Robot system and method for cathode stripping in electrometallurgical and industrial processes

a robotic system and industrial technology, applied in the field of robotic technology, can solve the problems of high physical demand, harsh environmental conditions, and insufficient separation process, and achieve the effects of avoiding re-separation, avoiding re-separation, and avoiding re-separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

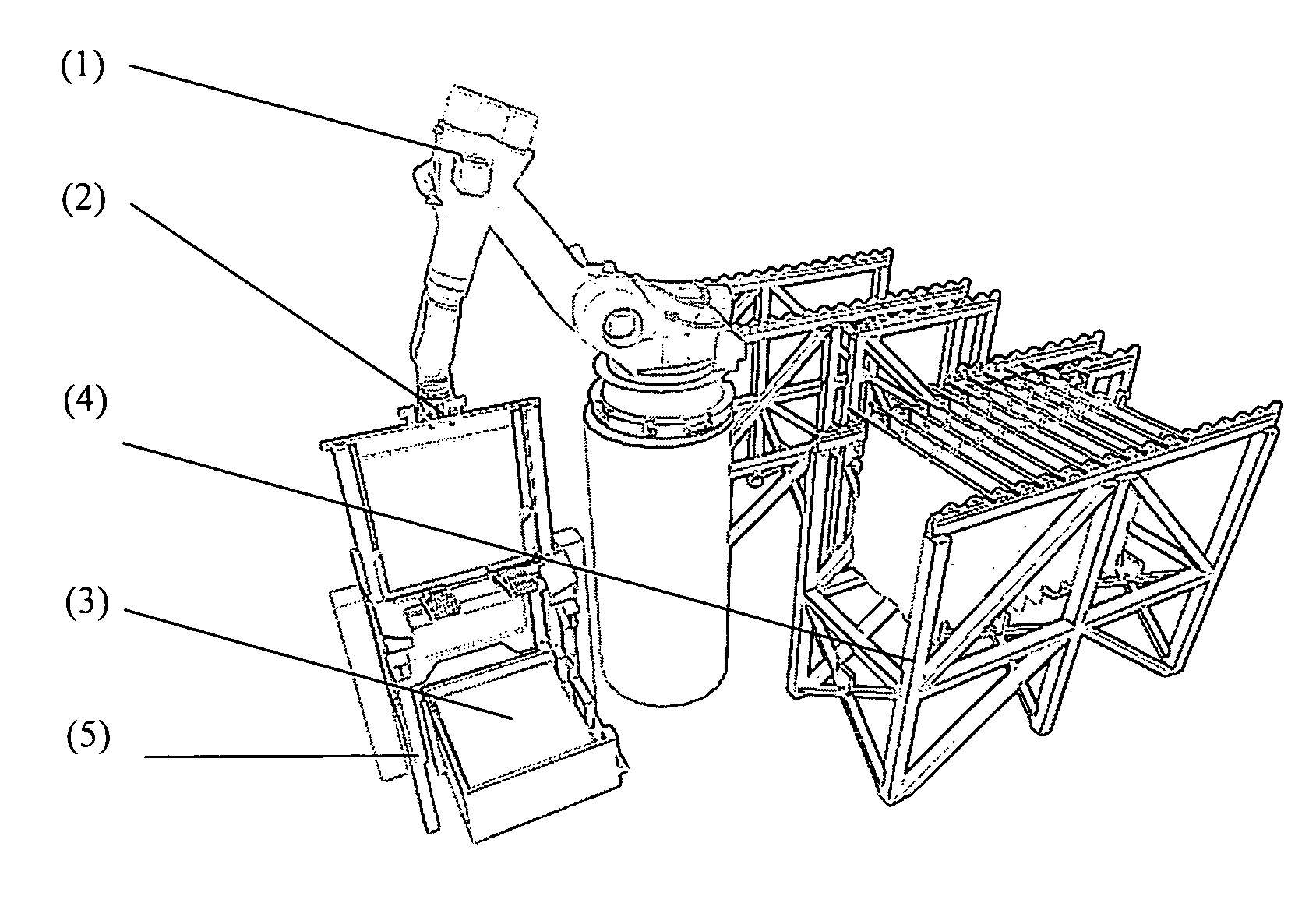

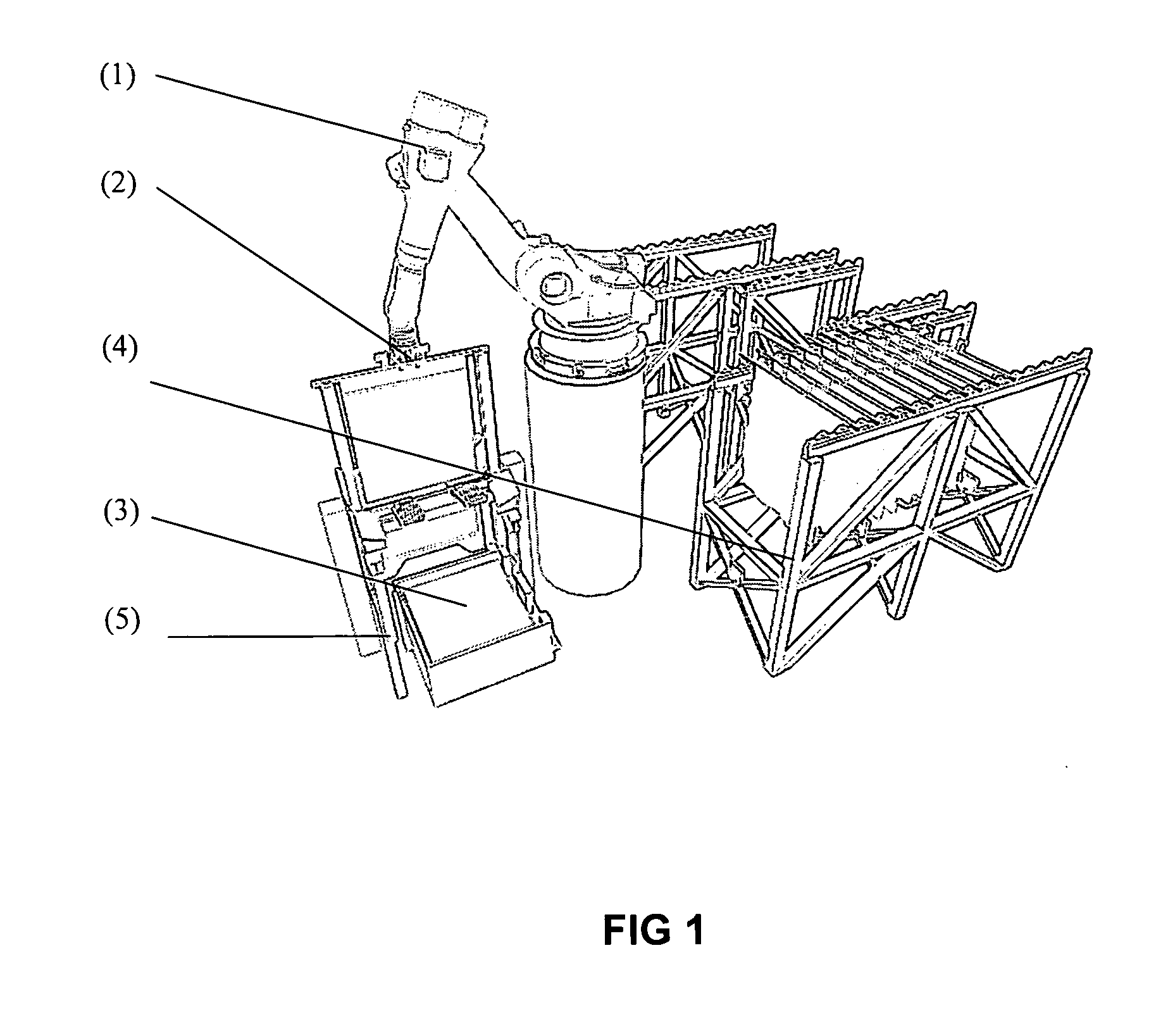

