Flow restricting devices in pumps

a technology of flow restricting device and pump, which is applied in the direction of piston pump, positive displacement liquid engine, liquid fuel engine, etc., can solve problems such as sub-core damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

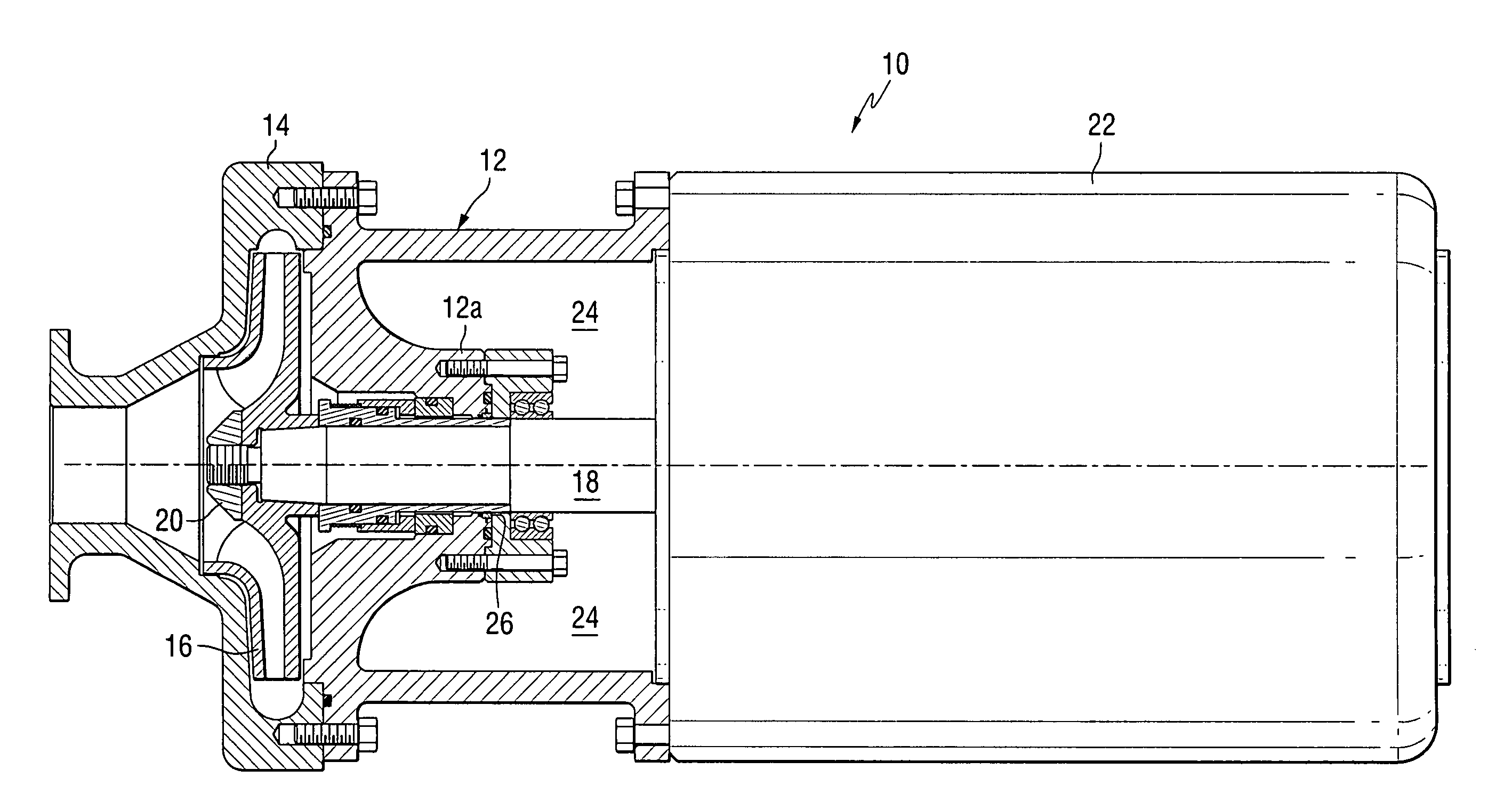

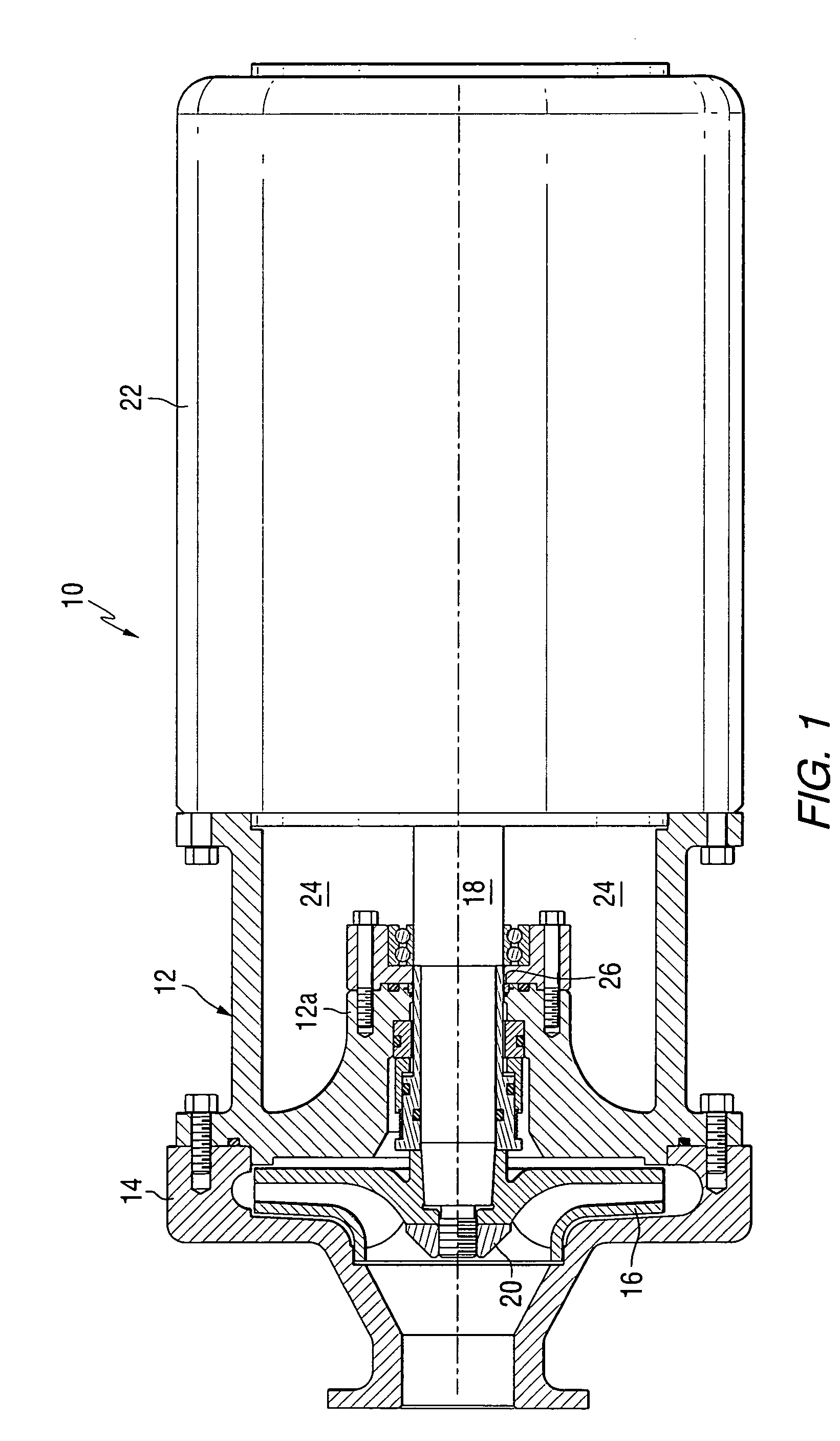

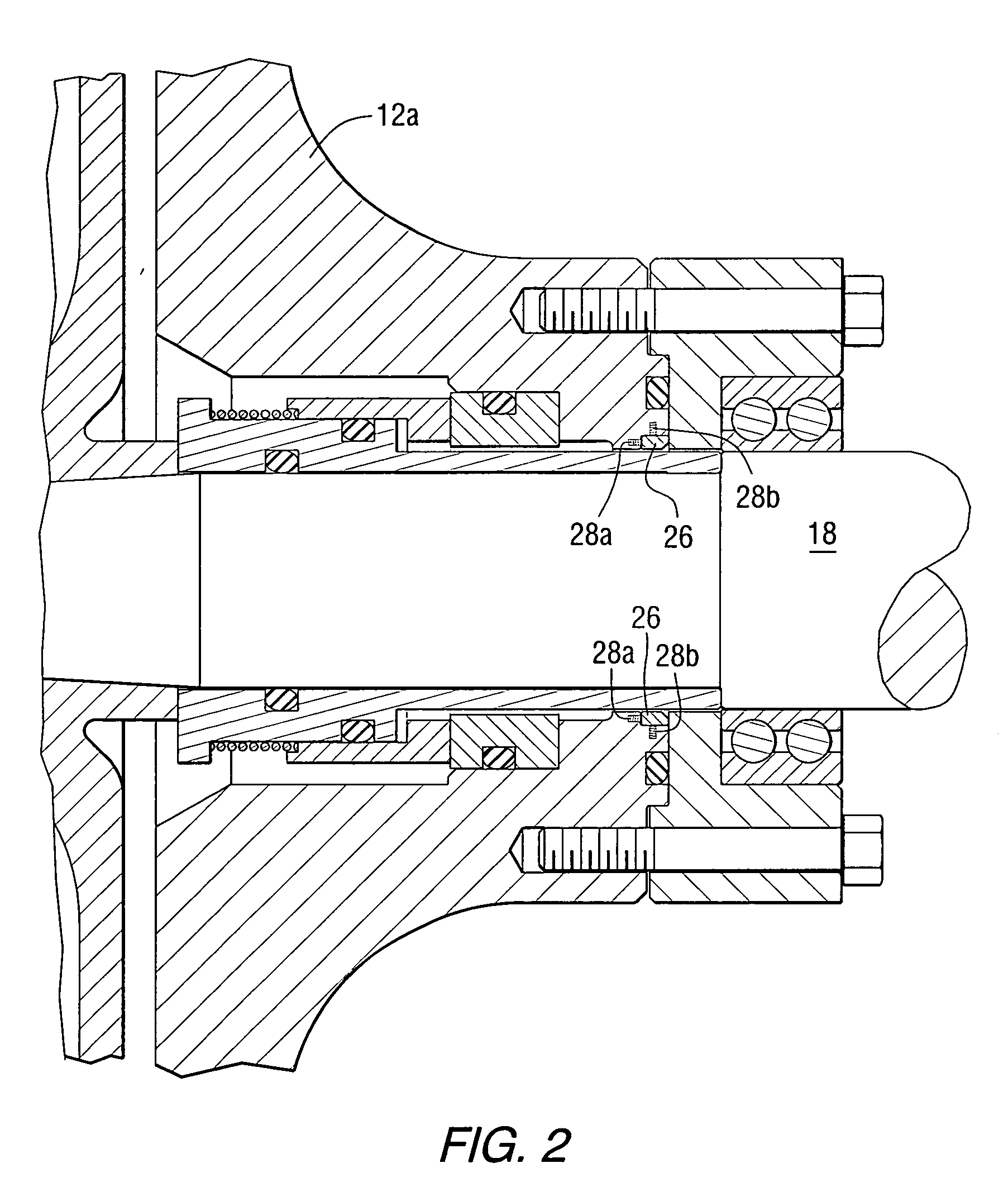

[0031] Referring to FIG. 1, a pump 10 generally includes a main pump housing 12. While, in the embodiment shown, housing 12 forms a large portion of an external housing for pump 10, it retracts inwardly to further form an internal seal housing 12a. An impeller housing 14 is also bolted to the main pump housing 12 and houses an impeller 16. Pump 10 can be representative of a wide variety of rotary pumps, including general centrifugal pumps, nuclear reactor coolant pumps and chemical processing pumps (e.g., as commonly used in the chemical processing industry). Pump 10 may be oriented in any direction appropriate for the application at hand, e.g., a generally horizontal direction or (in the case of a reactor coolant pump) in a generally vertical direction.

[0032] The pump 10 includes a pump shaft 18 extending centrally with respect to the pump housing 12 and being sealingly and rotatably mounted within the seal housing 12a. Pump shaft 18, at one end thereof, is connected to impeller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com