Sink spray scrubber

a scrubber and spray technology, applied in the field of spray scrubbers, can solve the problems of inability to scrubbing, time-consuming and inefficient procedures, and inability to clean the surface of the scrubber, and achieve the effects of convenient attachment and detachable, improved cleaning effect, and improved cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

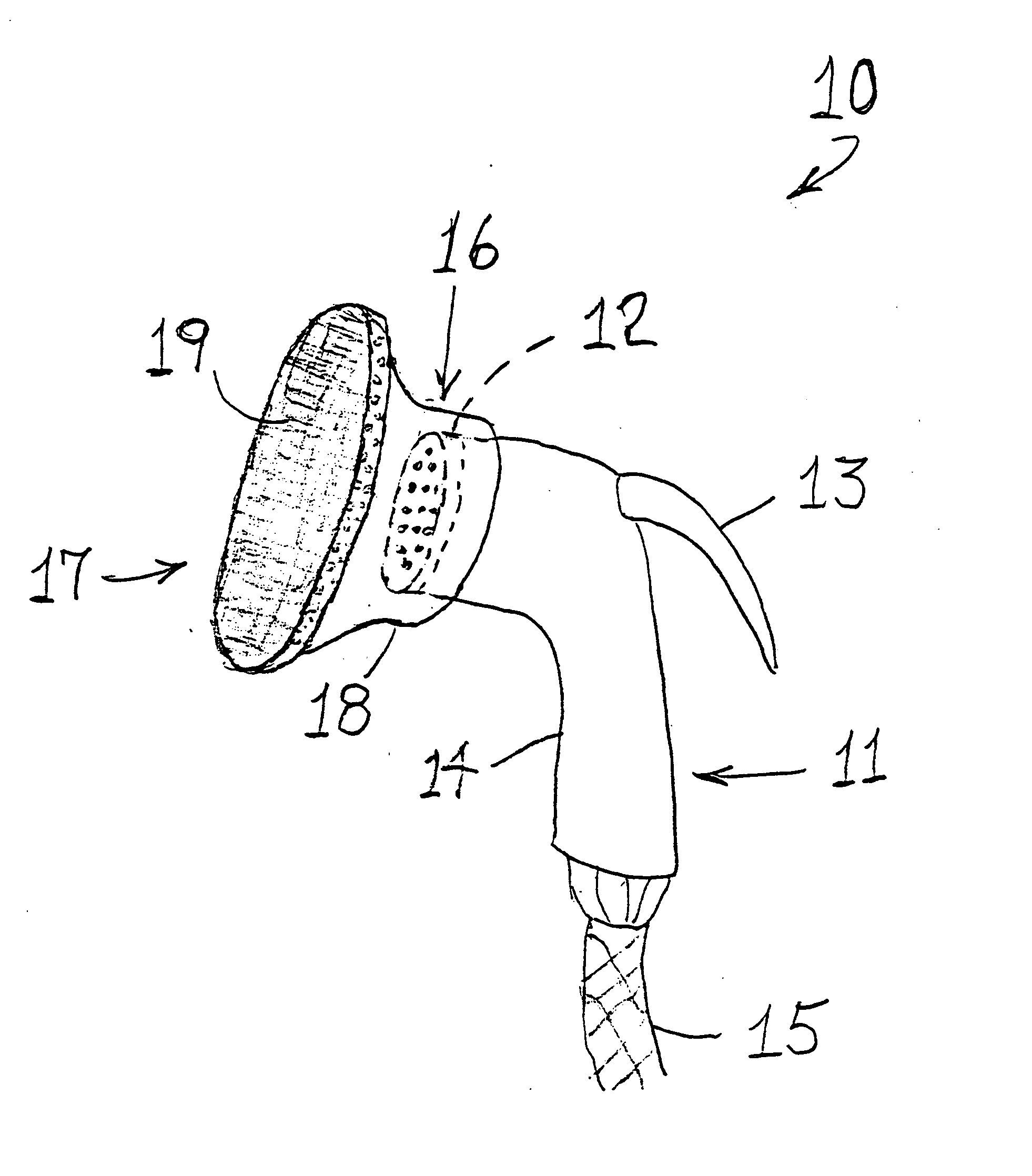

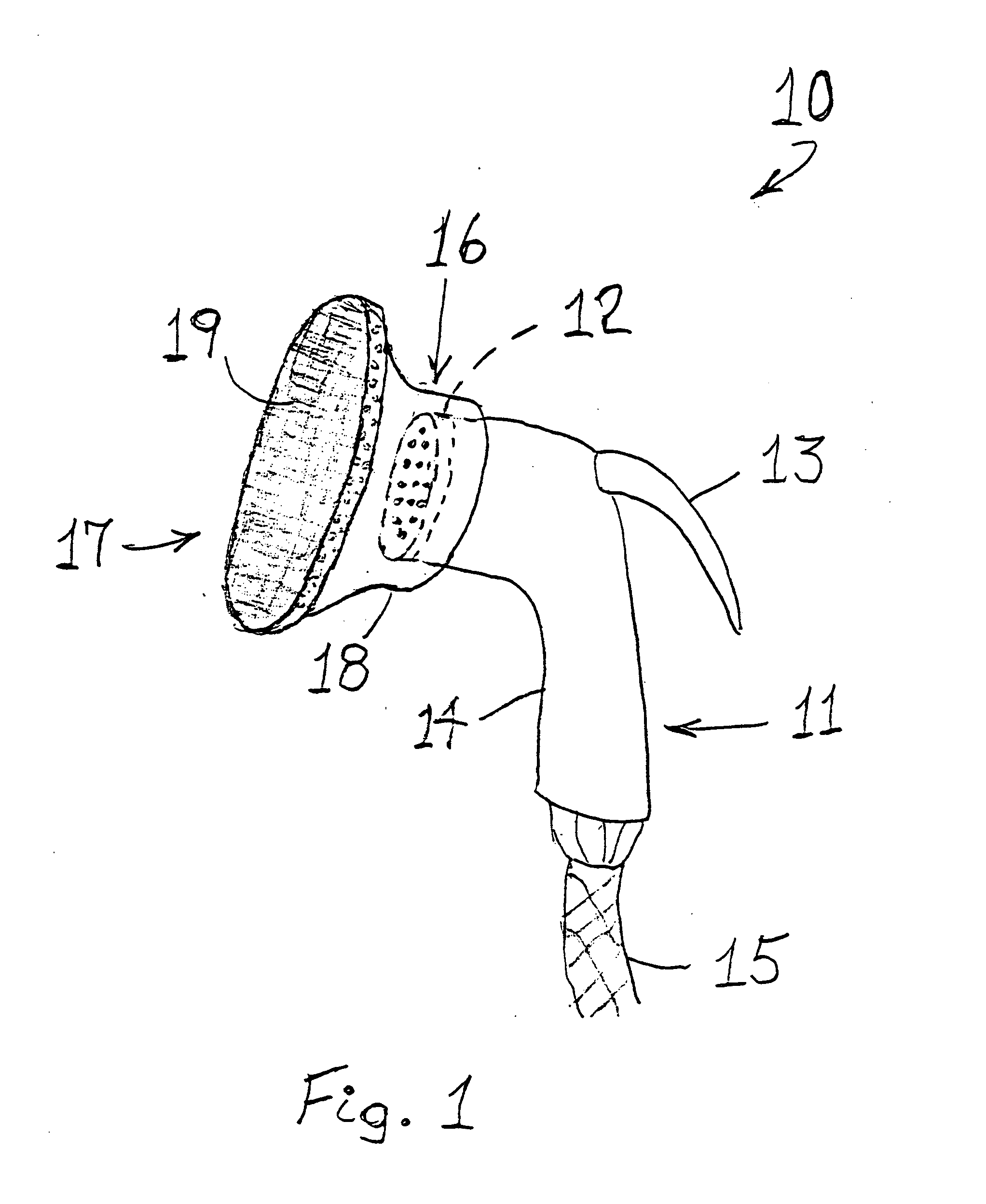

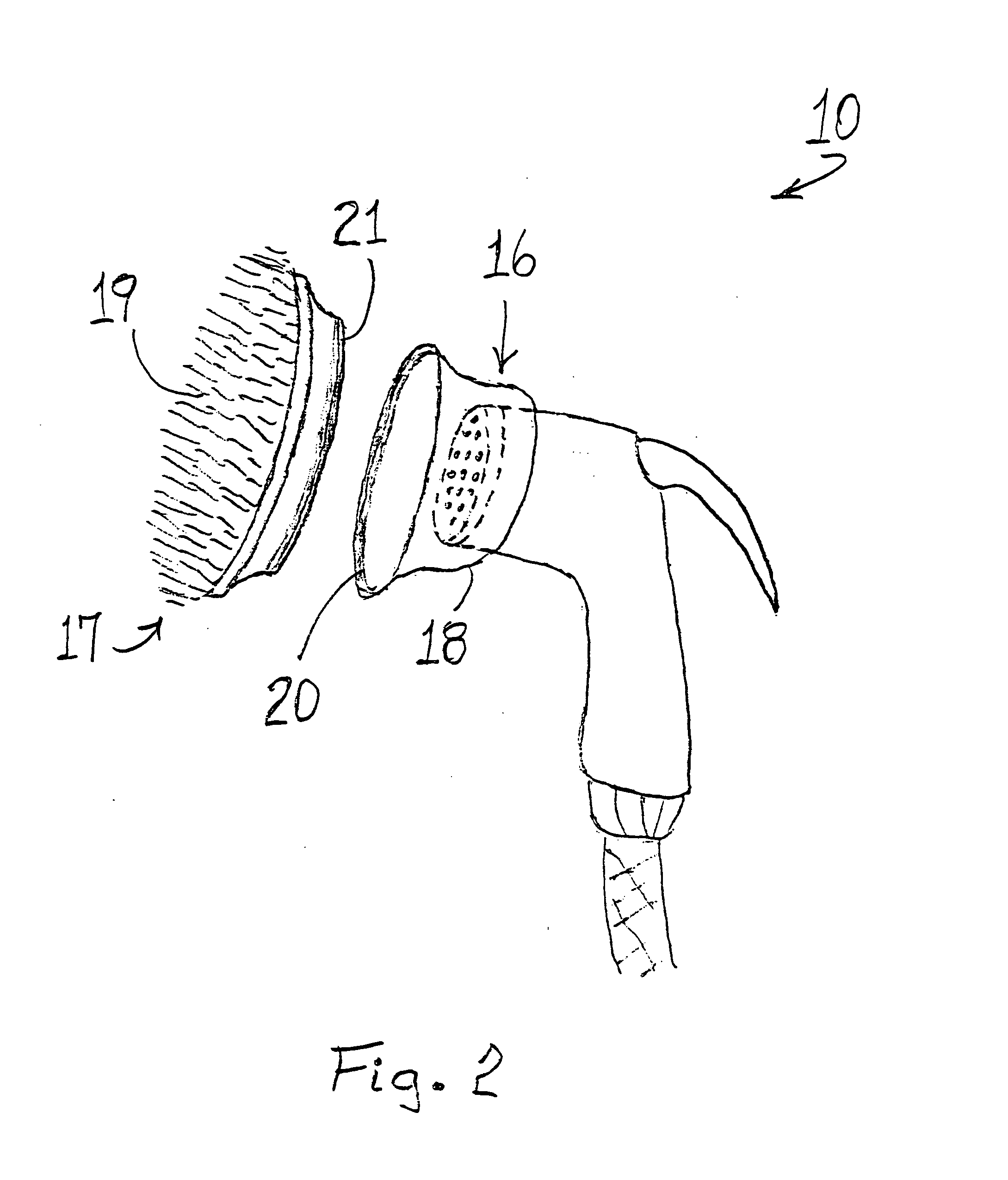

[0017]FIG. 1 and FIG. 2 depict a single-component embodiment and a dual-component embodiment of the present invention 10, respectively. Referring to FIG. 1, a sink spray scrubber having the features of the present invention 10 attaches to a standard sink sprayer 11, which comprises a nozzle 12, an actuating arm 13, a handle 14, and a hose 15.

[0018] The sink spray scrubber 10 consists of an attachment element 16 and a scrubbing element 17. The attachment element 16 comprises an attaching means 18 for fastening the scrubber 10 to the nozzle 12 in a secure and water-tight manner. The attaching means 18 comprises an expandable sleeve or collar, fabricated of an elastic plastic or rubber material, which is sized to slip over the nozzle 12 and form a water-tight seal between the nozzle 12 and the scrubbing element 17.

[0019] In the single-component embodiment of the present invention 10, as depicted in FIG. 1, the attachment element 16 is integrated as a single unit with the scrubbing el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com