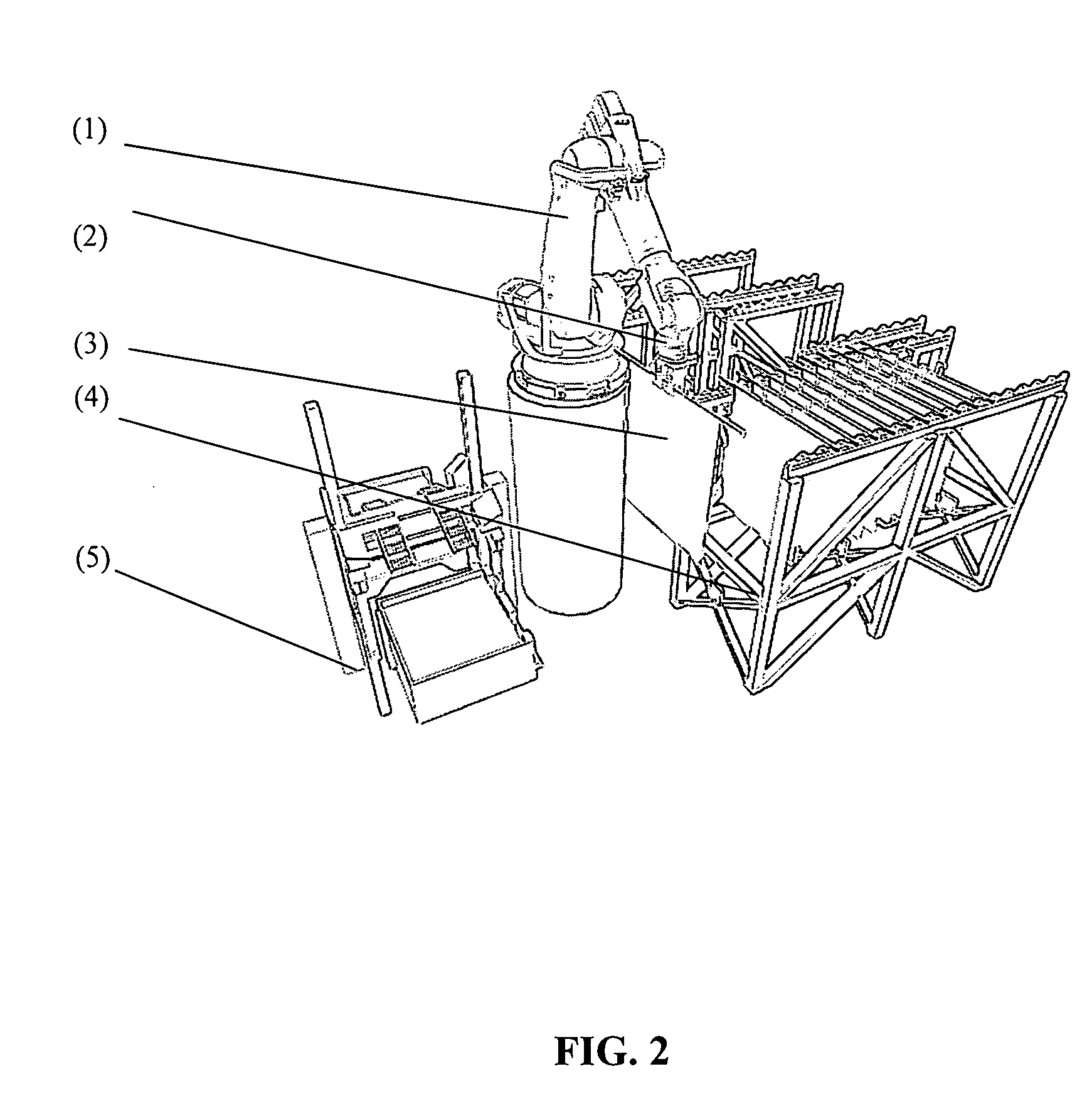

[0028] This invention relates to a new robot system for cathode stripping, which is carried out automatically through anthropomorphous robotic arms of at least 5 degrees of freedom, which are installed at one side of the stripping station.

[0029] With reference to FIG. 1, FIG. 2, and FIG. 3, the robot system is composed mainly of one robotic manipulator (1) of at least 5 degrees of freedom, provided with a communication, acquisition and control system, and a gripping mechanism (2) to allow to take one cathode (3), from a feeding rack (4) located at one of its sides, and moves it through a defined path to the stripping machine (5), where synchronized with the carousel it will carry out the cathode stripping process from the base plate in a sequential and programmed way through successive operations of hammering, bending and separation.

[0030] The robotic manipulator (1) takes the base plate moves it to the unloading rack, while the cathode (3) is stored in pallet for the subsequent m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com