Motorized mount for electronic display

a motorized mount and electronic display technology, applied in the direction of machine supports, building scaffolds, other domestic objects, etc., can solve the problems of occupying floor space, prone to tipping, heavy and difficult for an individual to manage the electronic display on the flat panel, etc., and achieve good structural strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

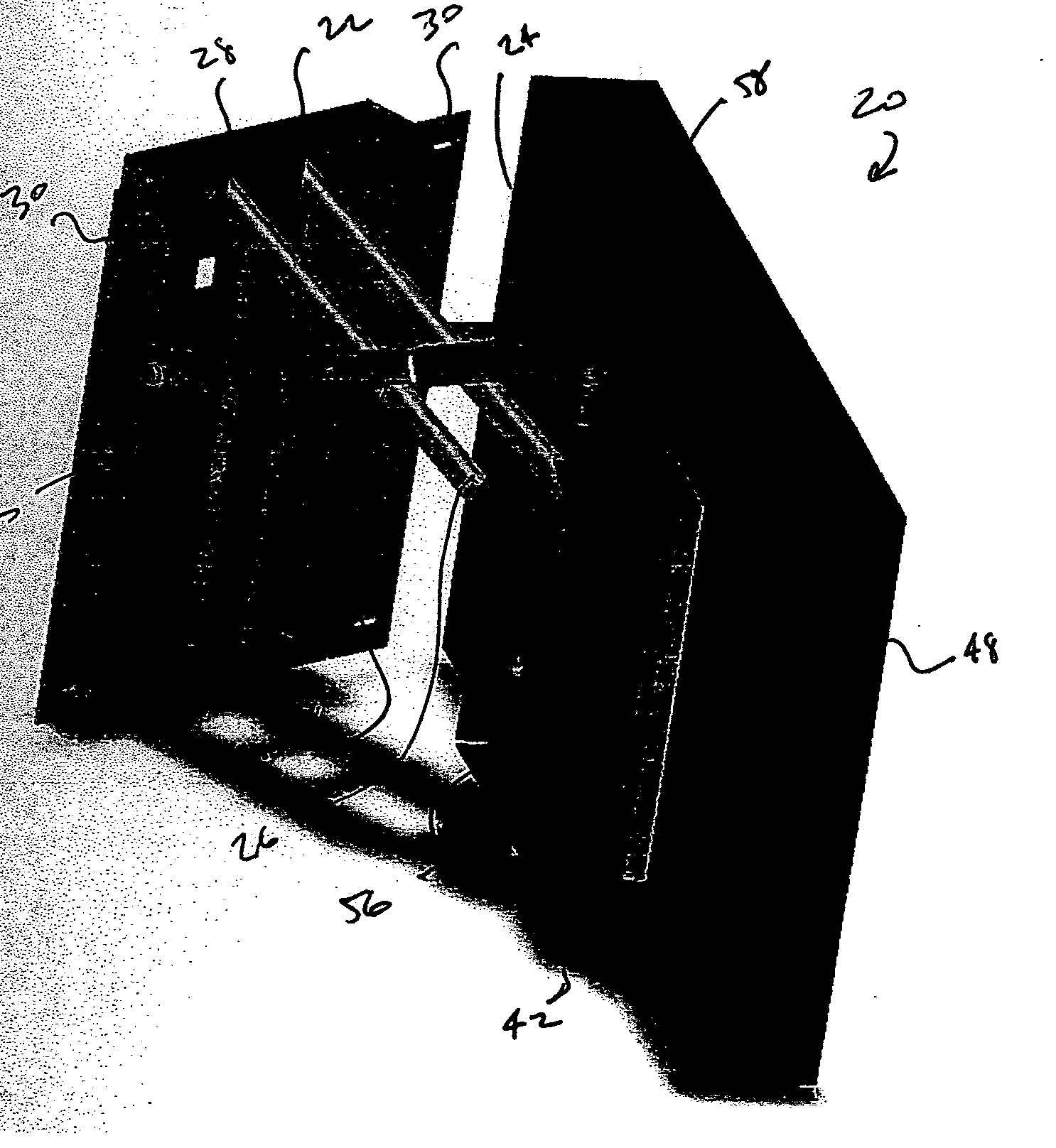

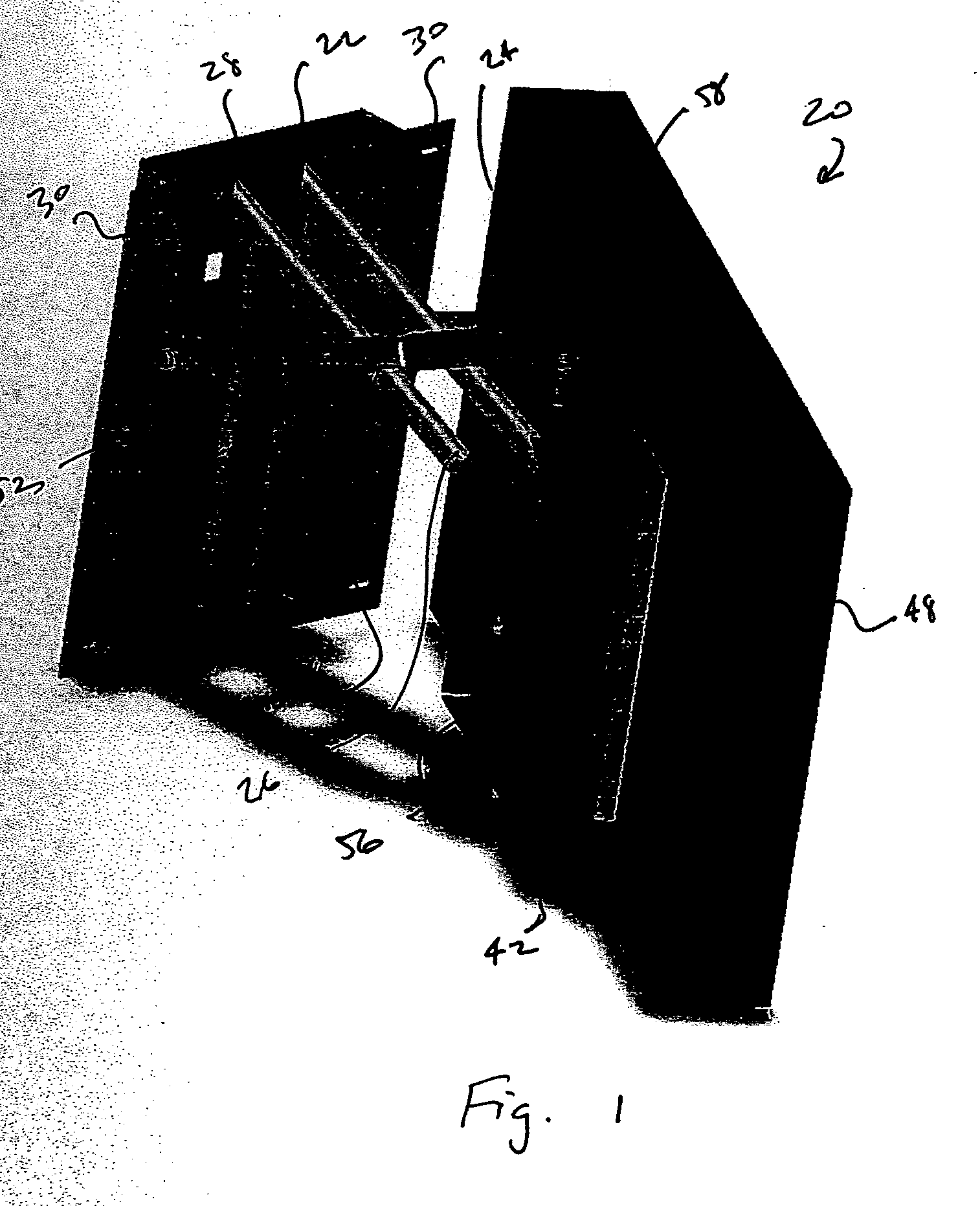

