Flame-retardant polyester artificial hair

a polyester and flame retardant technology, applied in the field of flame retardant polyester based artificial hair, can solve the problems of high copolymerization amount of copolymerized polyester fiber used for artificial hair, difficult to obtain human hair, insufficient heat resistance, etc., and achieve excellent spinning properties, reduce mechanical strength, and increase melt viscosity

Inactive Publication Date: 2007-08-09

KANEKA CORP

View PDF8 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

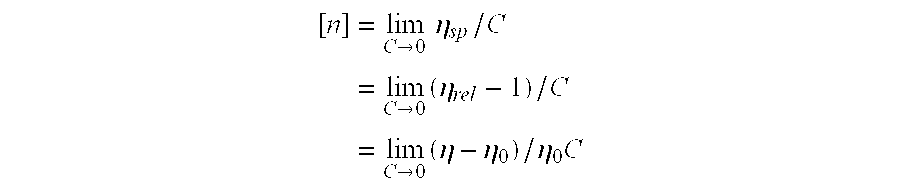

[0041] The composition of the present invention obtained by melt kneading the components (A), (B) and (C) can have a excellent spinning property by controlling the amount of component (C) and adjusting the intrinsic viscosity to 0.5 to 1.4. The composition has an intrinsic viscosity of preferably 0.5 to 1.4, and more preferably 0.6 to 1.2. If the intrinsic viscosity is less than 0.5, the resulting fiber tends to have reduced mechanical strength. If more than 1.4, the melt viscosity is increased as the molecular weight is increased, and thus the fiber tends to be melt spun only with difficulty, and to have a non-uniform size.

[0042] The flame retardant polyester composition used in the present invention can be produced by, for example, dry blending the components (A), (B) and (C) in advance and then melt kneading the components in various conventional kneading machines. Examples of the kneading machines include a single-screw extruder, twin-screw extruder, roll, Banbury mixer and kneader. Of these, a twin-screw extruder is preferable in terms of adjustment of the kneading degree and convenience of operation.

[0043] The composition for the present invention can be obtained by, for example, melt-kneading at a barrel temperature of 260 to 300° C., a discharge mount of 50 to 150 kg/hr, and a screw rotational speed of 150 to 200 rpm with a twin screw extruder having a screw diameter of 45 mm, taking up a strand out of dies, and after cooling with water, pelletizing the strand with a strand cutter.

[0044] The flame retardant polyester based artificial hair of the present invention can be produced by melt spinning the above-describ

Problems solved by technology

However, because it is now more difficult to obtain human hair, the use of artificial hair has become more important.

However, they have insufficient heat resistance.

However, since artificial hair is required to highly flame resistant, the copolymer polyester fiber used for artificial hair must have a high copolymerization amount.

This results in a significant decrease in heat resistance of the polyester, and causes other problems which make it difficult to perform melt spinning.

Also, when a flame approaches, the artificial hair does not catch fire and burn, but becomes molten and drips.

However, in the method which involves adding a flame retardant to a polyester fiber, in order to achieve sufficient flame retardance the addition treatment temperature must be as high as 150° C. or more, the addition treatm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Login to View More

Abstract

It is an object of the present invention to provide a polyester based artificial hair which has an excellent spinning processability, maintains fiber properties such as heat resistance, strength and elongation and the like, and has excellent curl holding properties and iron setting properties. A flame retardant polyester based artificial hair which has an excellent spinning processability, maintains fiber properties such as heat resistance, strength and elongation and the like, and has excellent curl holding properties and iron setting properties can be obtained by melt spinning a composition obtained by melt kneading a polyester, a phosphorus containing flame retardant and/or a bromine containing flame retardant and at least one compound selected from the group consisting of a carbodiimide compound, a bisoxazoline compound and an isocyanate compound.

