Systems and methods of constructing, assembling, and moving modular washrooms

a technology of modular washrooms and washrooms, which is applied in the field of systems and methods of constructing, assembling, and moving modular washrooms, can solve the problems of significant revenue loss for developers and tenants, delay in opening a new business in an otherwise usable building unit, owner and tenant, etc., and achieves the effect of reducing the assembly time and being easily and quickly moved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention will now be described with reference to the accompanying Figures, wherein like numerals refer to like elements throughout. The terminology used in the description presented herein is not intended to be interpreted in any limited or restrictive manner, simply because it is being utilized in conjunction with a detailed description of certain specific embodiments of the invention. Furthermore, embodiments of the invention may include several novel features, no single one of which is solely responsible for its desirable attributes or which is essential to practicing the inventions described herein.

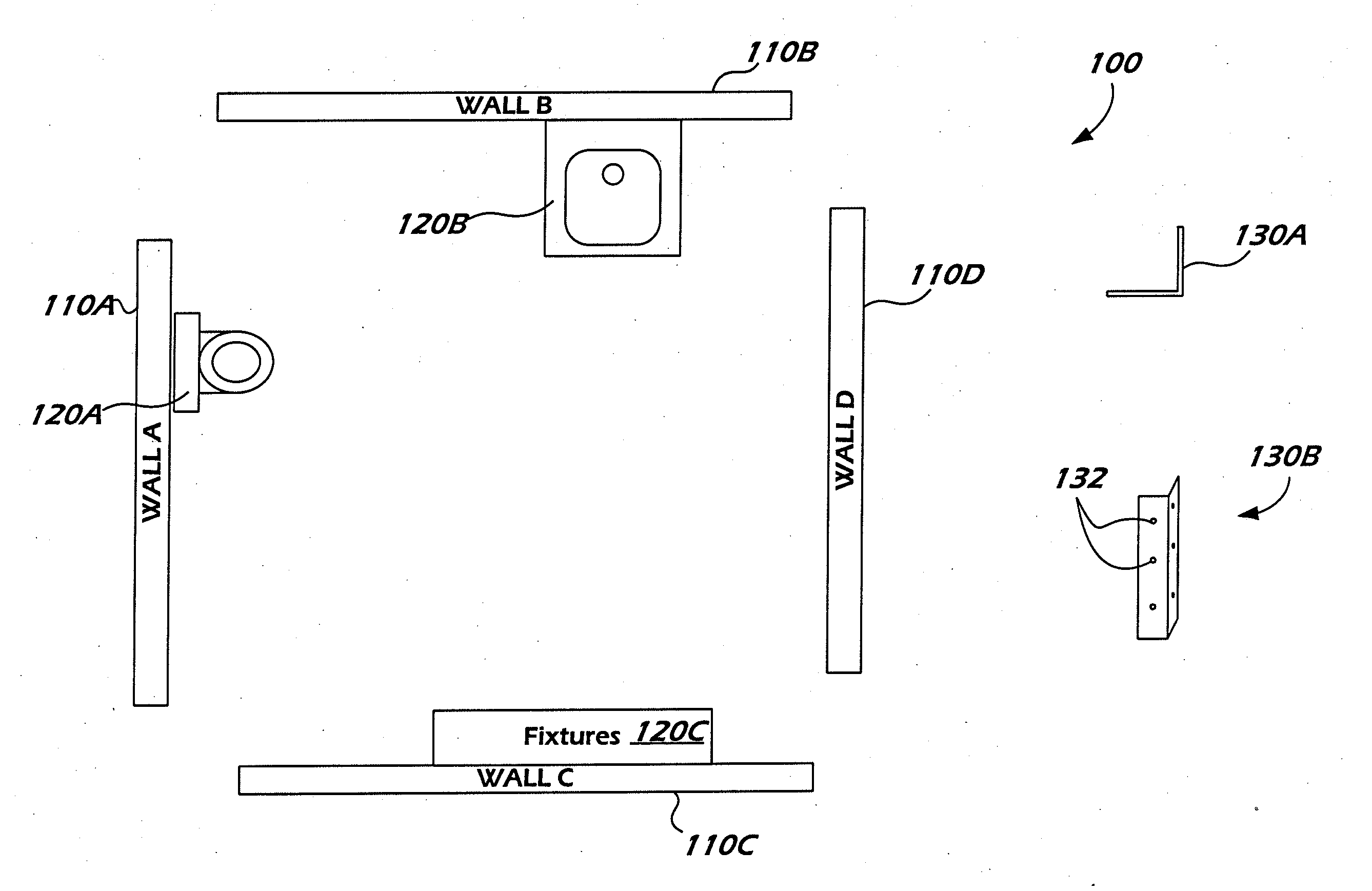

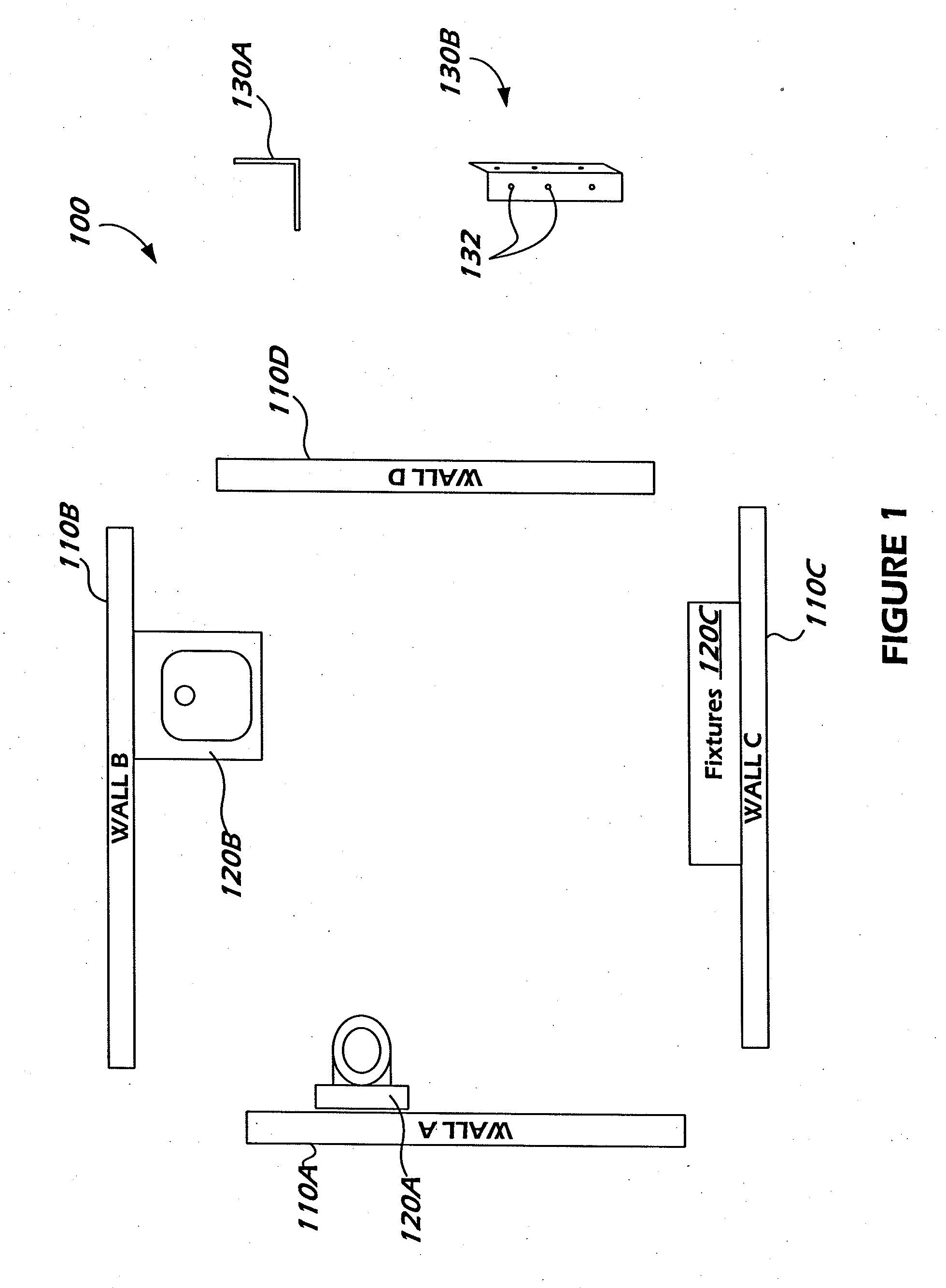

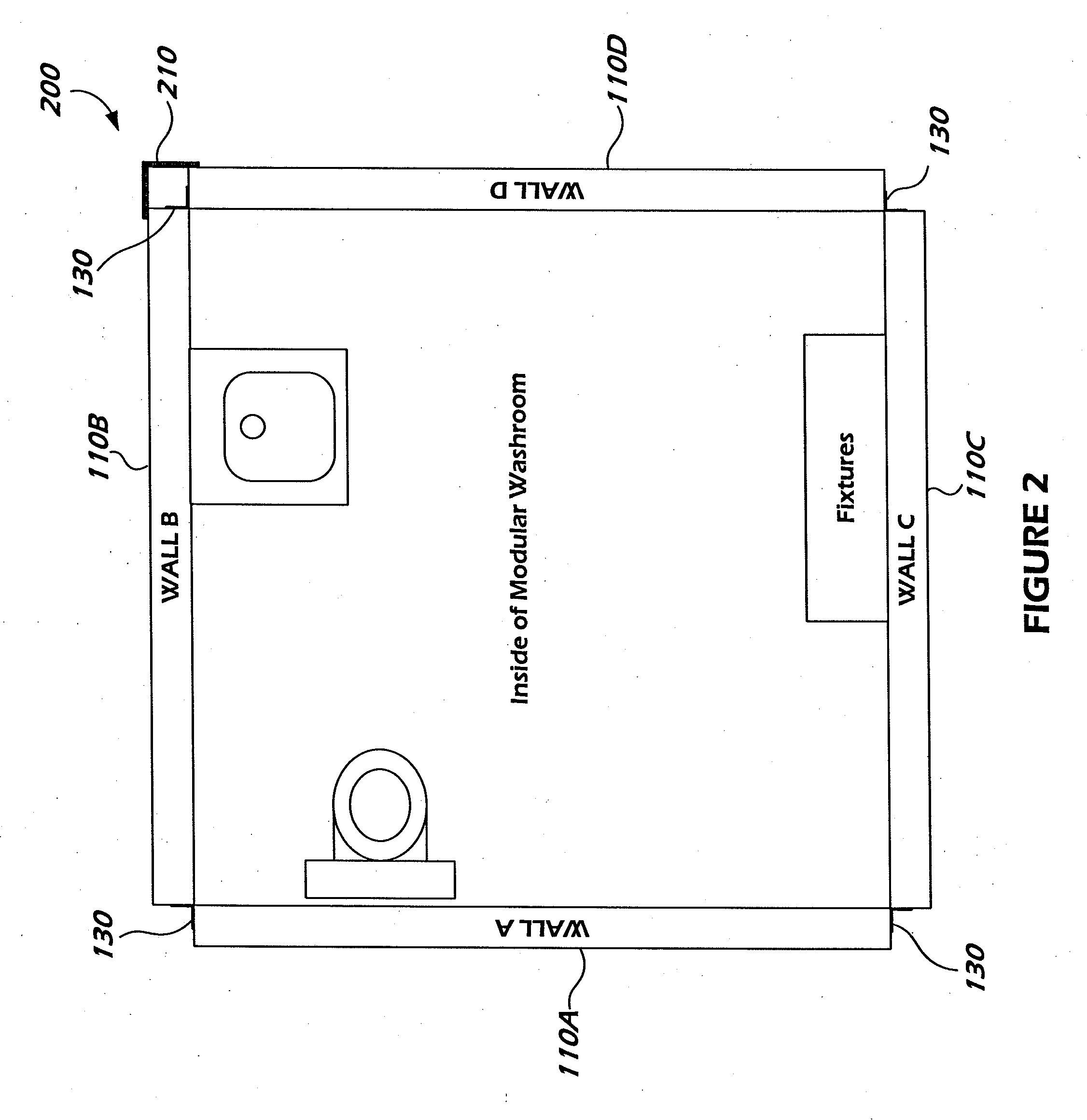

[0024]1FIG. 1 is a diagram of components of an exemplary modular washroom. FIG. 1 illustrates multiple walls 110A-110D, where some of the walls include fittings for installing fixtures 120A-120C to the walls 110. In particular, FIG. 1 illustrates a toilet 120A that may be attached to a water valve installed in wall 110A, a sink 120B that may be attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com