Pneumatically actuated disk brake with electromotive adjusting devices and method for controlling the disk brake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

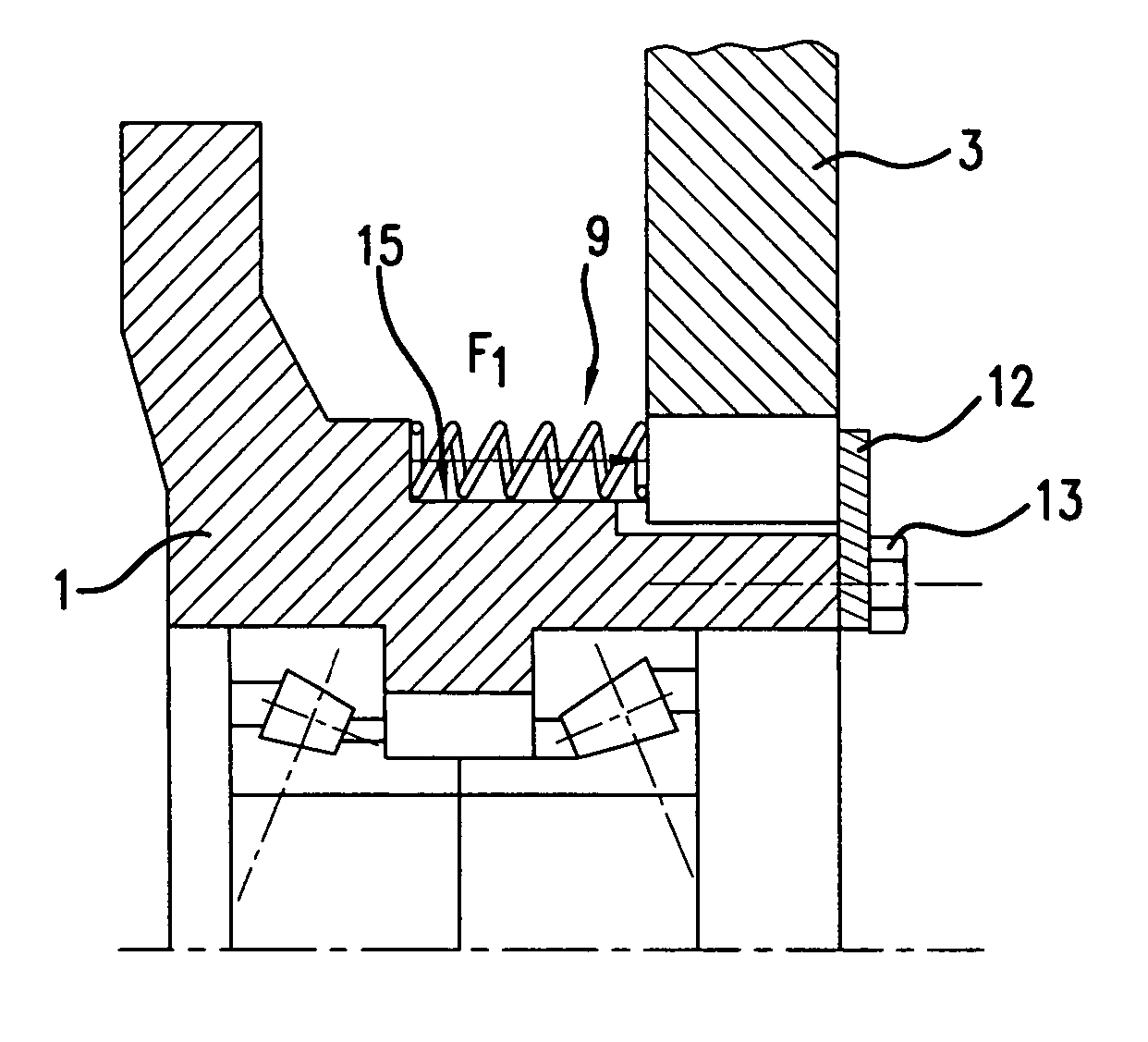

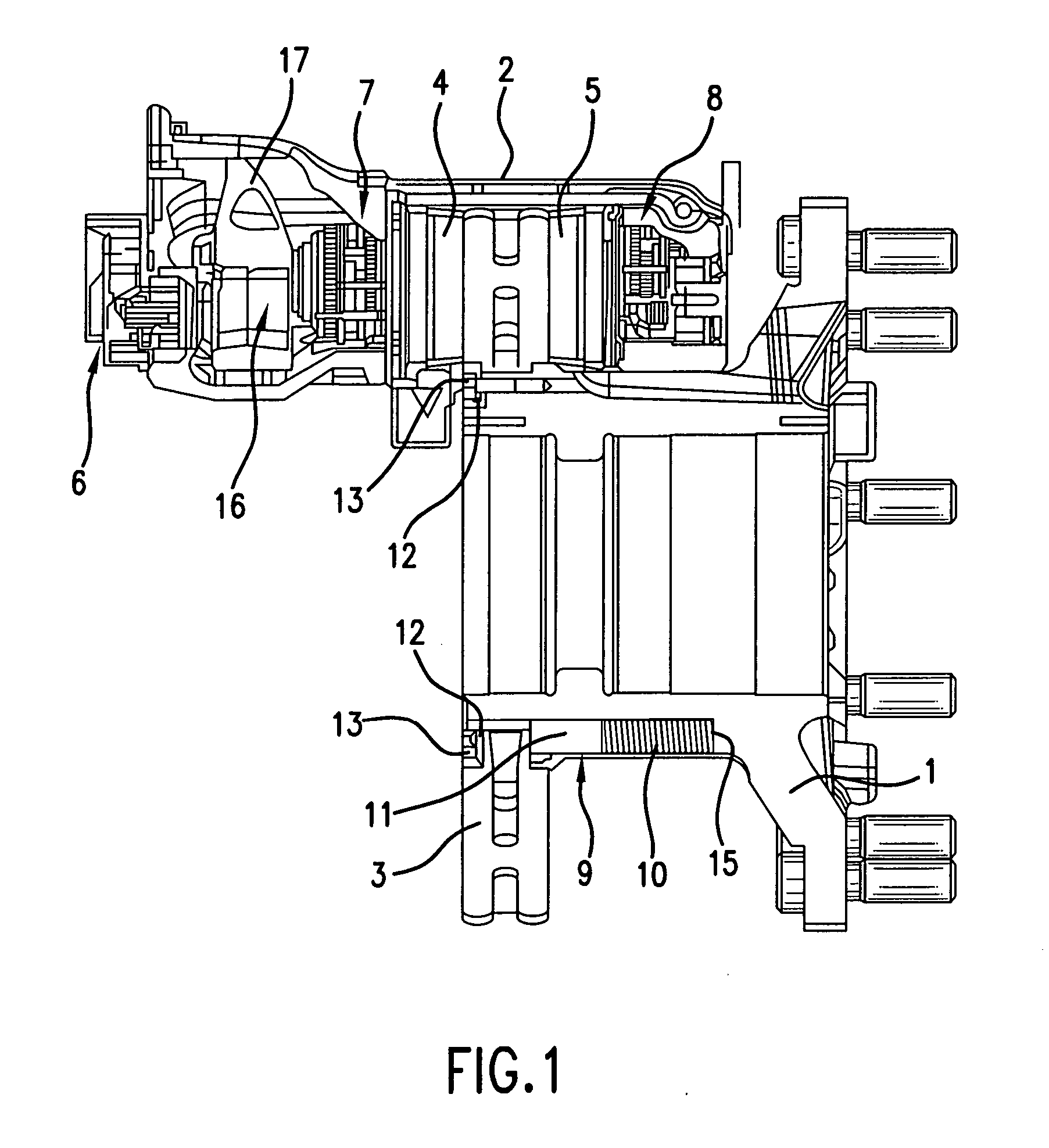

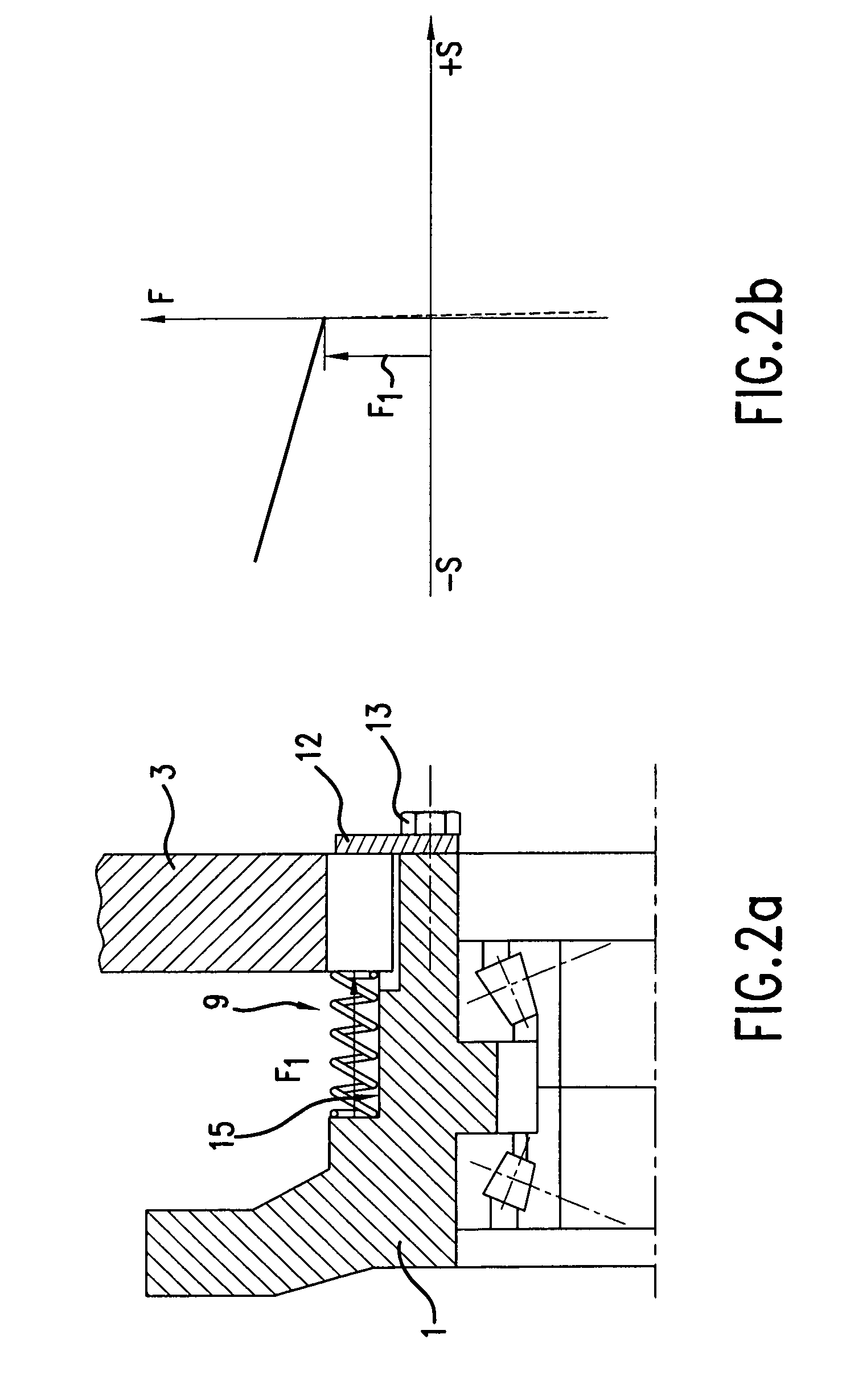

[0043] In FIG. 1, a brake disk for commercial vehicles, which is here configured, by way of example, as a fixed-caliper brake, is represented, which has a brake caliper 2 which is configured as a fixed caliper and reaches over a brake disk 3, which is disposed in an axially displaceable and torsionally secure manner on a vehicle part configured as an axle flange 1. The fixed caliper 2 is fixed immovably on the axle flange 1.

[0044] In the fixed caliper 2 there is disposed a brake application device 16, actuable by a piston rod of a brake cylinder and having an eccentrically mounted swivel lever 17, which brake application device is designed and constructed such that, when the swivel lever 17 is pivoted, pressure pieces (here not recognizable in detail) on this side of the brake disk 3 (referred to as the brake application side) are displaced parallel to the brake disk axis and press a brake shoe 4 disposed on the brake application side against the brake disk 3, which latter, if the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com