Grease composition and rolling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

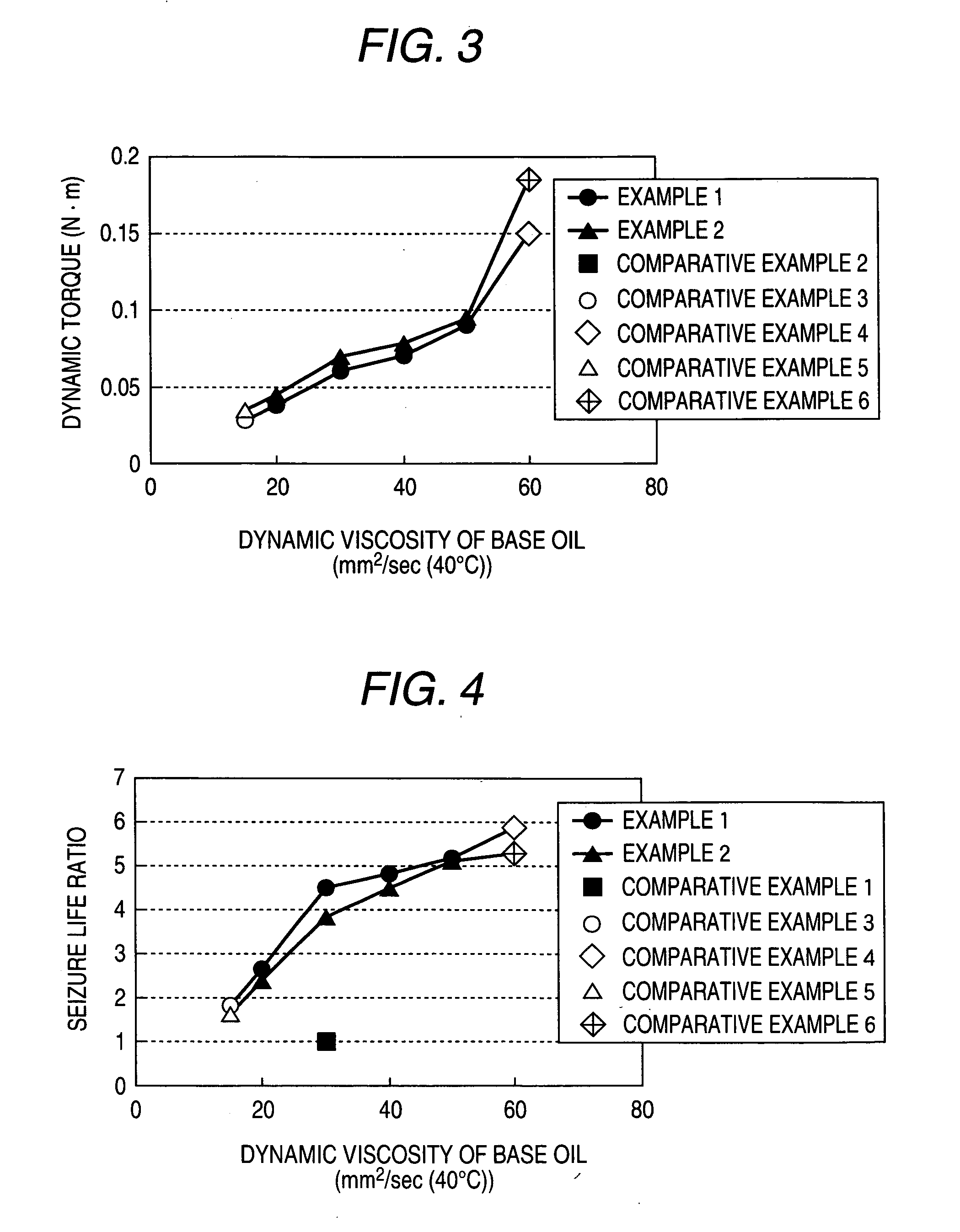

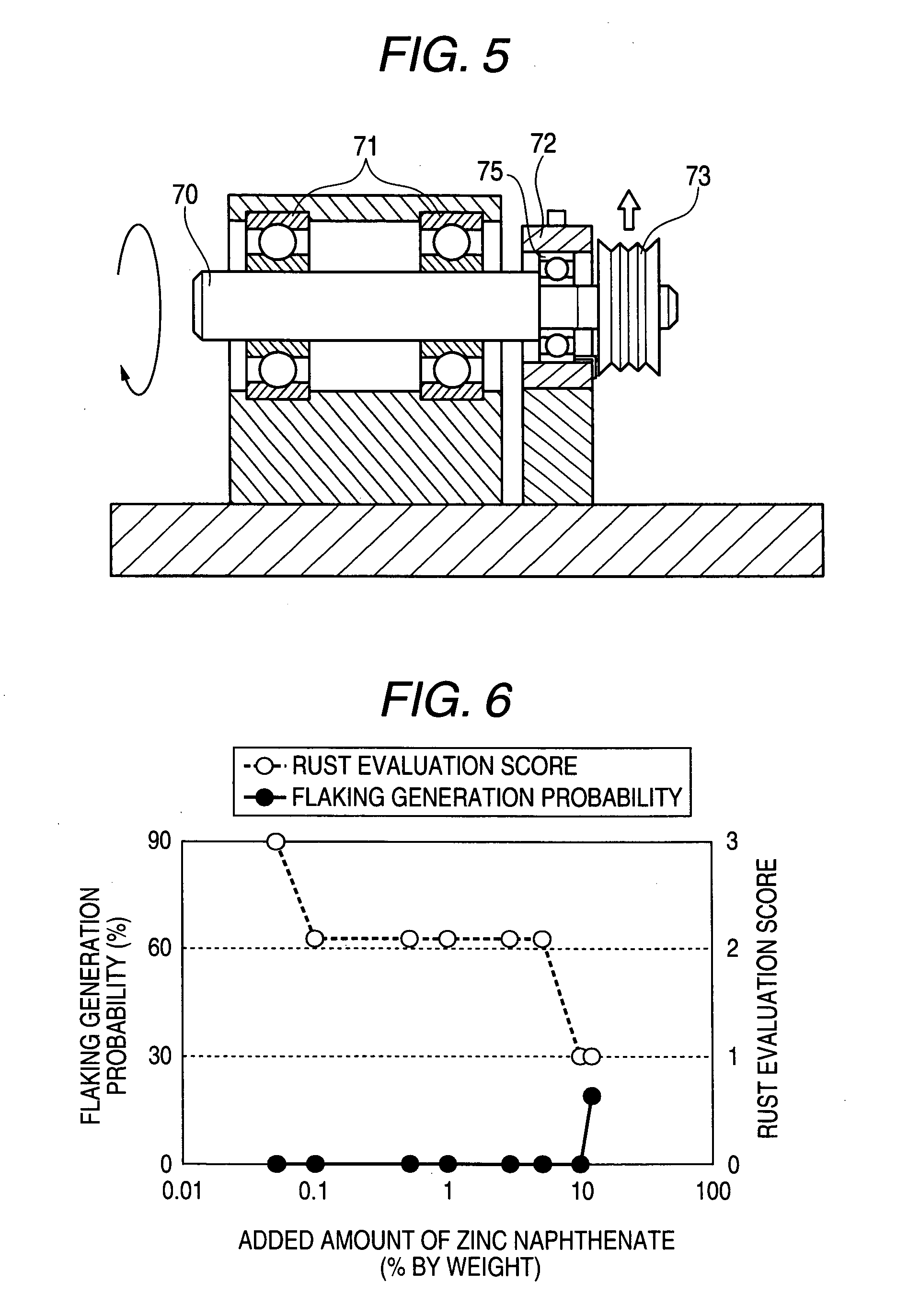

[0034] The following will specifically describe the invention with reference to Examples and Comparative Examples but the invention is not limited thereto. Examples 1 and 2, Comparative Examples 1 to 6

[0035] Test greases were prepared with formulations shown in Table 1. With regard to Examples 1 and 2 and Comparative Examples 2 to 6, a base oil mixed with a diisocyanate was reacted with the same base oil mixed with an amine and the whole was stirred under heating to obtain a semi-solid material, an antirust additive (zinc naphthenate, a succinate ester, barium sulfonate) and / or an organometallic salt (zinc dialkyldithiocarbamate: ZnDTC, zinc dialkyldithiophosphate: ZnDTP), which were already solved in the base oil, were added to the semi-solid material, and the whole was thoroughly stirred and, after gradual cooling, was passed through a roll mill to obtain a grease. With regard to Comparative Example 1, stearic acid and lithium hydroxide were reacted in a base oil to form a lithiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com