Axial void fraction distribution measurement method and neutron multiplication factor evaluating method

a technology of axial void fraction and measurement method, which is applied in the direction of nuclear elements, greenhouse gas reduction, nuclear reactors, etc., can solve the problems of not being able to apply the above-described technique to an operating nuclear reactor, not being able to make a report on an actual measurement of the void fraction distribution in the core of a commercial bwr, and not being able to achieve the effect of actual measurement of the void fraction distribution in an operating commercial nuclear reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0110] [First Embodiment]

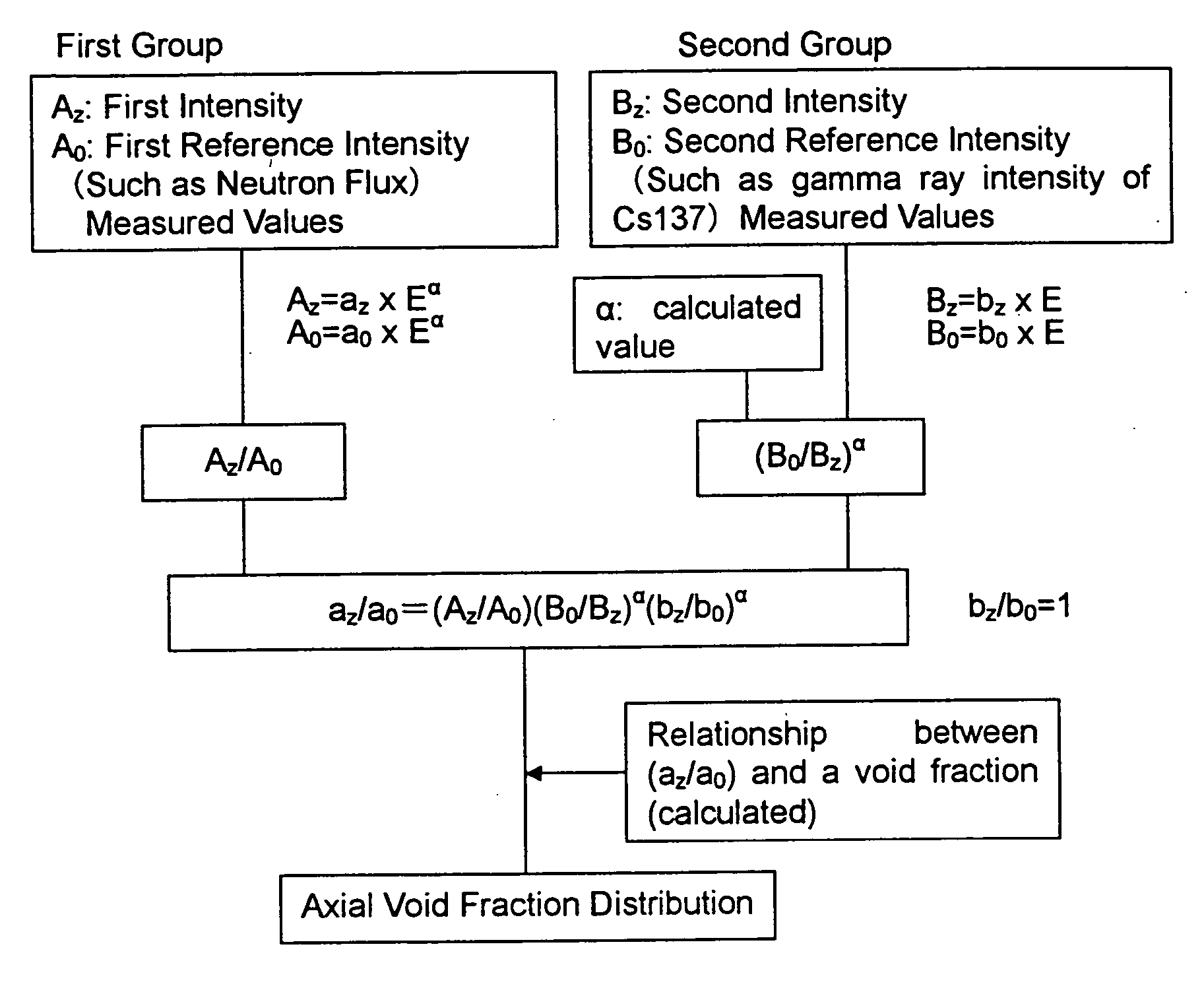

[0111]FIG. 1 is a flow chart of an axial void fraction distribution measurement method according to the first embodiment of the present invention.

[0112] In this embodiment, as the first intensity Az, a neutron emission rate Sz and So expressed as Sz=az×Eα or So=ao×Eα is used. And as the second intensity Bz and Bo, gamma ray intensity yz and yo expressed as yz=gz×Eα or yo=go×Eα is used.

[0113] Then, the ratio (az / ao) is expressed as;

(az / ao)=(Sz / So)(yo / yz)α(gz / go)α.

