Knitting machines with air feed

a technology of air feed and knitting machine, which is applied in the field of knitting machines, can solve the problems of affecting the knitting process, unable to achieve the cleaning effect, and difficulty in accessing the cam, so as to reduce the air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

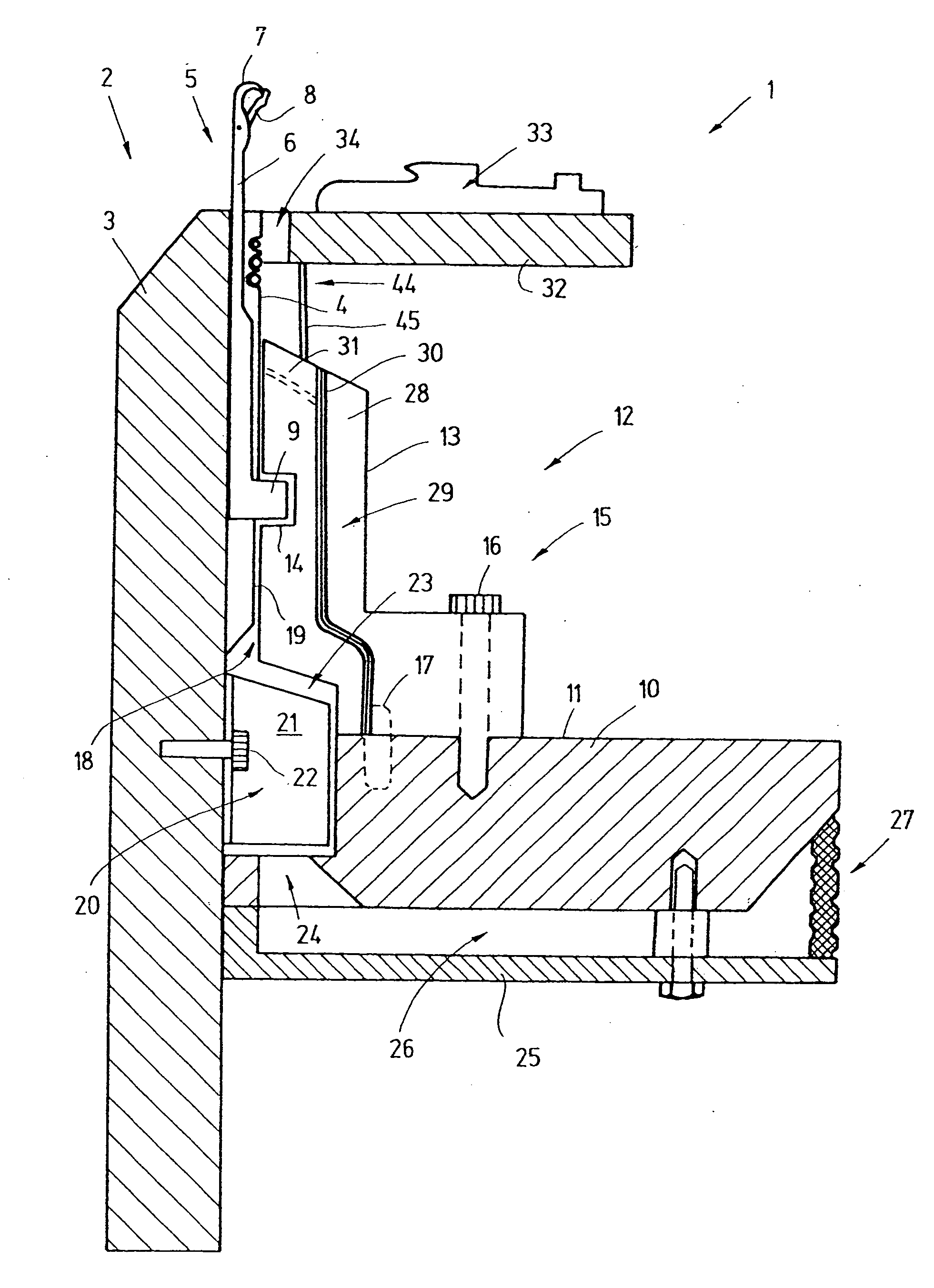

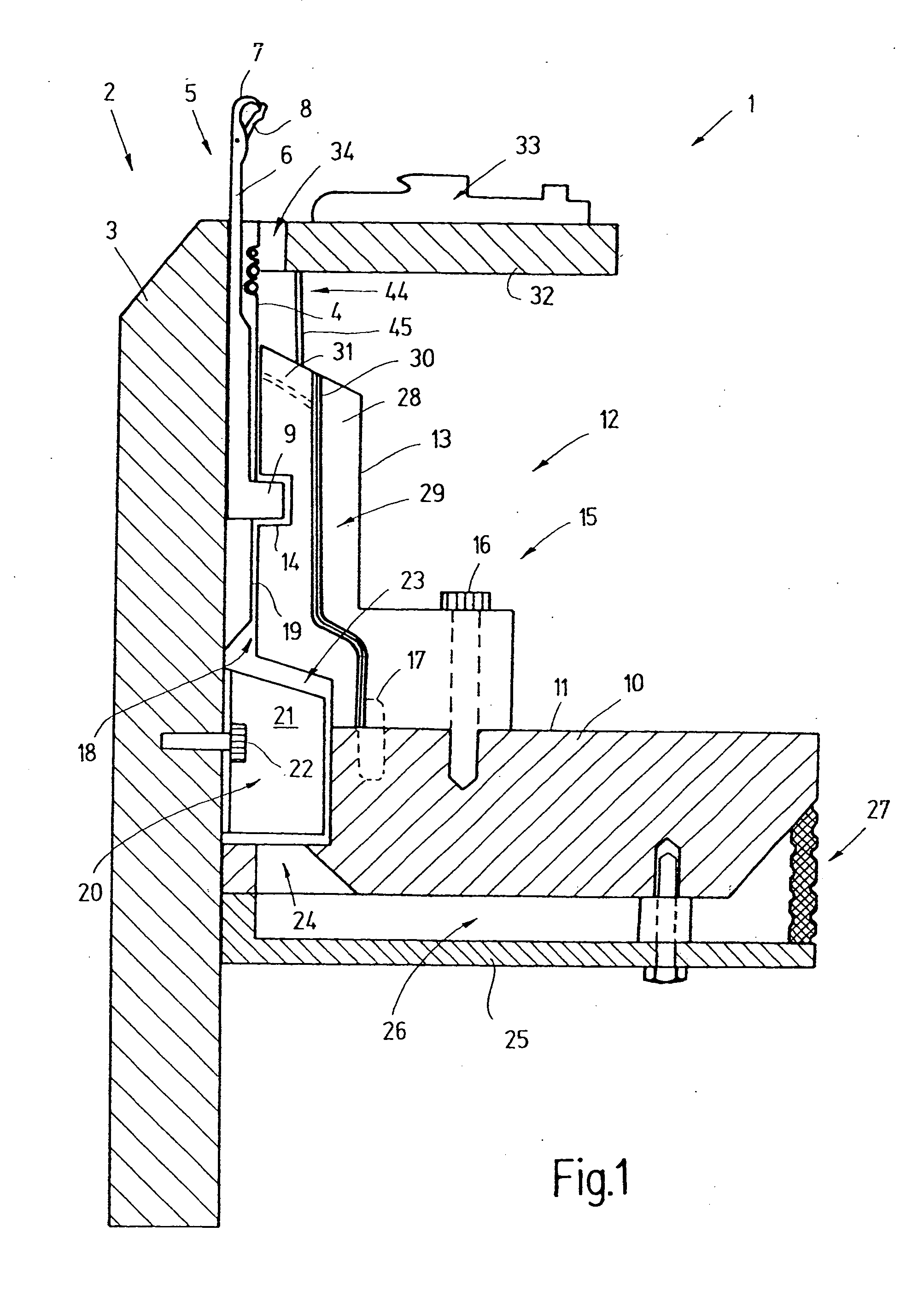

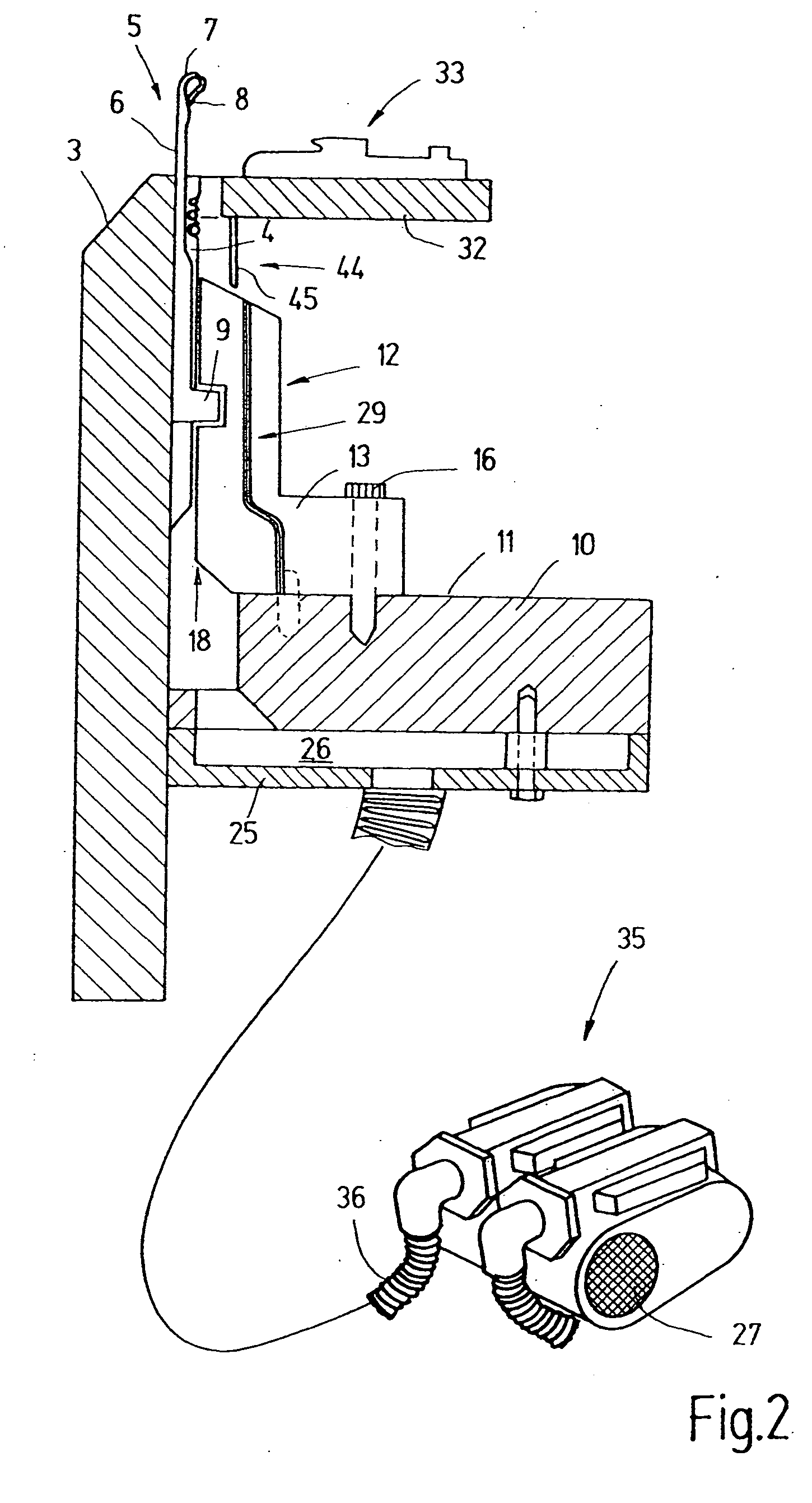

[0025] A knitting machine is illustrated in FIG. 1 with the exemplary embodiment of a circular knitting machine. Its needle bed 2 takes the form of a knitting cylinder 3, provided on its outside with vertical needle slots 4, meaning these extend parallel to its rotational axis. Knitting tools 5 are arranged inside the needle slots 4, e.g. in the form of the latch-type needles 6 shown herein, which can be displaced in longitudinal direction of the respective needle slot 4. The latch needle 6 is provided on one end with a hook 7 that projects from the needle slot 4 and comprises a latch 8, positioned pivoting. The shaft of the latch needle 6 extends inside the needle slot 4 and has a butt 9, which functions to drive the latch needle 6.

[0026] While the knitting cylinder 3 rotates during the operation, a ring-shaped cam base plate 10 that encloses the cylinder from the outside remains stationary. The cam base plate 10 is provided with a cam assembly 12 on its substantially flat surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com