Highly paraffinic, moderately aromatic distillate fuel blend stocks prepared by low pressure hydroprocessing of fischer-tropsch products

a distillate fuel and low pressure technology, applied in the preparation of fuels, oxygen-containing compound preparations, hydroprocessing of distillate fuels, etc., can solve the problems of limiting the use poor seal swell properties of fischer-tropsch distillate fuels, and hydrogen consumption in hydroprocessing of these fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Diesel Fuel Samples

[0110] A Low Temperature Fischer-Tropsch product was generated by reacting synthesis gas over an iron-containing catalyst. The product was separated into a diesel boiling range blend stock (A) and a wax. The diesel blend stock (A) was hydrotreated to remove oxygenates and saturate olefins. The wax was hydrocracked over a sulfided catalyst consisting of amorphous silica-alumina, alumina, tungsten and nickel. A second diesel blend stock (B) was recovered from the effluent of the hydrocracker. The two diesel blend stocks were blended in the proportion of 82% B and 18% A by weight. Properties of the Fischer-Tropsch (FT) diesel fuel blend are shown in Table I.

TABLE IProperties of Fischer-Tropsch Diesel Fuel BlendFischer-ASTM D975TropschTESTSSPECIFICATIONSDiesel BlendAPI GRAVITY, 60° F.40(min.)52.3NITROGEN, NG / UL0.69CETANE INDEX ASTM D61372.3NORMAL / NON-NORMALPARAFFINS WT. %NORMAL PARAFFINS17.24NON NORMAL PARAFFINS82.76DISTILLATION D86, ° F. IBP33310%5...