[0114] Based on the value of (az / ao) and the relationship between (az / ao) and a void fraction evaluated otherwise, a void fraction of the fuel is evaluated.

[0115] Also a correlation function representing a relationship between (az / ao) and a void fraction is derived from computations. The void fraction experienced at each axial position of the fuel assembly, i.e., the void fraction distribution is obtained from this correlation function and (az / ao) derived from the first and second intensities of t...

second embodiment

[0120] [Second Embodiment]

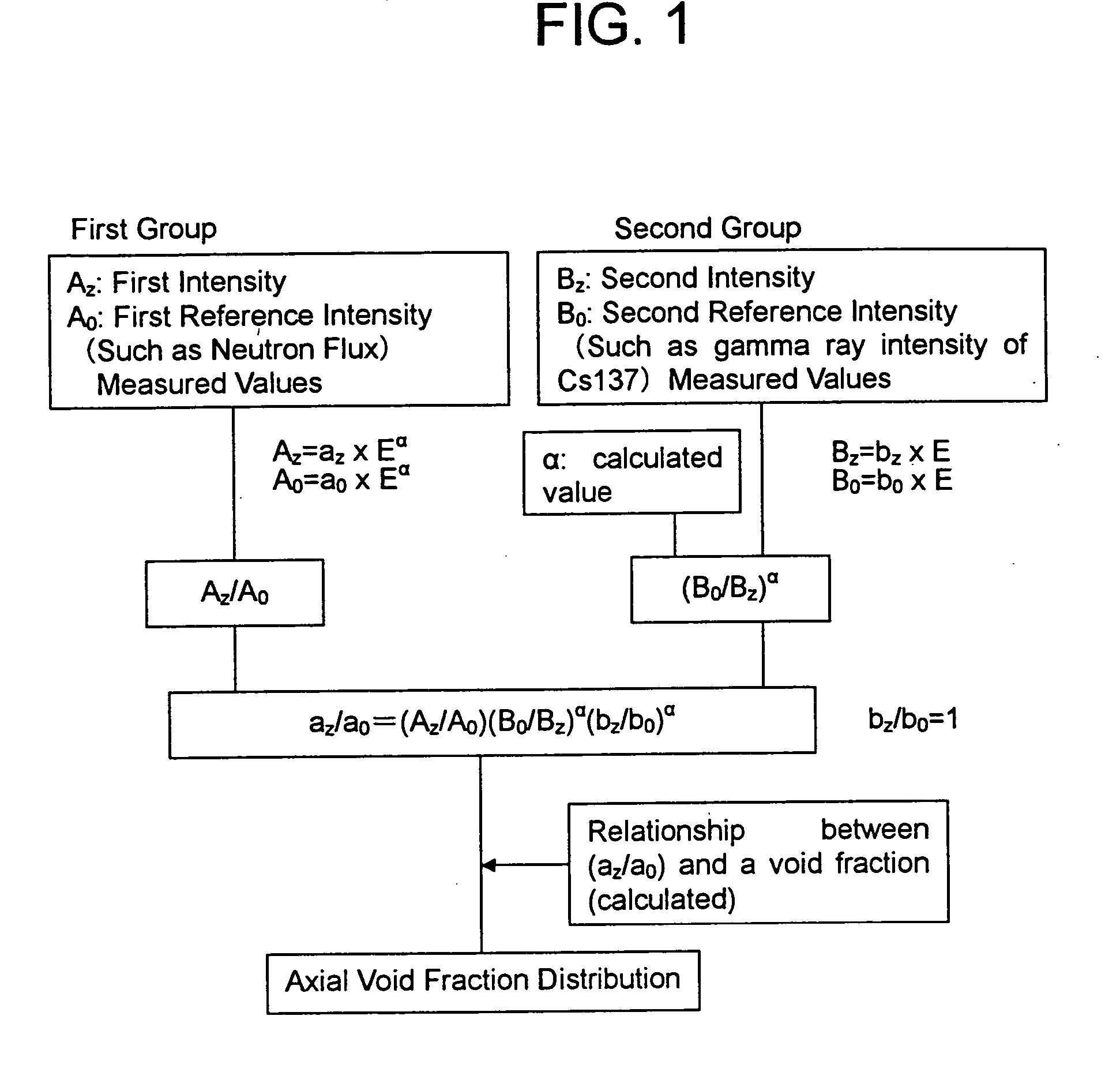

[0121]FIG. 2 is a flow chart of an axial void fraction distribution evaluation method according to the second embodiment of the present invention.

[0122] This embodiment is different from the first embodiment in a point that the values of (φz / φo) are corrected for the contribution of the axial variation of the neutron multiplication factor by a standard neutron multiplication factor distribution obtained from the design calculations.

[0123] As described above, the effect is rather small relative to (φz / φo−1) in a BWR fuel assembly so that no problem arises even if the value obtained by the design calculation is used, because the effect of the neutron multiplication factor is about 10 to 20%. It is well known that the neutron flux or neutron counting rate (φ) has a relationship of φ=c S / (1−k), where k is a neutron multiplication factor, S is a neutron emission rate, and c is a proportionality constant. This relation is used in this embodiment.

