Sheet processing apparatus and image forming apparatus

a technology of image forming apparatus and processing apparatus, which is applied in the directions of transportation and packaging, thin material processing, and article delivery, etc., can solve the problems of increasing cost, complicating the apparatus configuration, and insufficient alignment, and achieves high efficiency and low cost. , the effect of enhancing the alignment property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

Staple Sort Mode

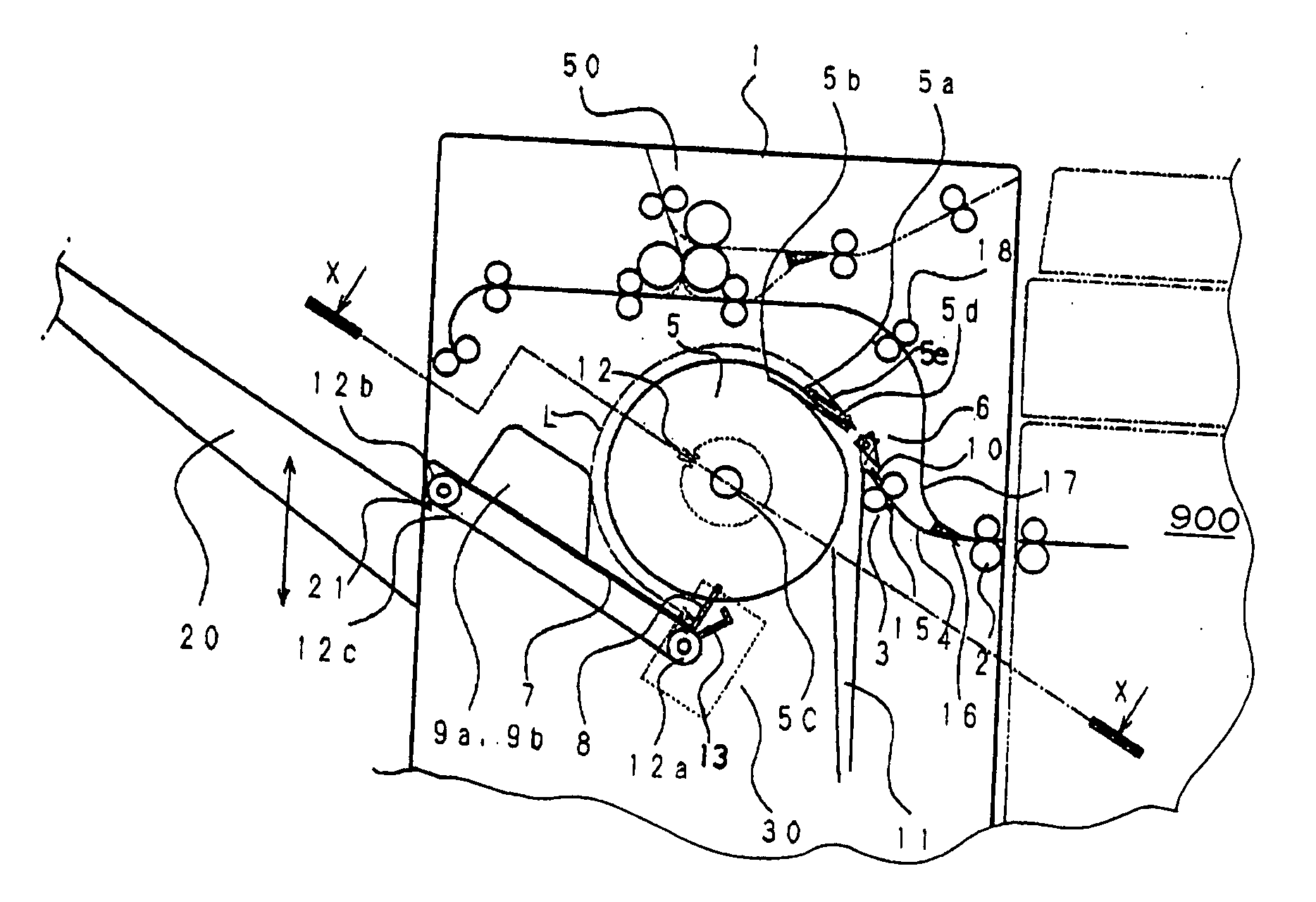

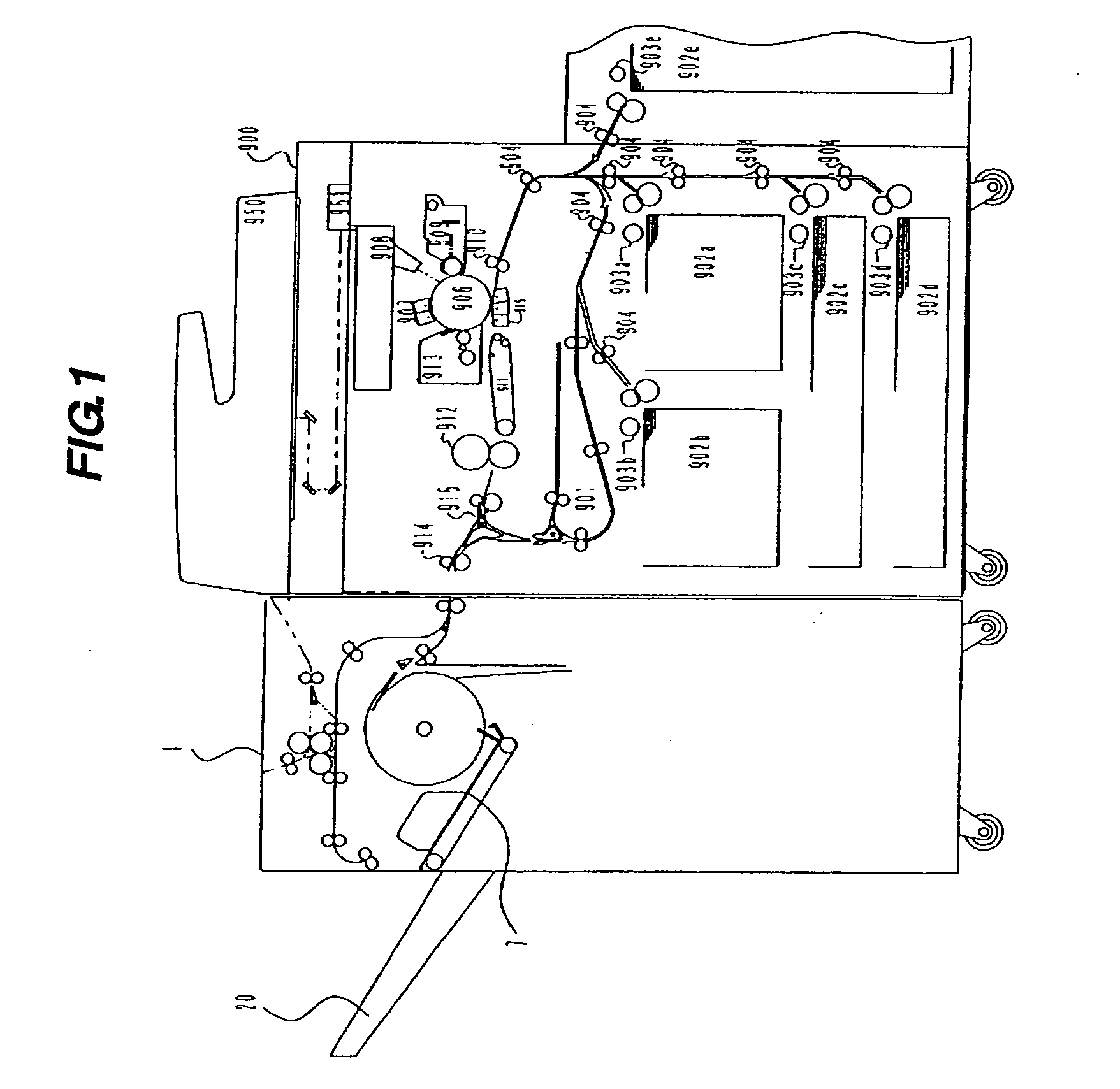

[0058] When the user specifies the staple sort mode (step: S1), the first sheet P1 formed with image shown with a broken line in the figure is discharged from the apparatus main body 900 of the image forming apparatus as shown in FIG. 10. The discharged sheet P1 is received by the entrance side rollers 2, 3 and conveyed to the conveyance paths 4, 10. The flappers 6 are at the position of the figure and convey the sheet P1 to the movement gripper 5. The movement gripper 5 is in a stopped state at the receiving position (step: S2). The movement gripper 5 is moved to the receiving position when not in the receiving position (step: S3). As the conveyance proceeds, the front end of the sheet P1 is guided to the gripper tapered surface 5d and enters the gripping portion 5a, and abuts against the abutment surface 5b of one of the two movement grippers 5 lined on the rotating shaft. The movement gripper 5 is still stopped over a predetermined time after the abutment, and the...

second embodiment

Sort Mode

[0071] The operation of when the sort mode in which the stapling is not performed is specified by the user will now be described. In this mode as well, two, or three or more sheets are stacked and accommodated in the processing tray 7 while being sequentially superimposed on the movement gripper 5, similar to the staple and sort mode. After the sheet of the last page is aligned, the stack conveying projection 13 immediately discharges the sheet bundle to the stack tray 20. Subsequently, the next subsequent sheet bundle is similarly divided and accommodated in the processing tray 7, but the aligning position in the sheet width direction is performed at a position different from the previous sheet bundle. This is so as to distinguish the previous sheet bundle when the subsequent sheet bundle is stacked in the stack tray 20. Therefore, the sheet bundle is stacked up to the last stack at the stack tray 20 while changing the aligning position in the sheet width direction on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com