Single device to create flame and extinguish flame

a single device and flame extinguishing technology, applied in extinguishing devices, burners, combustion types, etc., can solve the problems of reducing available oxygen, affecting the combustion process, so as to reduce available oxygen and reduce lingering odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

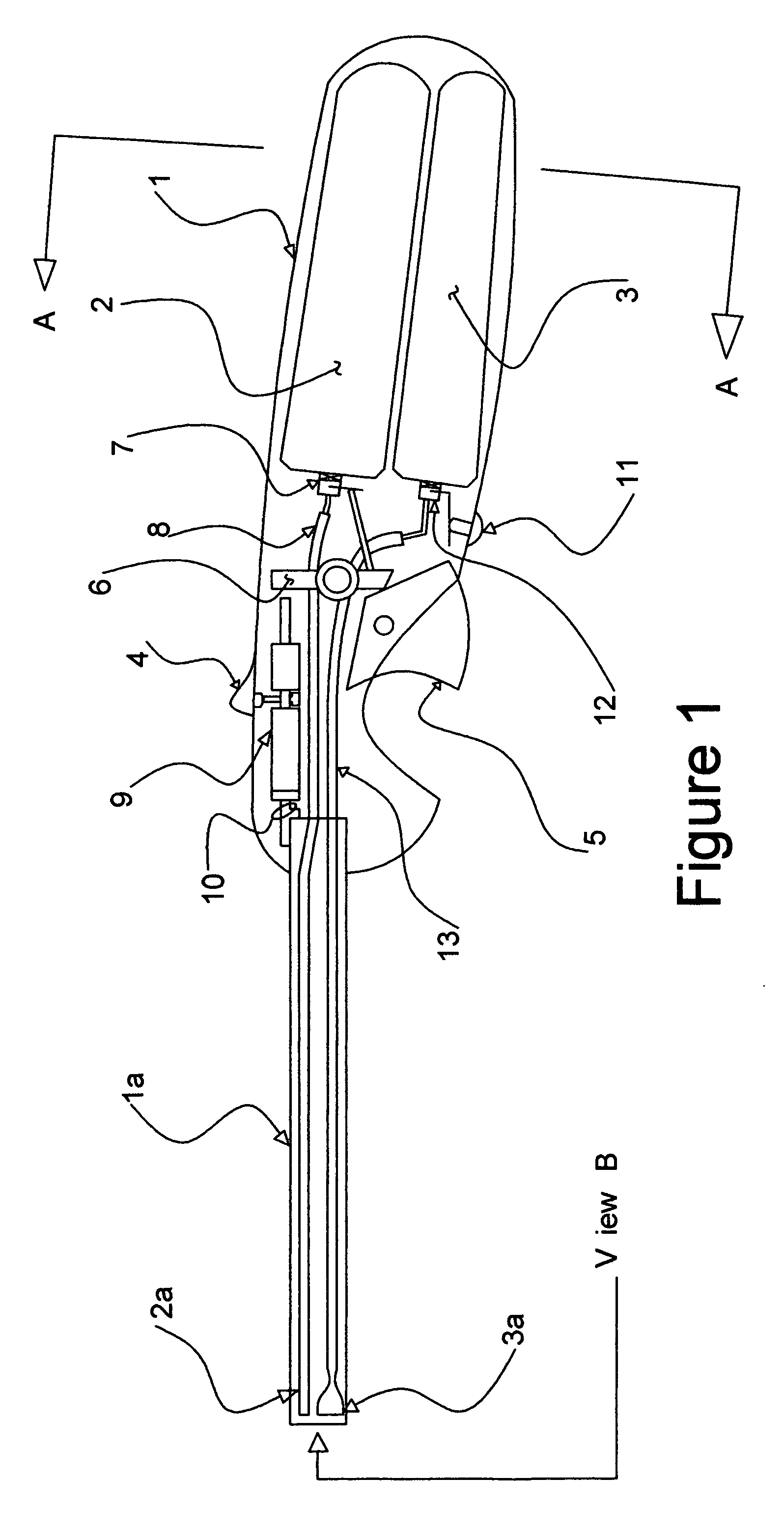

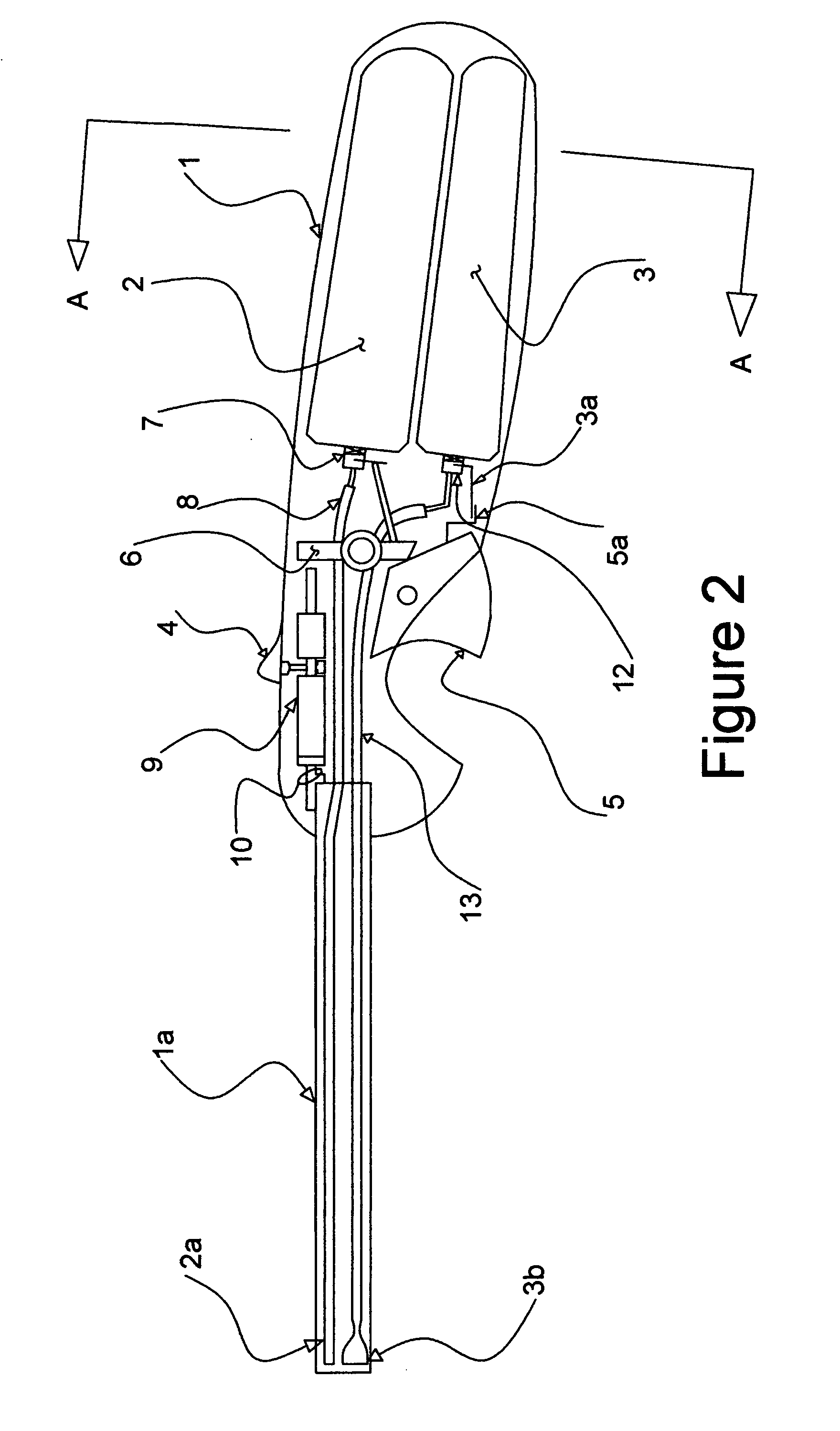

[0032] There exists a myriad configurations of “child proofing” and “triggering” schemes in utility lighters. Many involve pressing, twisting, squeezing and other manipulations to allow the lighter to light. What is shown is this embodiment is a simple “example” and not intended to be the invention. Also, the physical relationship between the components as depicted is not necessarily the only relationship but is represented as one of many typical ways the instant invention can be incorporated.