[0124] The pro...

third embodiment

[0125] [Third Embodiment]

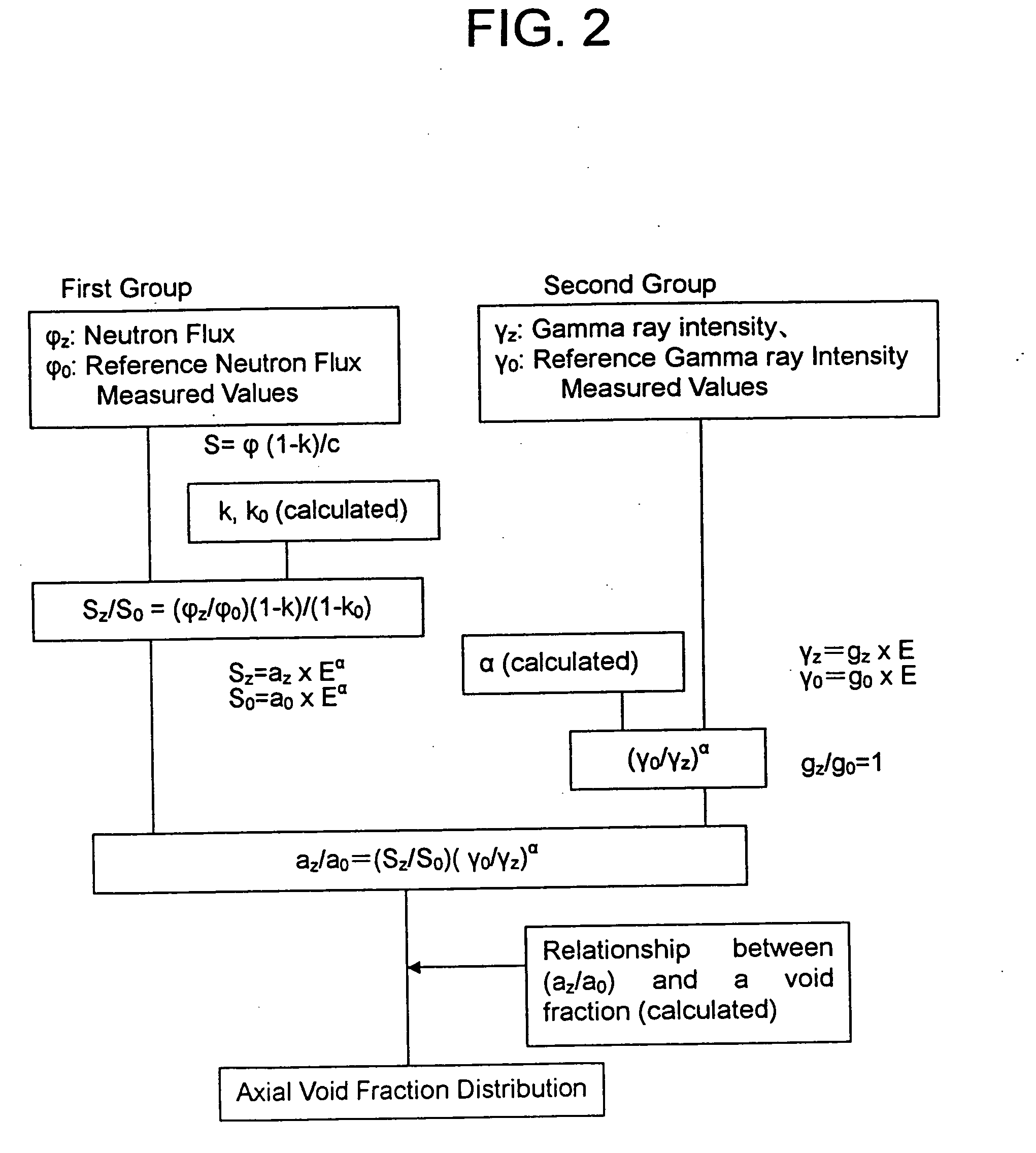

[0126]FIG. 3 is a flow chart of an axial void fraction distribution evaluation method according to the third embodiment of the present invention.

[0127] A difference of this embodiment from the second embodiment is that (φz / φo) is corrected for the contribution of an axial variation of the neutron multiplication factor based on a fuel assembly averaged exposure that seems to be available most easily from the operator of the reactor.

[0128] This method of determining a neutron multiplication factor (k) comprising the steps of correcting an estimated void fraction distribution by measured values repeatedly, determining the infinite multiplication factor (k∞) that depends on the exposure and corresponds to the void fraction, and then determining k.

[0129] The procedure of this embodiment is described in detail below.

[0130] An axial neutron flux (or the axial neutron counting rate) distribution and a gamma ray intensity distribution, as well as (yo / yz)α can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com