example 2

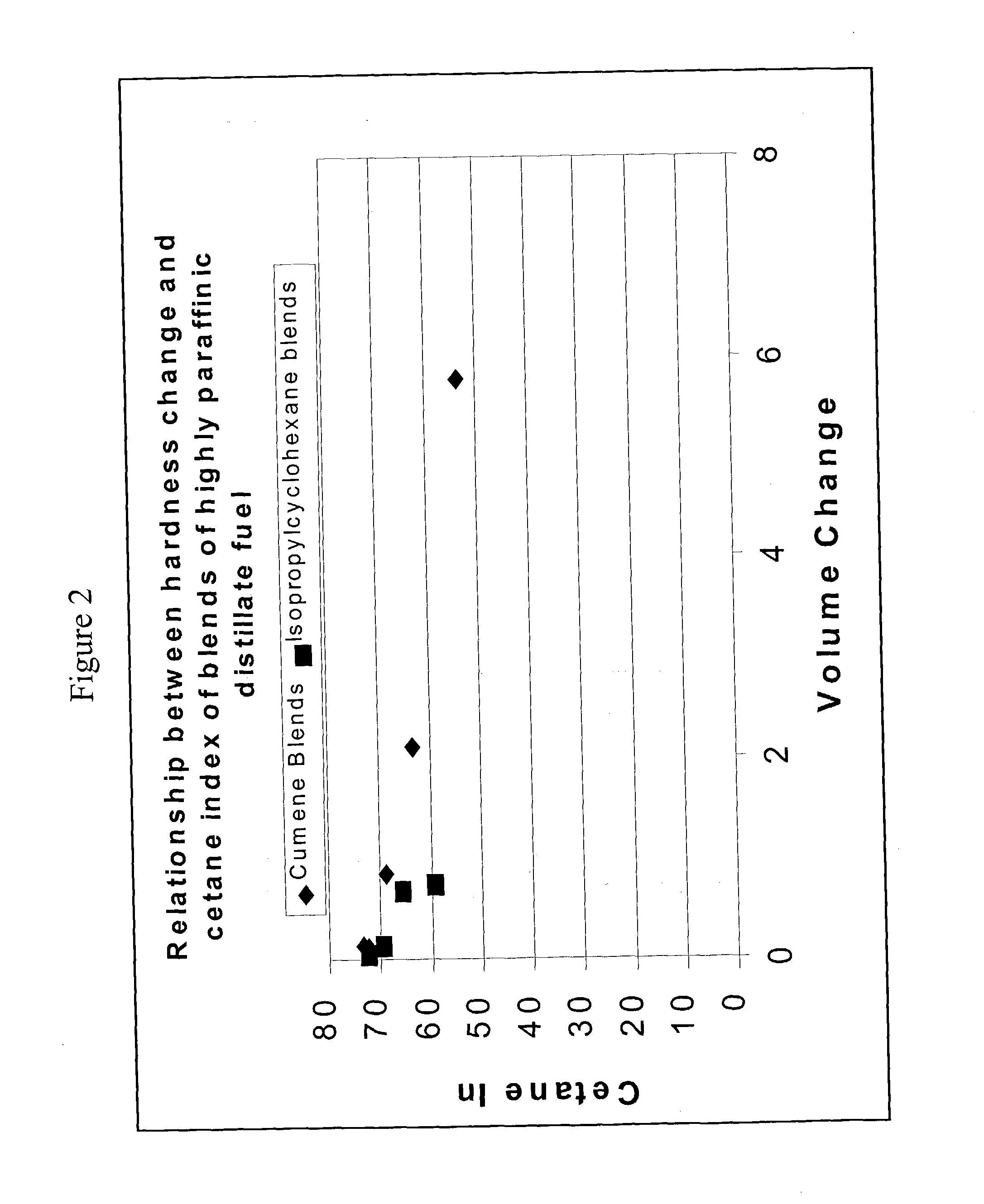

Preparation and Evaluation of Blends of Fischer Tropsch Diesel with Alkylaromatics and Alkylcycloparaffins

[0111] Blends of a light alkylaromatic (cumene) or alkylcycloparaffin (isopropylcyclohexane) with a Fischer Tropsch diesel fuel blend stock were prepared. The improvement in the seal swell and lubricity were determined along with the decline in cetane index. A preference for alkylaromatics or alkylcycloparaffins can be determined by finding which species gives the greatest improvement in seal swell with the least decline in cetane index. The cetane index in these experiments was determined from a D2887 distillation, converted to D86 equivalent, molecular weight and density at 20° C. This method provides an acceptable and reproducible measurement of the cetane index.

The seat swell test followed ASTM D471:

[0112] O-ring type: Buna N O-ring, size 2-214; vendor: McDowell & Co. [0113] Test Temperature: ambient 23+ / −2° C. [0114] Test Duration: 70 hours [0115] Test sample size: 100...

example 3

[0120] A light Fischer-Tropsch wax (Table III) was hydrocracked over a sulfided nickel-tungsten / silica-alumina catalyst LHSV 1 hr−1, 1000 psig, 685° F., and 6.3 MSCF / bbl. At these conditions, conversion below 650° F. was 80.4 weight %. The liquid product was cut at about 350° F. and about 675° F. to give a diesel blend stock fraction. Yields and properties of the diesel blend stock are given in Table IV.

TABLE IIIFEEDSTOCK INSPECTIONS OF LIGHT FT WAXGravity, API42.5Nitrogen, ppm3.2Sim. Dist., LV %, ° F.ST / 5728 / 77110 / 30789 / 8115083970 / 90858 / 88595 / EP898 / 943

[0121]

TABLE IVHYDROCRACKING OF LIGHT FT WAX OVERNi—W—SIO2—AL2O3 AT LHSV 1 hr−1, 685° F.,1000 PSIG, AND 6.3 MSCF / BBLConversion 80.4Yield, Weight %C1-C20.03C3-C45.06C5-180° F.17.77180-350° F.20.85350-650° F.37.51650° F.+19.71C5+95.49350-675° F. PropertiesWeight % of Feed52.9Gravity, API50.7Viscosity, 40° C., cSt2.631Cloud Point, ° C.−26SFC Analysis, Wt %Aromatics0.3Olefins0.8OxygenatesSaturates98.9PNA Aromatics, weight %Not DetectedCe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight % | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

| volume change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com