Seat pad

a seat pad and seat technology, applied in the field of seat pads, can solve the problems of not providing a means, designs folded with a fabric backing may be reversible but not stable, and the type of non-attached gripping surfaces could become a safety hazard,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

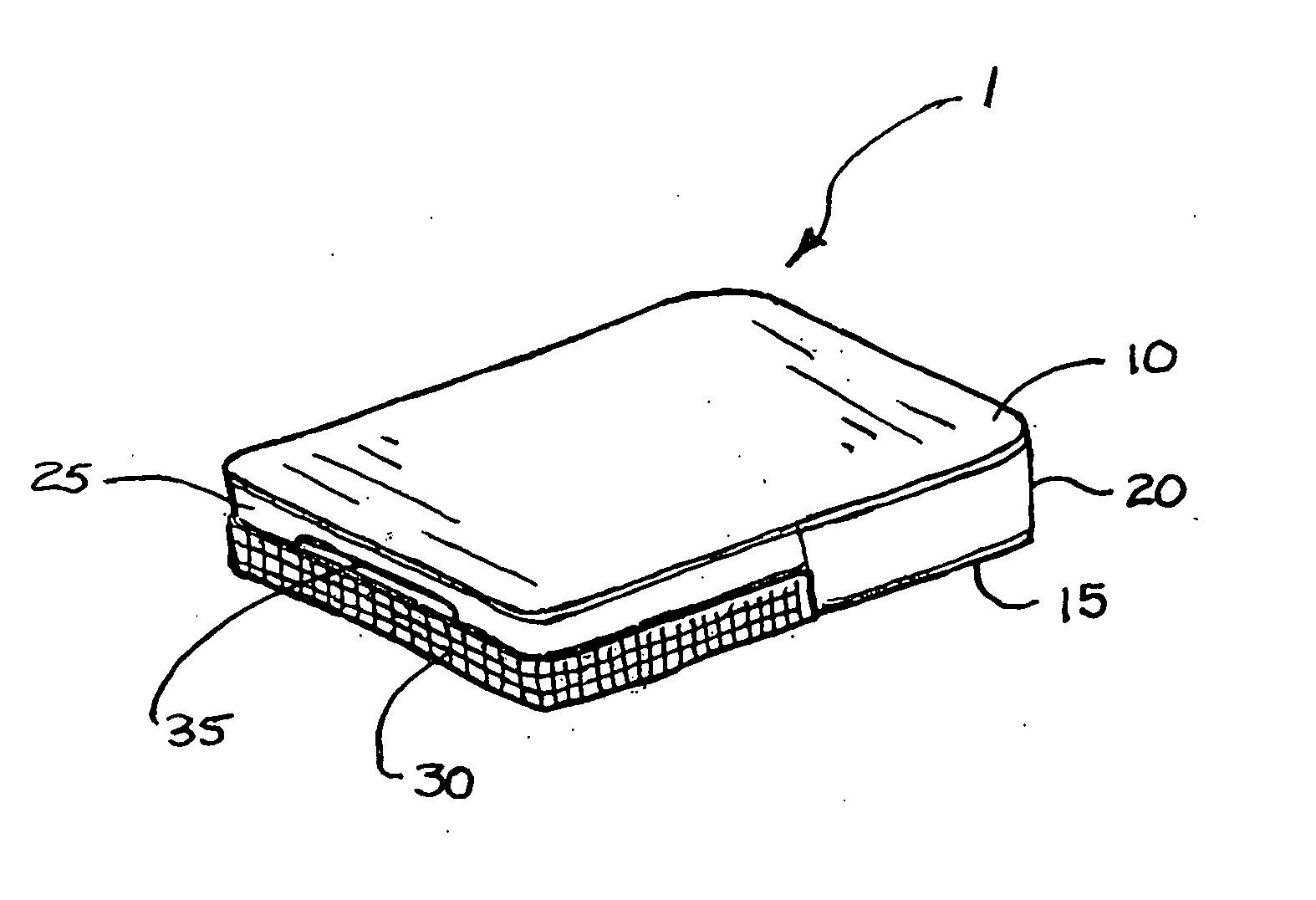

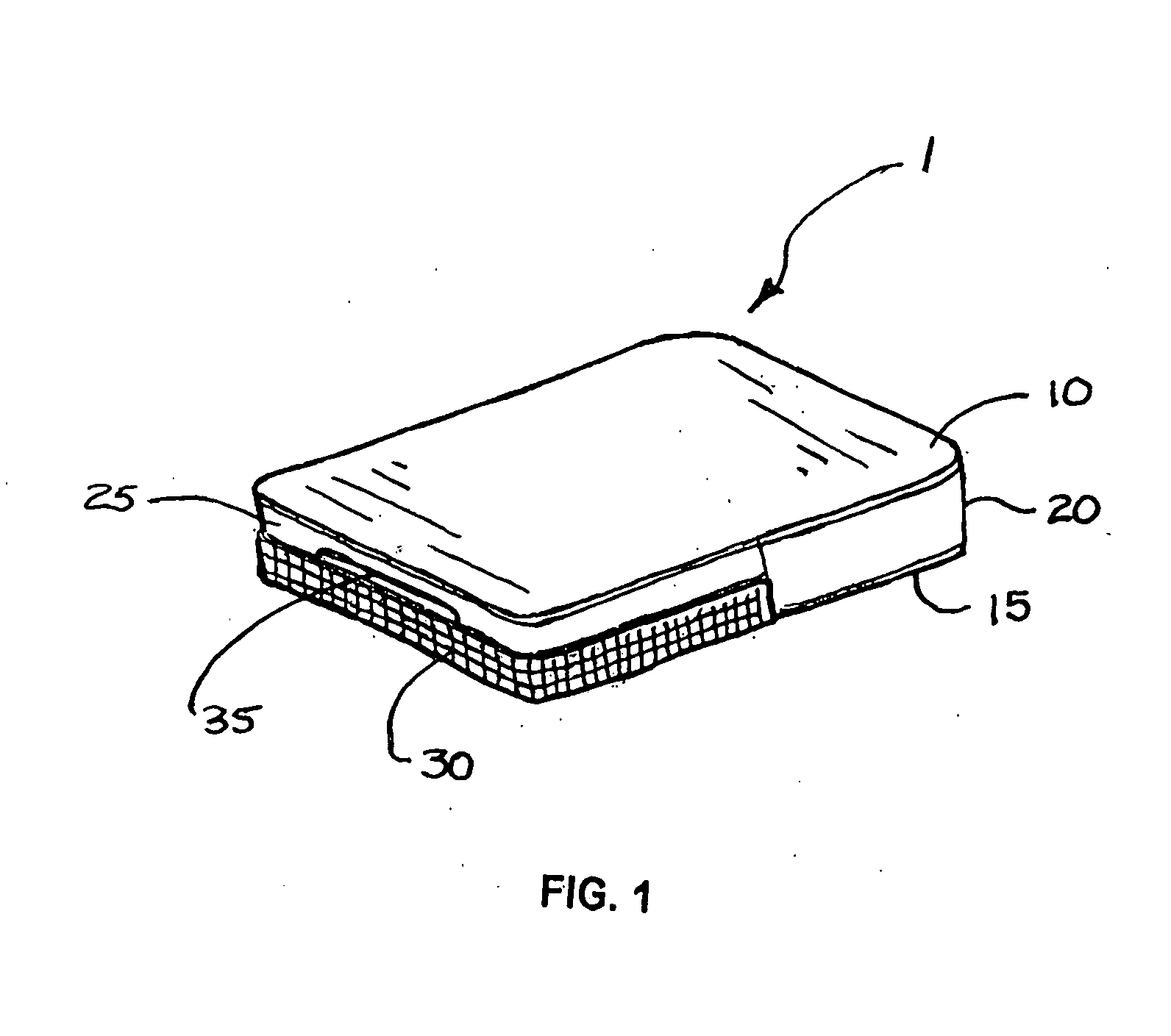

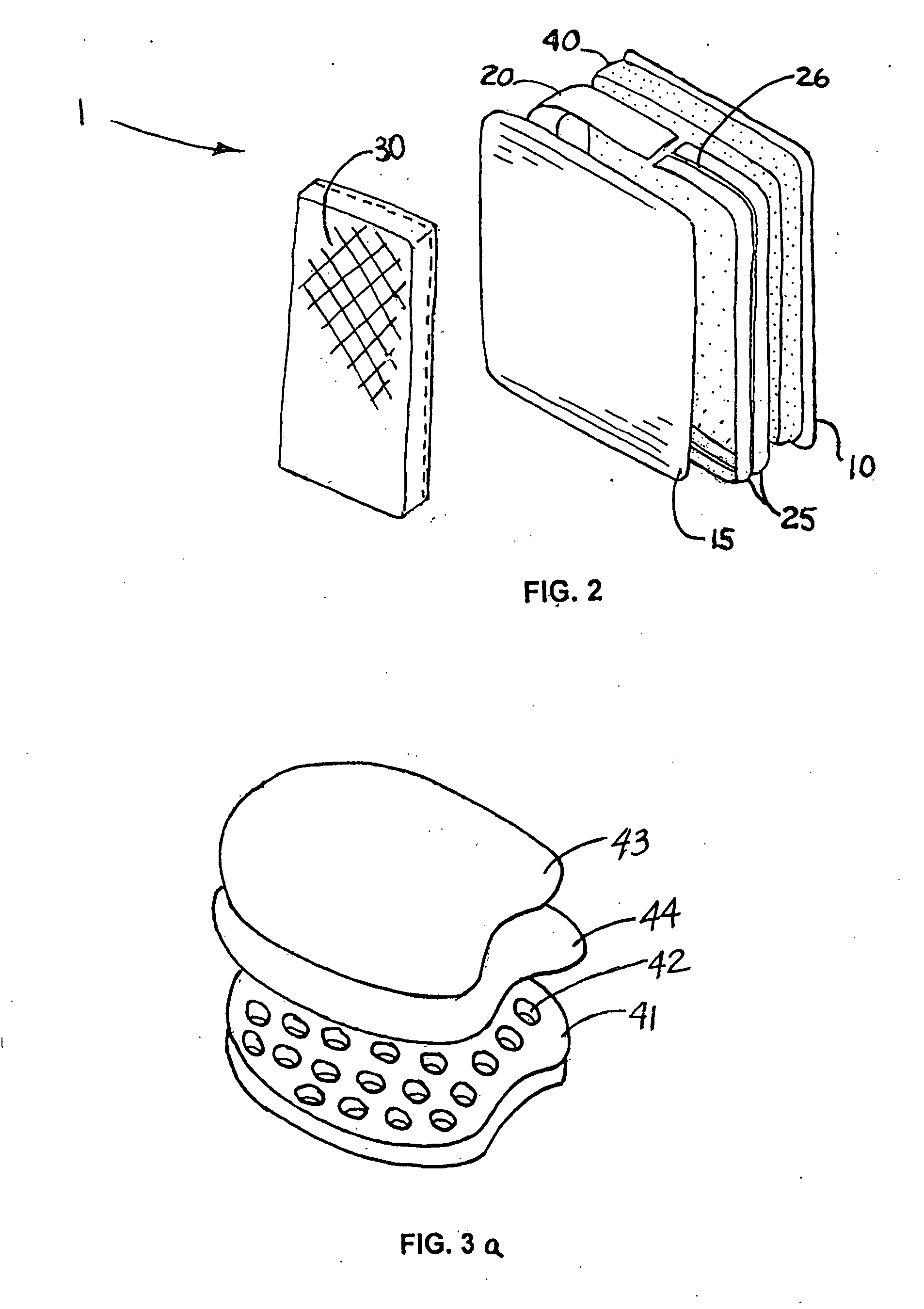

[0030] While the invention described is susceptible of embodiment in many different forms, they are shown in the drawing, specification and herein described in the detailed specific embodiments and is not intended to be limited to the specific embodiments illustrated. Referring to FIG. 1 the seat pad 1 of the present invention is constructed of a first upper panel 10, and a second lower panel 15 comprising a semi-rigid or resilient fabric like material. The first upper panel 10, and second lower panel 15 may provide different materials, colors, textures or a design that may be provided by other conventional methods. A third side panel component 20 is provided between the first upper panel 10, and second lower panel 15 to be attached at least a portion of the outer perimeter of upper panel 10, and lower panel 15. The third side panel 20 may be fixedly attached to the upper panel 10, and lower panel 15, to at least a portion of the outer periphery to form a three dimensional shape. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com