Safety toe cap base material structure for work shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

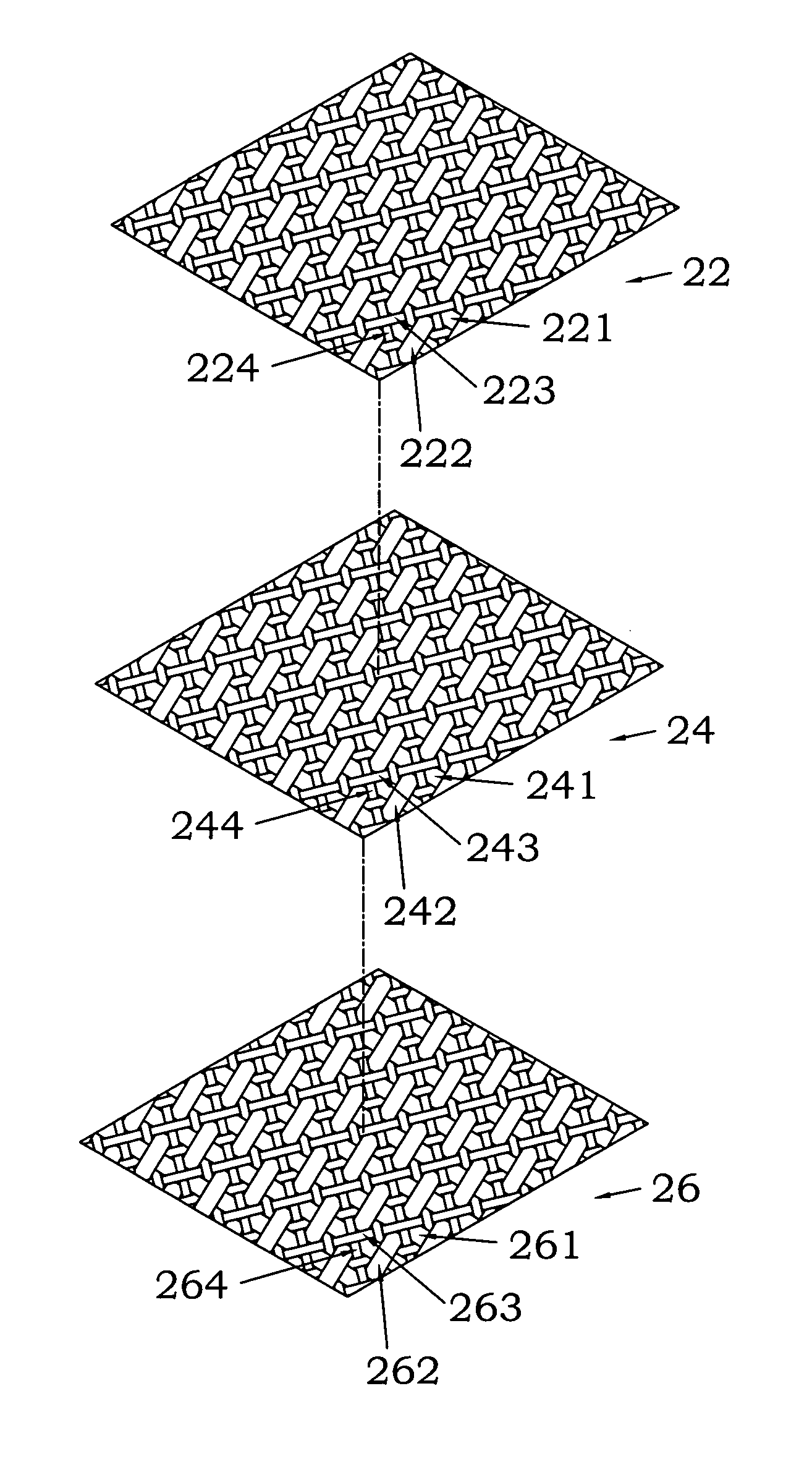

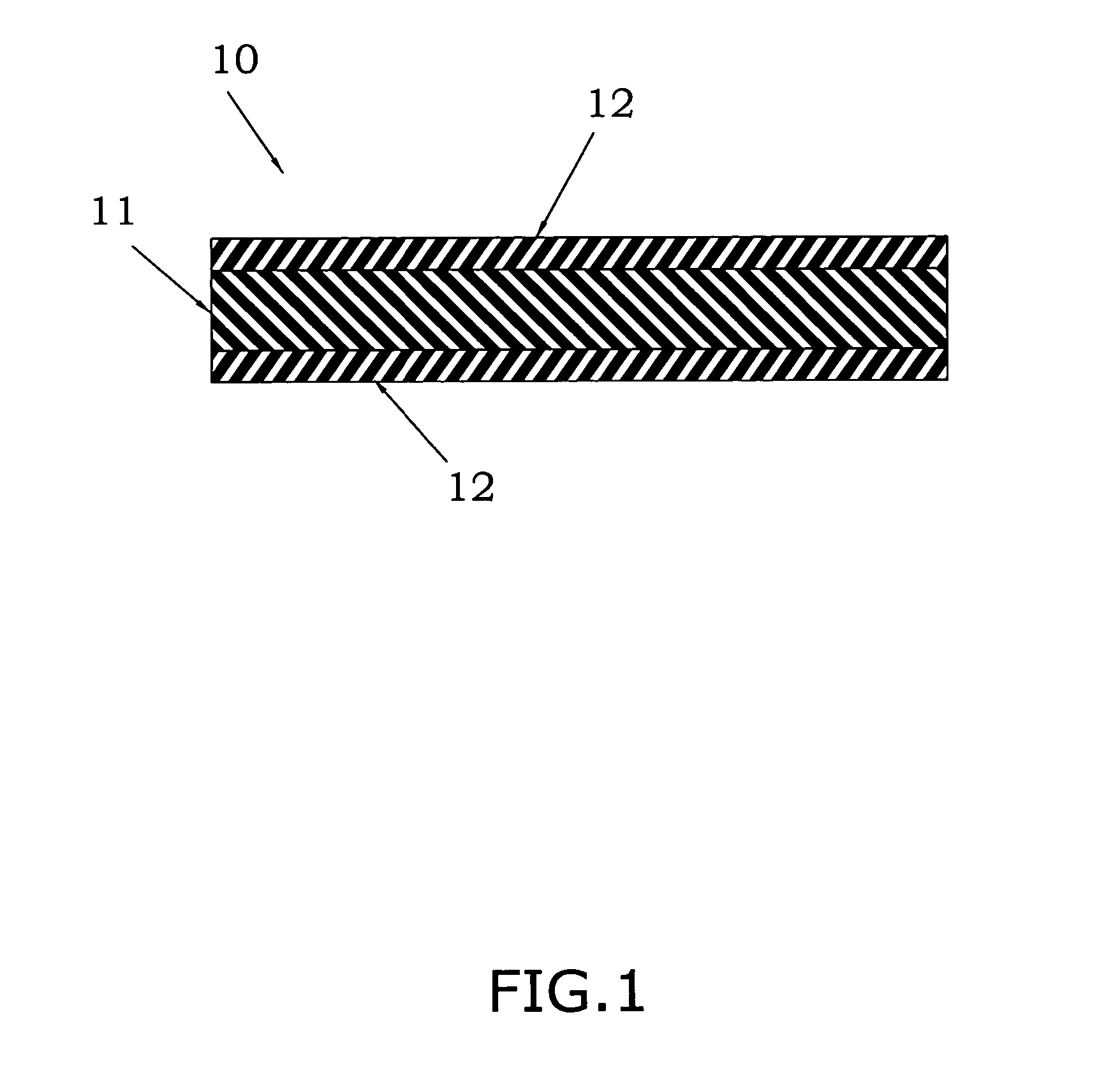

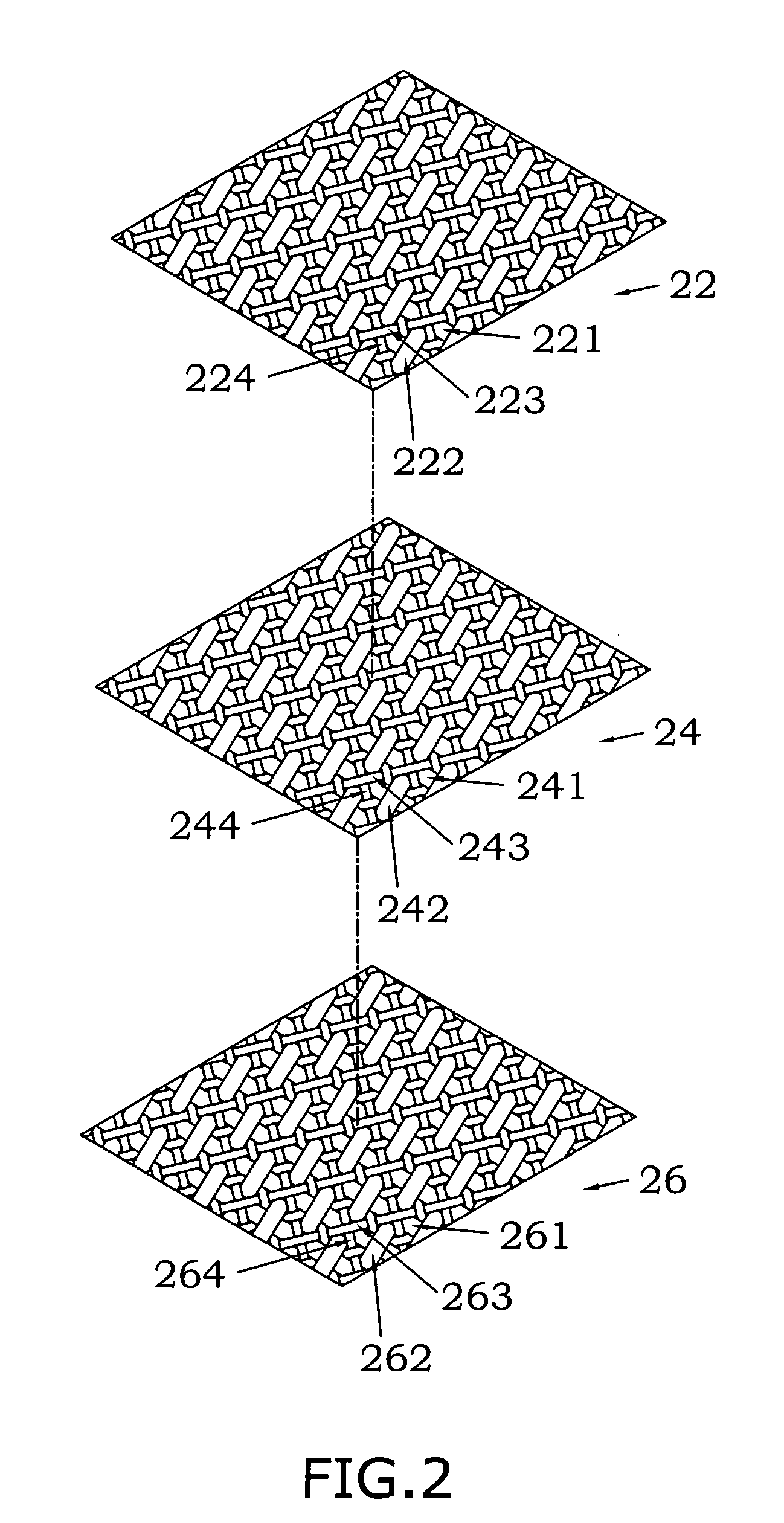

[0011] As indicated by FIG. 2˜FIG. 4, this invention provide work shoe safety toe cap base material structure 20, allow different strength requirement by choosing at least 3˜5 layers of fiber, and then use pressing method to bond together such fiber layers by hot press and form a base material structure. This invention in practice is using a first fiber layer 22, a second fiber layer 24 and a third fiber layer 26 forming three fiber layers structure, certainly can also rely on using different number of such fiber layers with same method as this invention to form a base material. But we point out clearly that base material apply with and made by same method as this invention is also belong to same technical category as this invention. However, each of such fiber layers 22, 24, 26 bring into practice under this invention comprise of molding filament material from strengthen fiber glass or thermoplastic resin, certainly also can be comprise of molding filament from other composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com