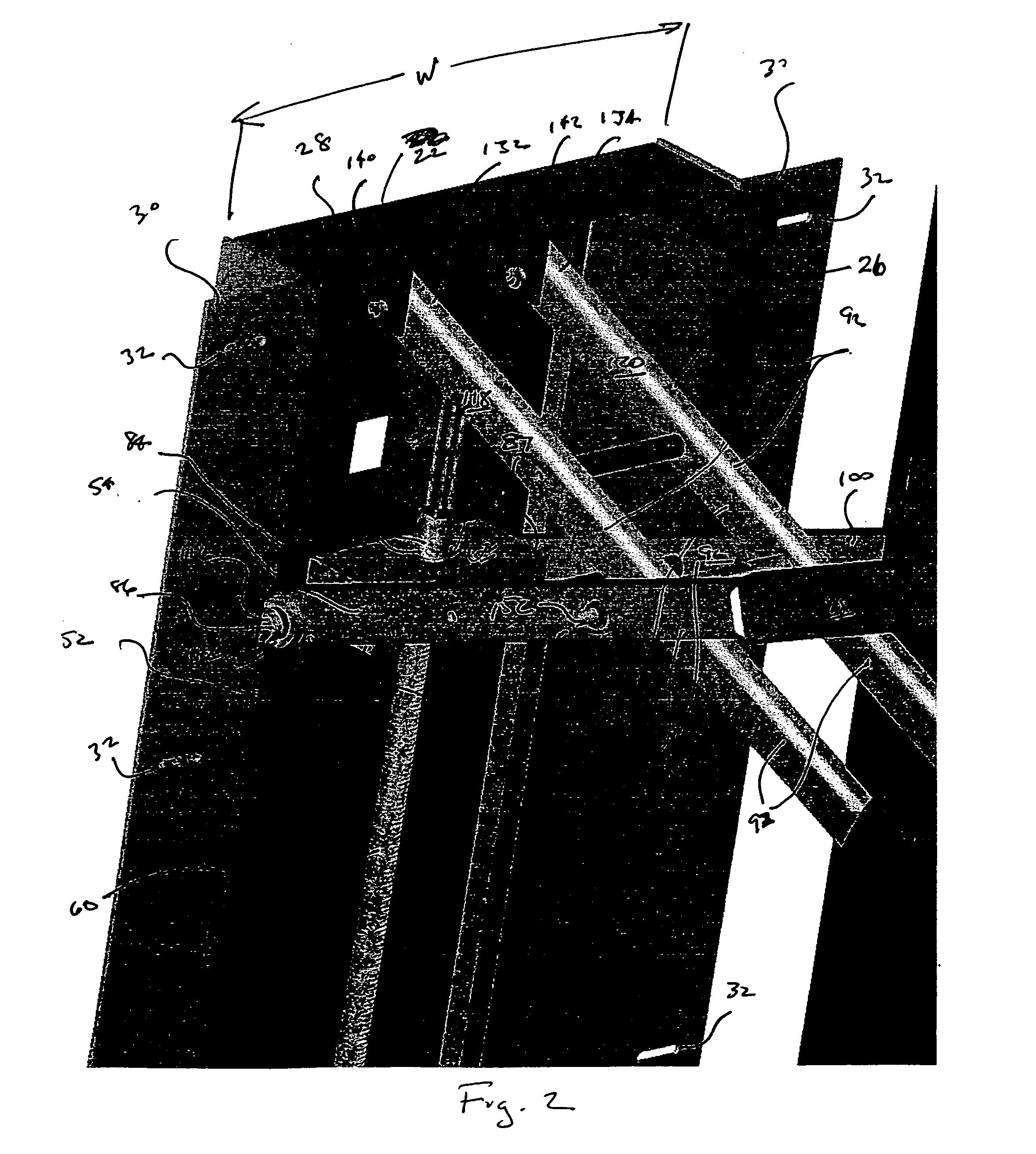

[0022] A motorized mount according to an embodiment of the present invention is depicted generally at 20 in the figures. Motorized mount 20 generally has three major components: wall interface assembly 22, display device interface 24 and positioning assembly 26, as depicted in FIGS. 1 and 6.

[0023] The first component of motorized mount 20 is wall interface assembly 22, shown particularly in FIGS. 2, 3, 7, 11 and 12. Wall interface assembly 22 generally includes housing 28 having a pair of laterally projecting flanges 30. Housing 28 may have a width dimension W (see FIG. 2) defined between the flanges 30 and selected so as to correspond with the spacing between adjacent studs of standard stud spacing in frame wall construction such stud spacing is, for example, 16 inches or 24 inches on center. Each flange 30 may have one or more apertures 32 for receiving fasteners 34 (see FIG. 11) to attach wall interface assembly 22 to studs 36 in a wall 38. Mechanism cover 40 (see FIG. 12) may b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com