Description

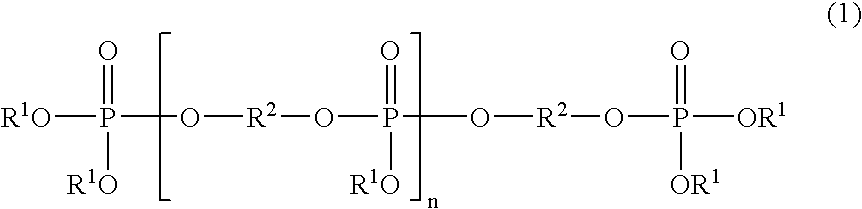

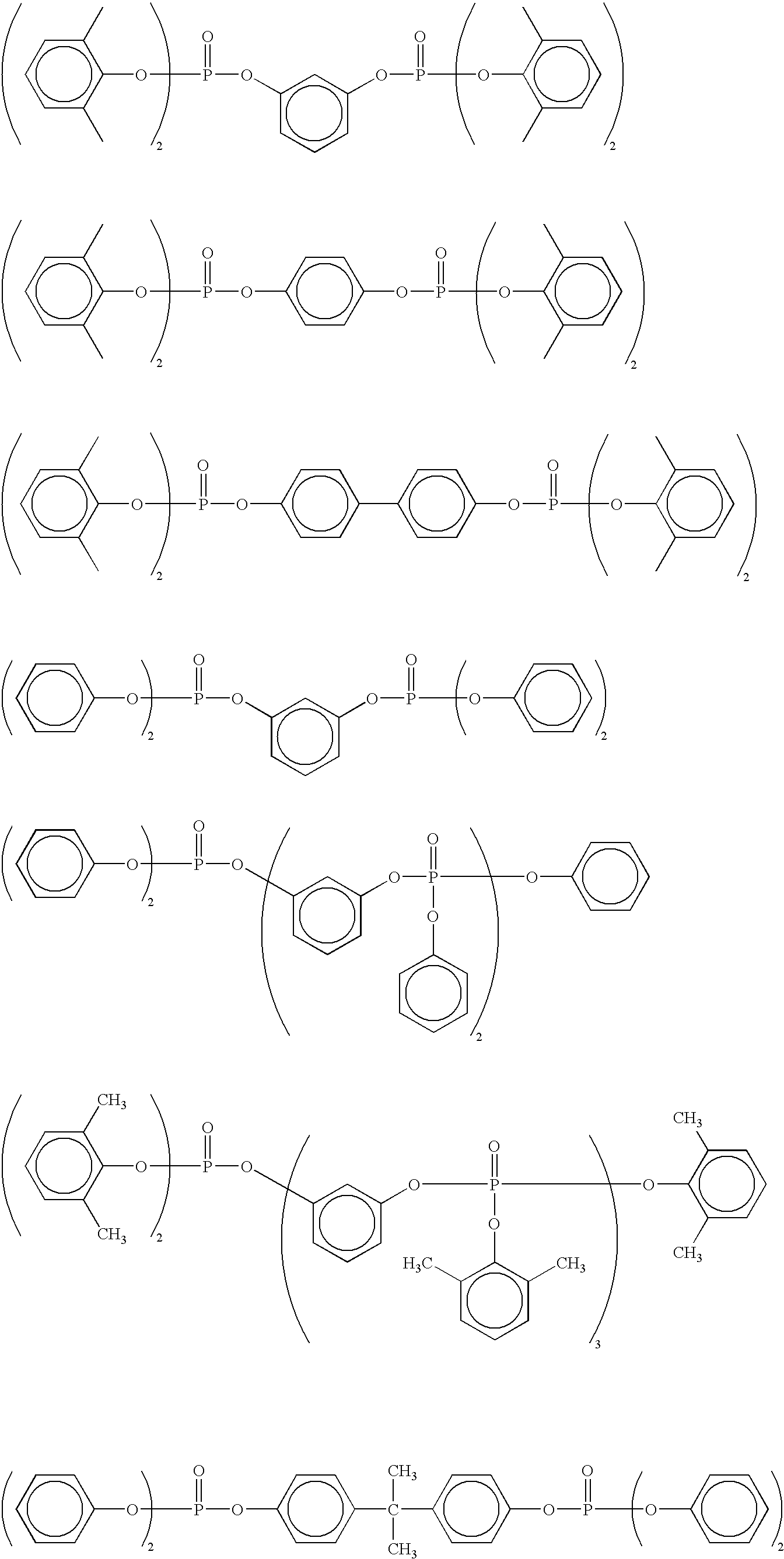

TECHNICAL FIELD [0001] The present invention relates to a flame retardant polyester based artificial hair. The hair is formed from a composition obtained by melt kneading a polyester, a flame-retardant comprising phosphorus and / or a flame-retardant comprising bromine and at least one compound selected from the group consisting of a carbodiimide compound, a bisoxazoline compound and an isocyanate compound. More particularly, the present invention relates to a flame retardant polyester based artificial hair which has excellent spinning processability, maintains fiber properties such as heat resistance, strength and elongation and the like, and also has excellent curl holding properties and iron setting properties. BACKGROUND ART [0002] Fibers made of polyethylene terephthalate or a polyester comprising polyethylene terephthalate as a main component have a high melting point, a high modulus of elasticity, excellent heat resistance and chemical resistance. Thus, they are widely used in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D02G3/00A41G3/00A61L27/00A61L31/06A61L31/14D01F1/07D01F6/92

CPCA41G3/0083A61L31/06A61L31/14Y10T428/2913D01F6/92D01F1/07C08L67/02A41G3/00

Inventor MASUDA, TOSHIYUKI

Owner KANEKA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com