Composite briquettes for electric furnace charge, and in their method of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

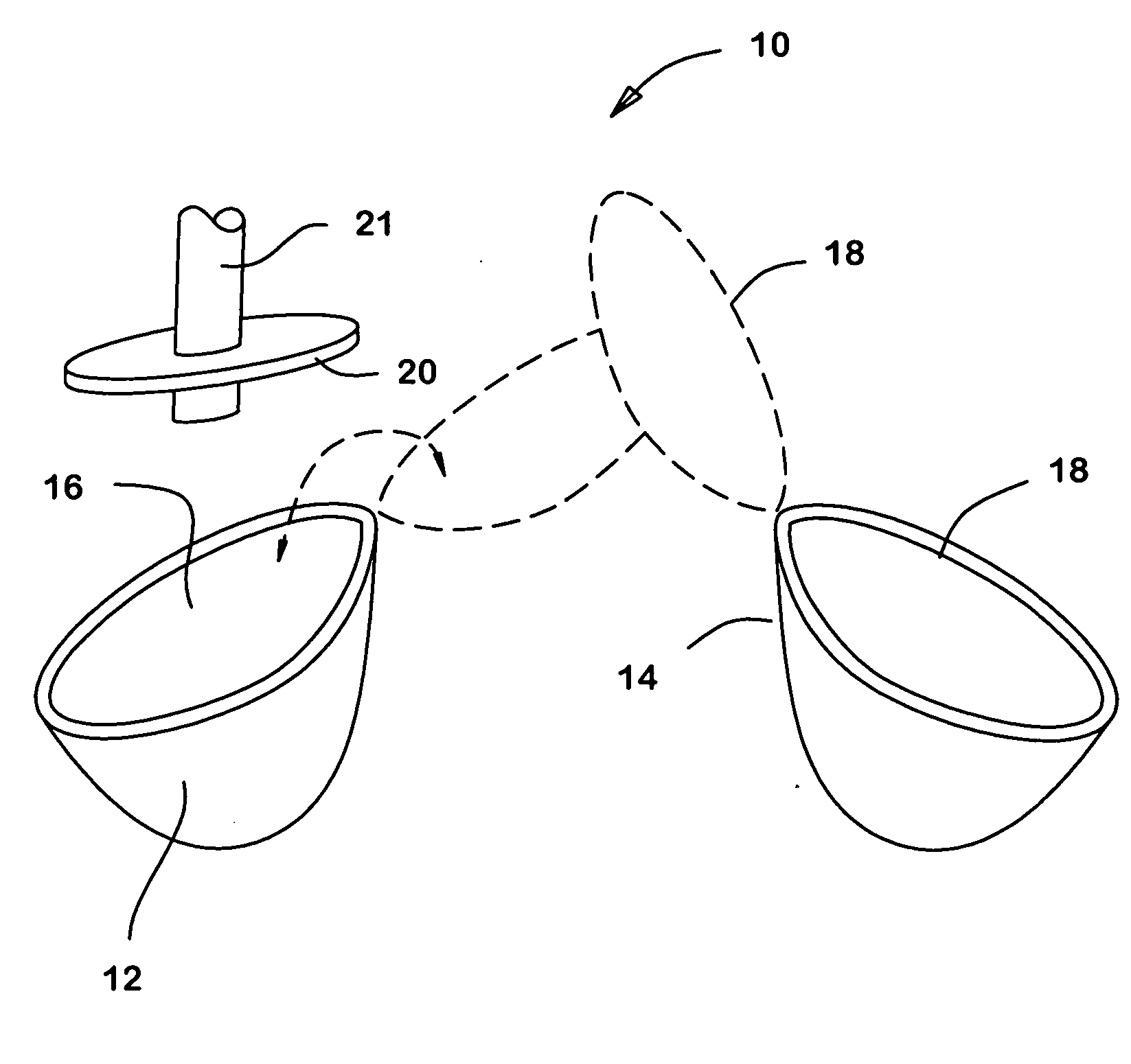

[0055] A dual shell electric furnace 10 has the following basic components: [0056] 1. a first furnace shell 12 shaped essentially as an open-topped container adapted to hold a steel melt; [0057] 2. a second furnace shell 14 substantially similar to the shell 12; [0058] 3. a cover 16 swingable between an open position (that shown in FIG. 1) and a closed position in which it substantially closes the open top of the first shell 12; [0059] 4. a cover 18 swingable between an open position (that shown in FIG. 1) and a closed position in which it substantially closes the open top of the second shell 14; [0060] 5. an electrode cover 20 which can close either of the shells selectively, the electrode cover being movable between the shells, and also being capable of assuming an out-of-the-way location. The electrode cover 20 is illustrated as having three electrodes 21 passing through the cover, although the number of electrodes is not critical. When the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com