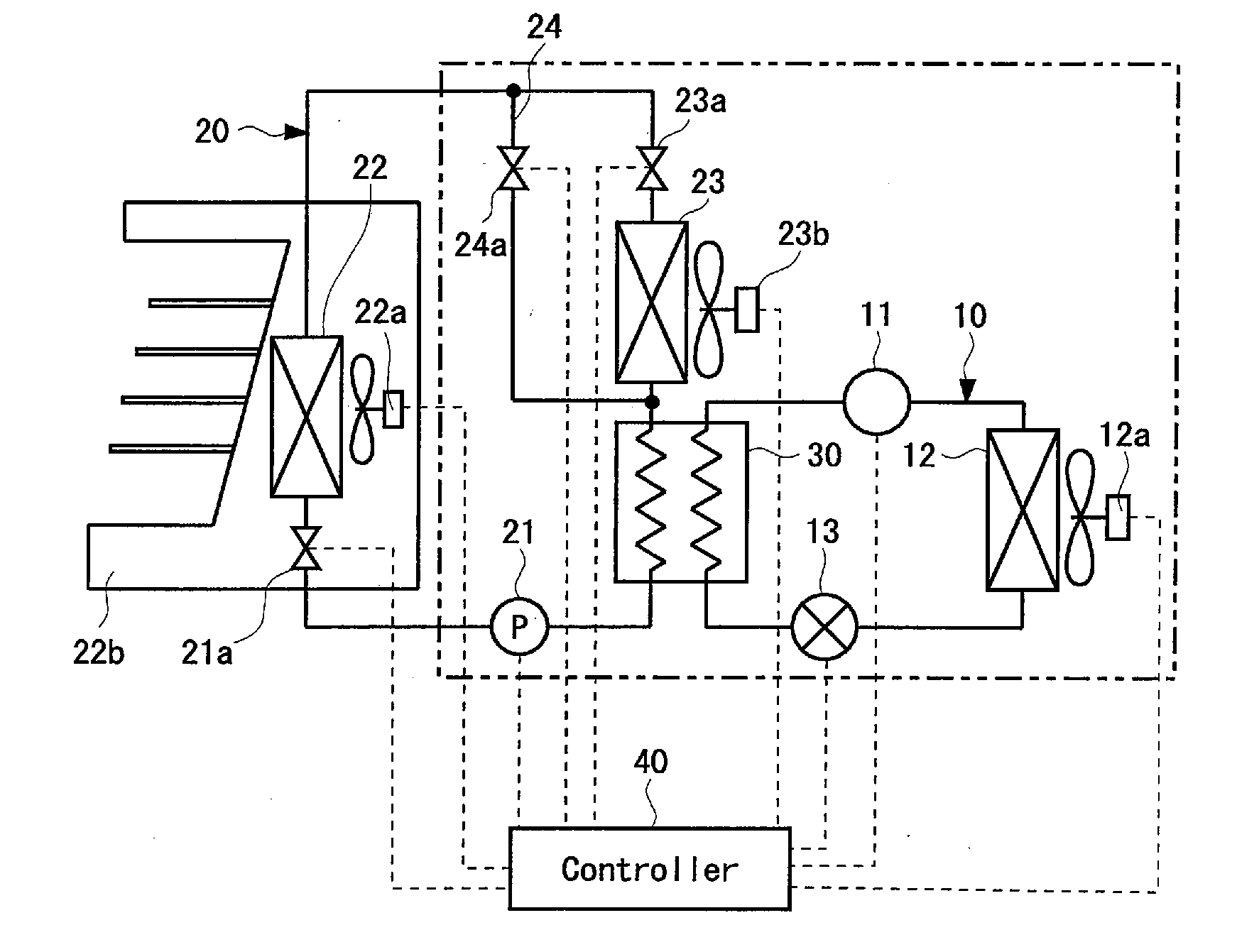

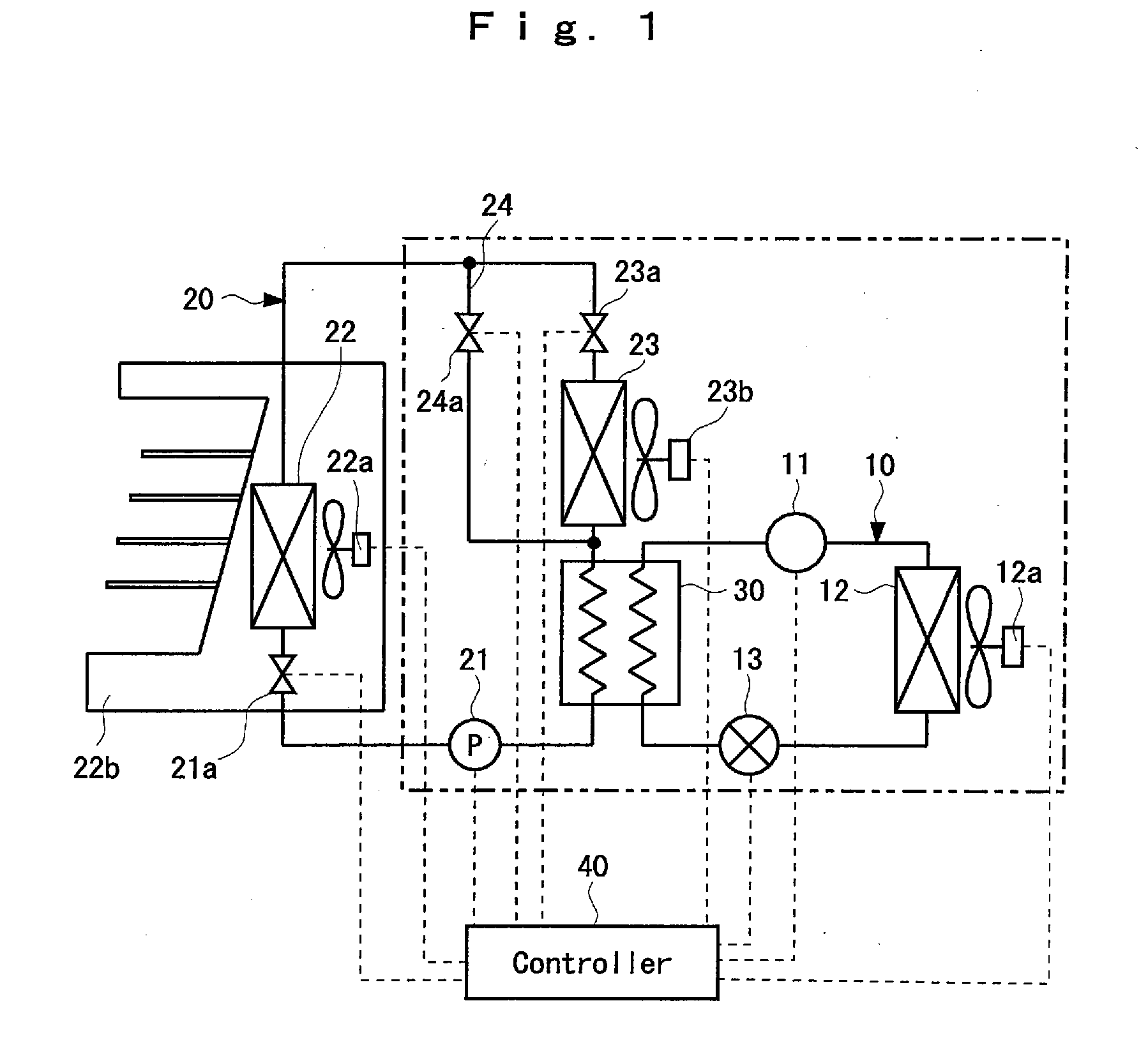

[0020] A structure of a cooling system using brine will be explained with reference to FIG. 1 and FIG. 2. The cooling system has a refrigerant circuit 10, a brine circuit 20, and a first heat exchanger 30.

[0021] The refrigerant circuit 10 has a compressor 11, a condenser 12, and an expansion valve 13. A refrigerant circulates to the compressor 11, the condenser 12, the expansion valve 13, the first heat exchanger 30, and the compressor 11 in this order. The condenser 12 has a first blower 12a. The first blower 12a forcibly brings the outdoor air into contact with the condenser 12. The refrigerant used in the refrigerant circuit 10 is Freon, non-Freon (e.g., ammonium), or the like.

[0022] The brine circuit 20 has a pump 21, a cooler 22, and a second heat exchanger 23 for performing heat exchange between the brine and the outdoor air. In the brine circuit 20, the brine circulates to the pump 21, the cooler 22, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com