PE bottle detecting and sorting method based on machine vision

A technology of machine vision and defect detection, which is applied in the field of industrial robots and machine vision, can solve the problems of low precision and low work efficiency, and achieve the effects of good accuracy, high production efficiency, high accuracy rate and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

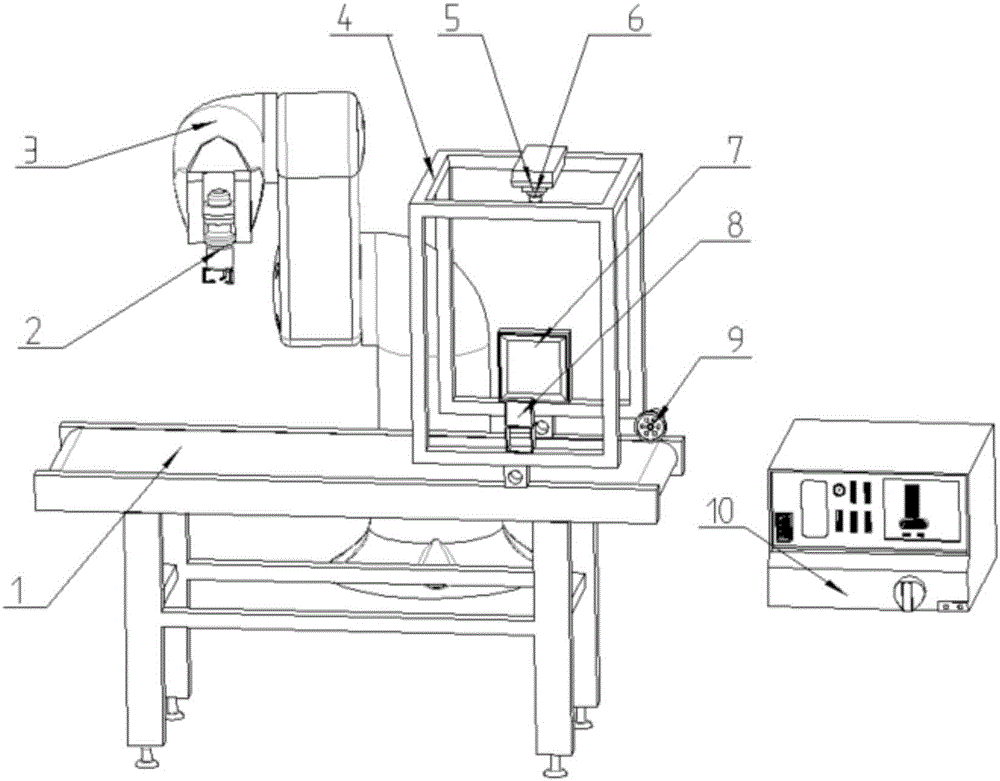

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

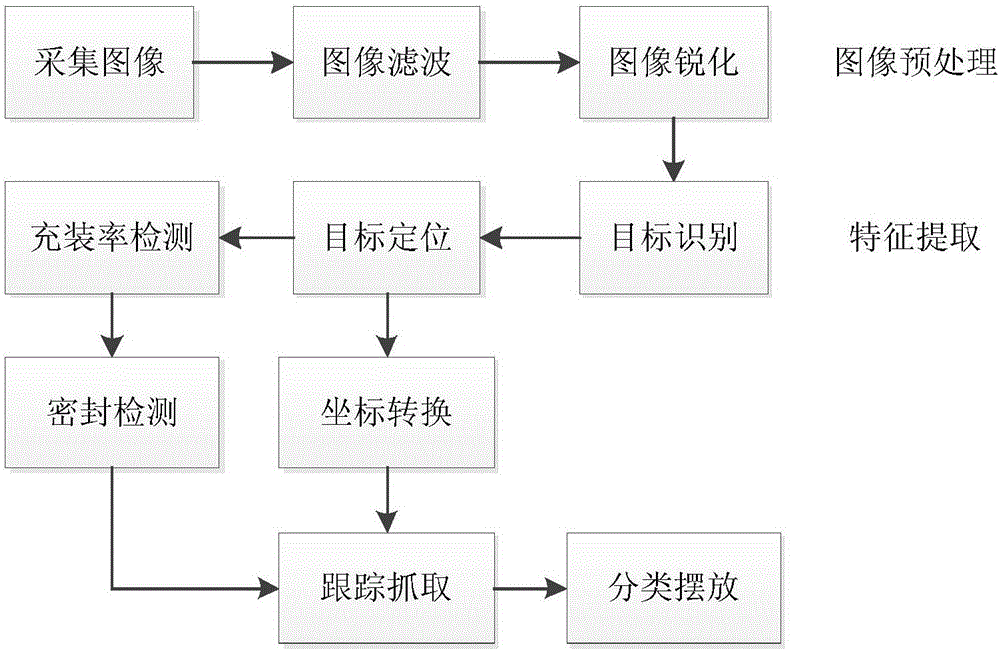

[0028] refer to figure 1 with figure 2 , a kind of PE bottle detection and sorting method based on machine vision, described method comprises the steps:

[0029] (1) PE bottle image acquisition;

[0030] (2) PE bottle image preprocessing: filter and sharpen the collected images;

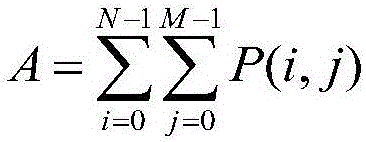

[0031] (3) Target positioning and recognition: Use the matching method based on the contour circumference to match and recognize the PE bottle image, and use the method based on the least squares method to fit the ellipse to complete the detection of the centroid position;

[0032] (4) Defect detection: using the equal circle method and completing the detection of defects at the mouth of PE bottles;

[0033] (5) Tracking and grabbing: According to the feedback position information, calculate the position of the online PE bottle in the Cartesian coordinate system to complete the online gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com