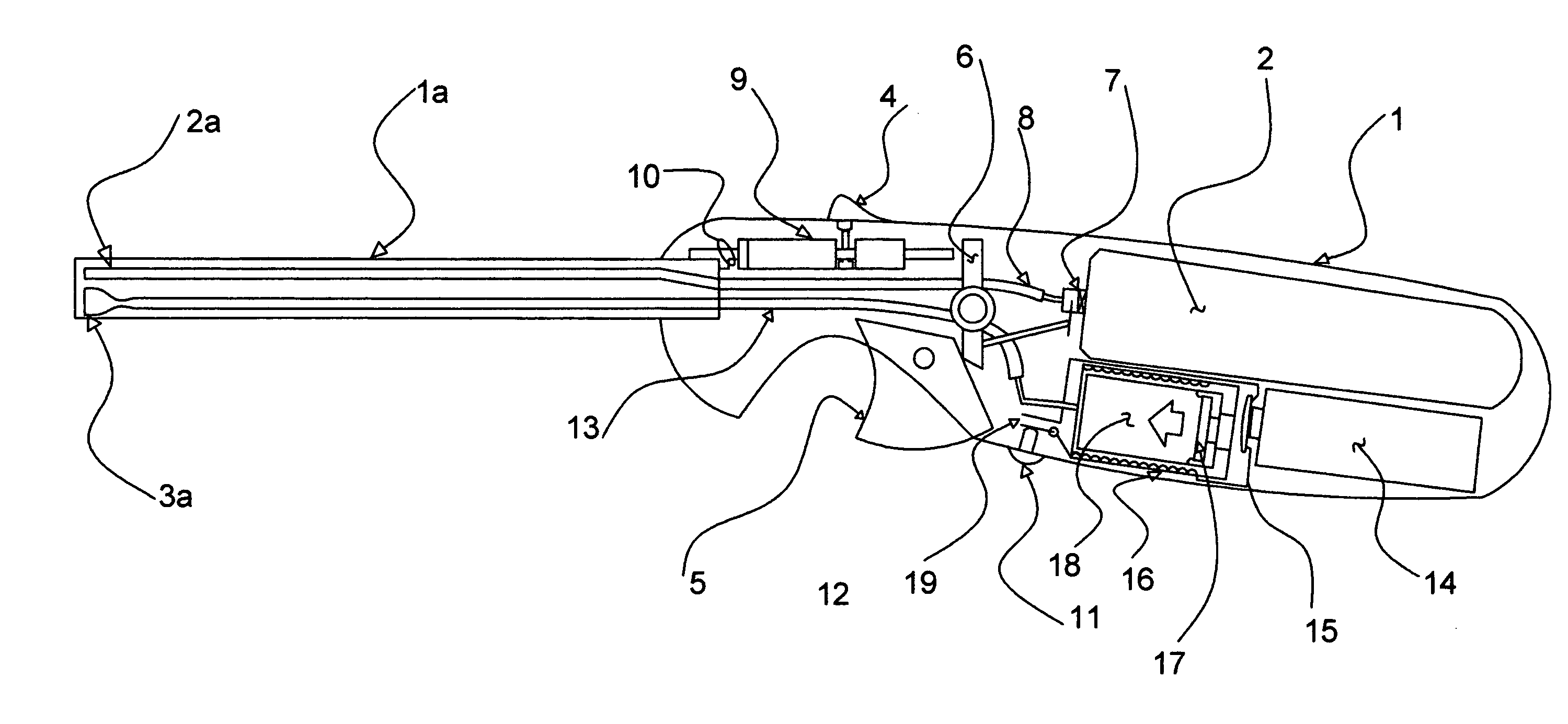

[0033]FIG. 1 describes the internal components of a typical utility lighter with the instant invention included. The shell housing 1 provides a grip and a platform for the components. In the handle 1 is various vessels one of which is a low pressure vessel 2 containing a flammable gas. The other vessel which part of the object of the present invention is a low pressure vessel 3 containing a flame extinguishing gas. Housing 1 is attached to a tubular extension 1a which house the capillary tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com