Synthetic resin container

a technology of synthetic resin and container, which is applied in the direction of rigid containers, transportation and packaging, tray containers, etc., can solve the problems of degrading commercial value, and achieve the effects of reducing the burden of classification work, reducing the cost of materials, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

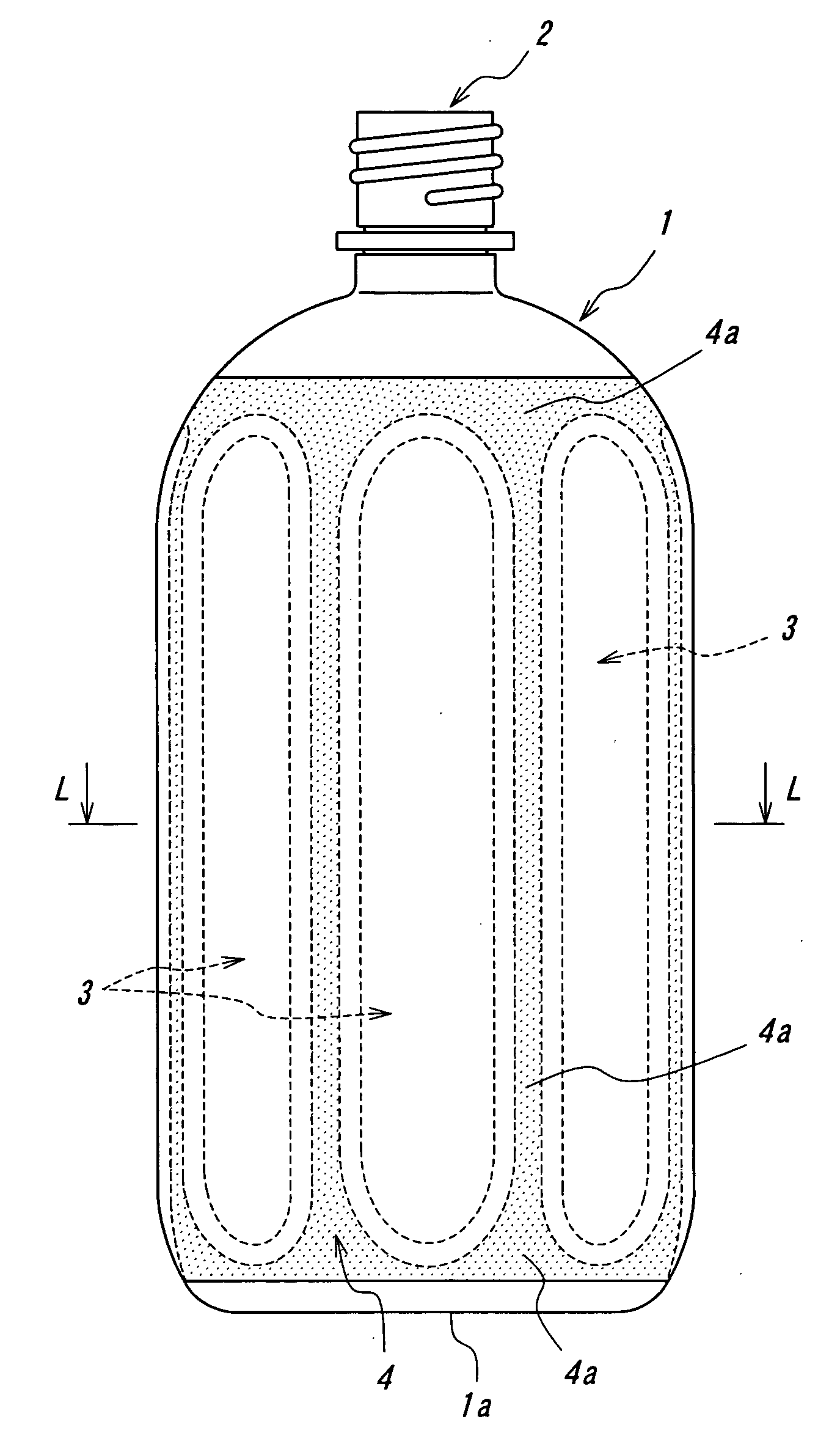

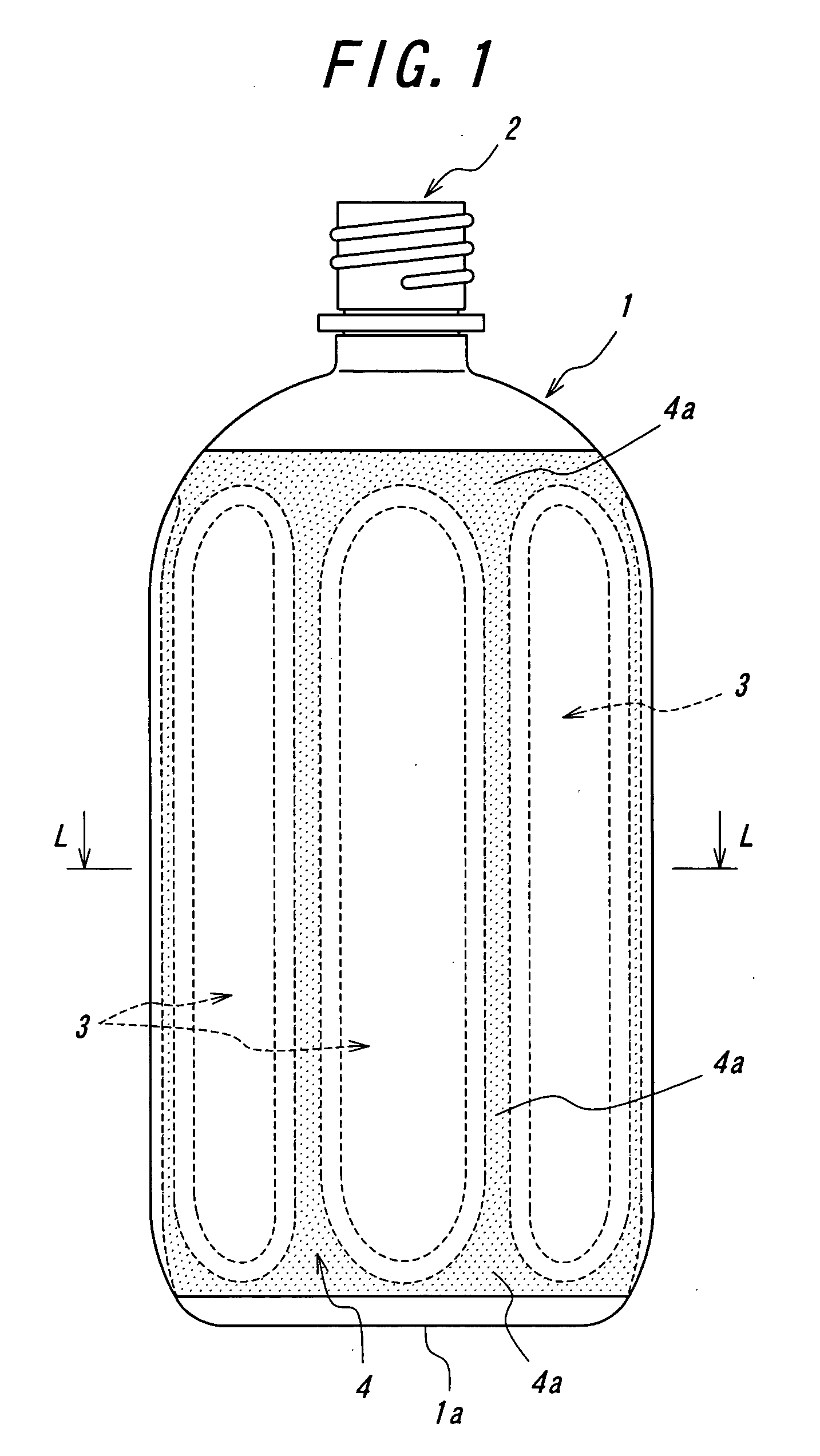

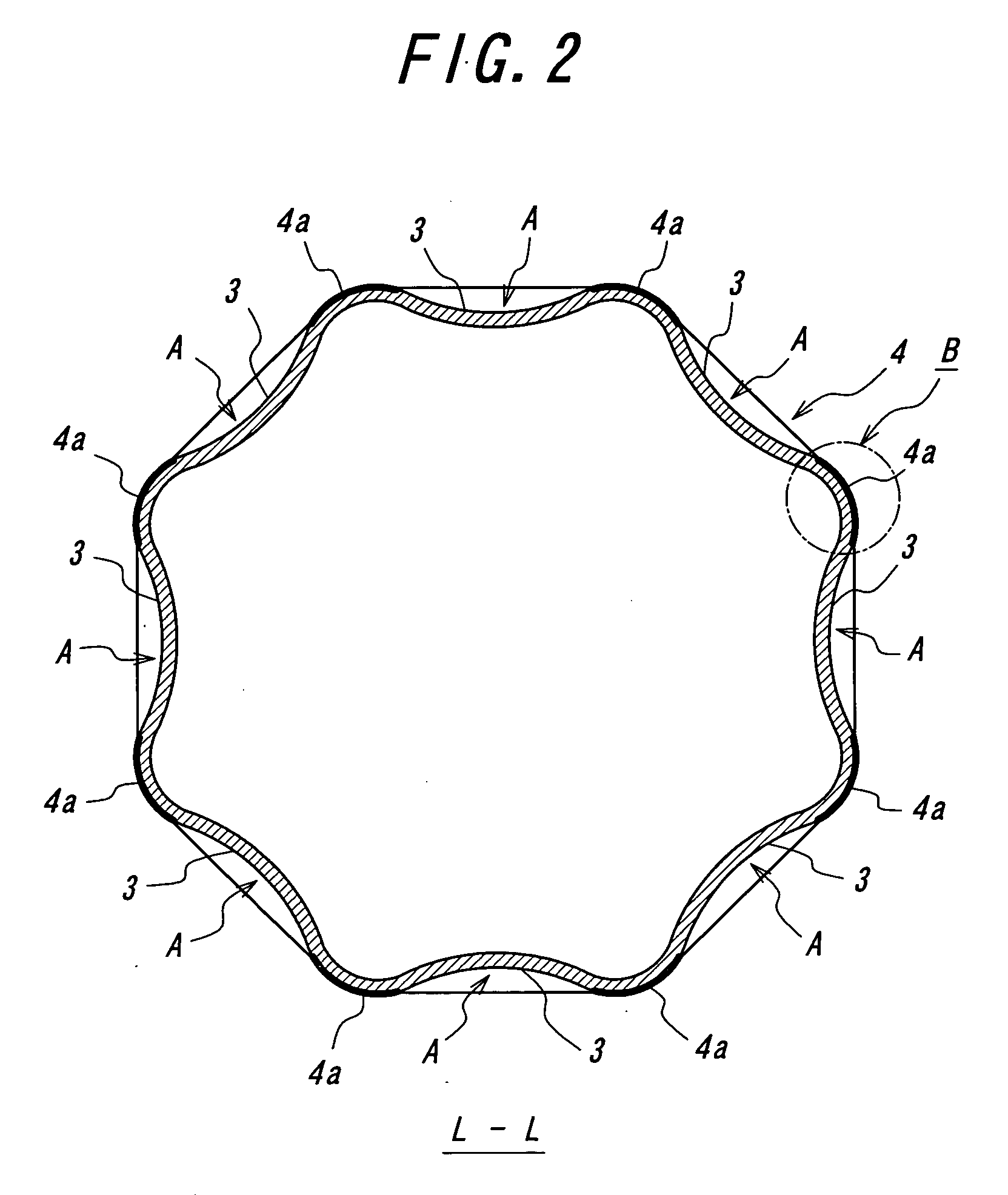

[0036] In order to demonstrate functional advantages of the present invention, there have been produced samples of container of substantially circular cross-section, exhibiting an appearance substantially as shown in FIG. 1. Each sample container has a capacity of 500 milliliters, and is formed with sectioned recesses in the main body portion. These sample containers were produced by biaxial stretch blow molding process using 21 grams of PET resin. Then, the sample container was applied with a label of essentially the same kind of resin as the container (i.e., a heat-shrinkable label applied with a heat-sensitive glue or adhesive agent for the inventive example 1, and a non-adhesive type heat-shrinkable label for the inventive example 2, both having a base layer comprising PET and a thickness of 40 μm). After the label has been applied to the container, the label has been subjected to shrinkage by steam. For there sample containers, the buckling strength, the rigidity of the main bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com