Electronic blasting system

a technology of electronic blasting and blasting equipment, which is applied in the direction of make-and-break ignition, lighting and heating equipment, instruments, etc., can solve the problems of invariably using conventional hand-operated control equipment, causing errors, and causing errors in the operation of control equipment in this way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

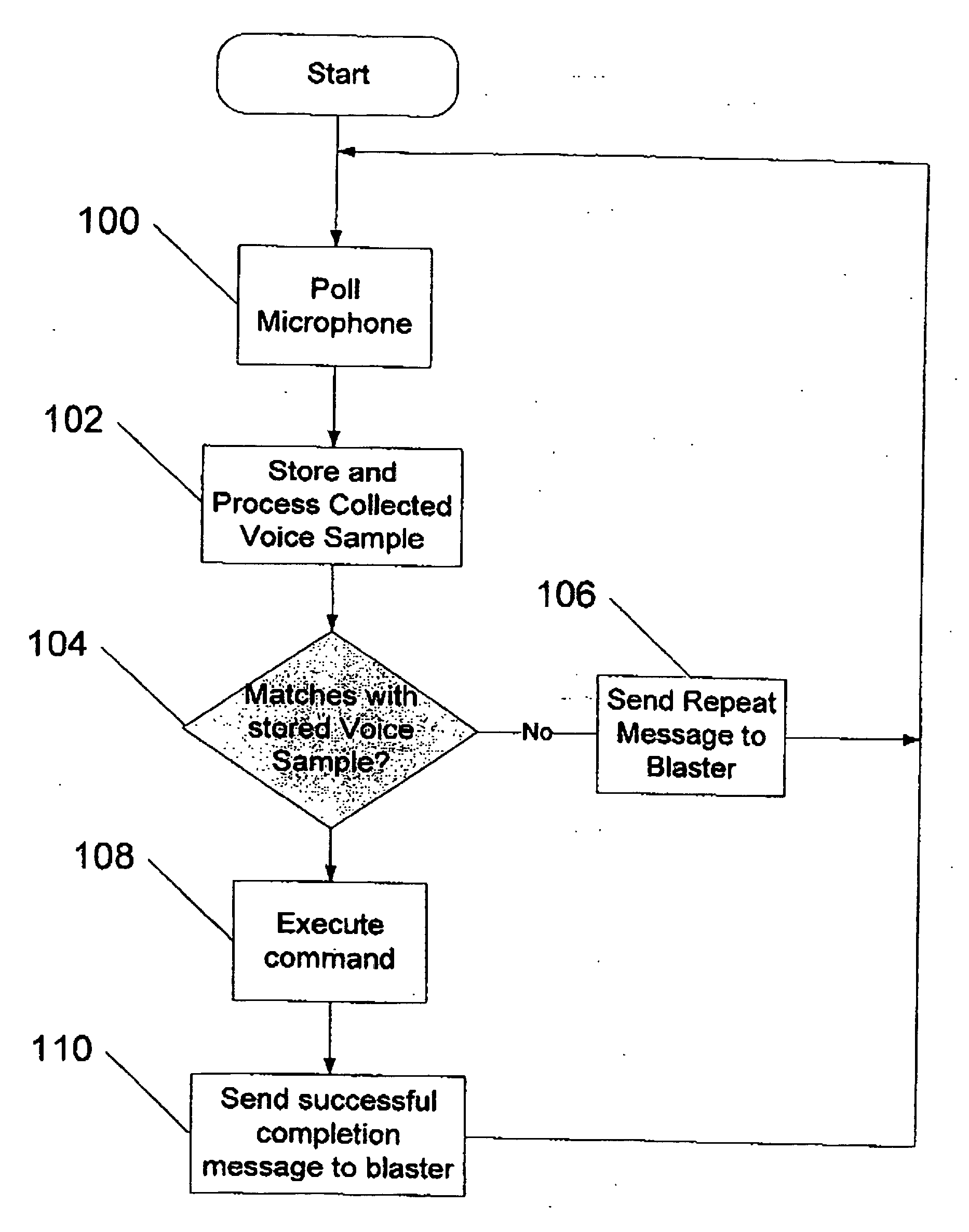

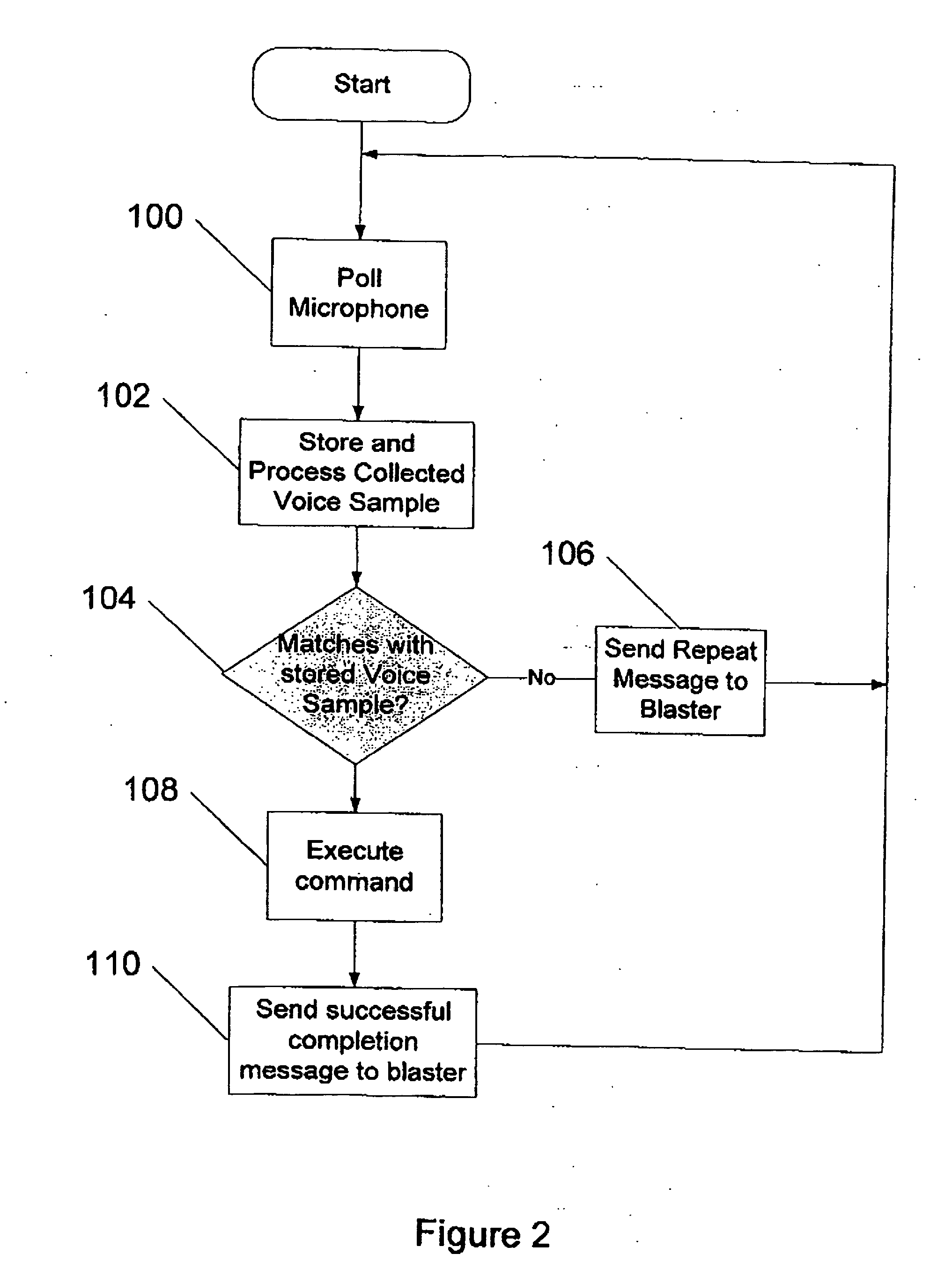

[0015] To enable the blasting machine to be operated under voice control the blast operator may speak into a microphone in communication with the blasting machine. This microphone may be provided on a headset or helmet to be worn by the blast operator. The microphone may be connected to the blasting machine by a wire. Alternatively, wireless technology may be used to relay voice input at the microphone to the blasting machine. In this case conventional wireless technology protocols and componentry may be used, such as Bluetooth™. Depending upon context the blast operator may be in close proximity to the blasting machine during operation of it. Alternatively, the blast operator may operate the blasting machine from a location remote from it. This may be required for safety reasons. In this case voice commands from the blast operator may be relayed to the blasting machine by a hard (wire) connection or using wireless technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com