Large bottle-shaped container having substantially rectangular cross section

a bottle-shaped container and substantially rectangular technology, which is applied in the direction of rigid containers, large containers, packaging, etc., can solve the problems of permanent deformation of the grip, damage to the appearance of the bottle, and the inability of a large bottle to absorb a reduced internal pressure, so as to improve the rigidity of the bottle, and facilitate the container with high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

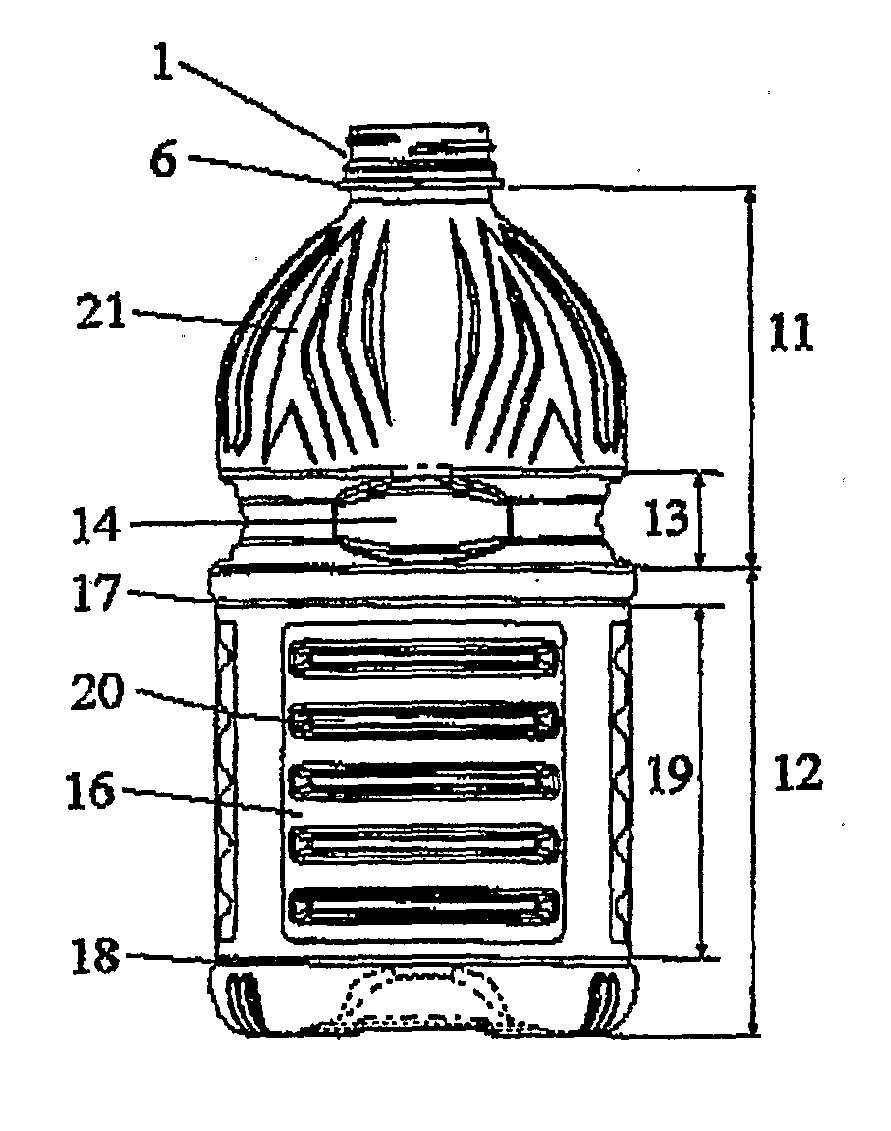

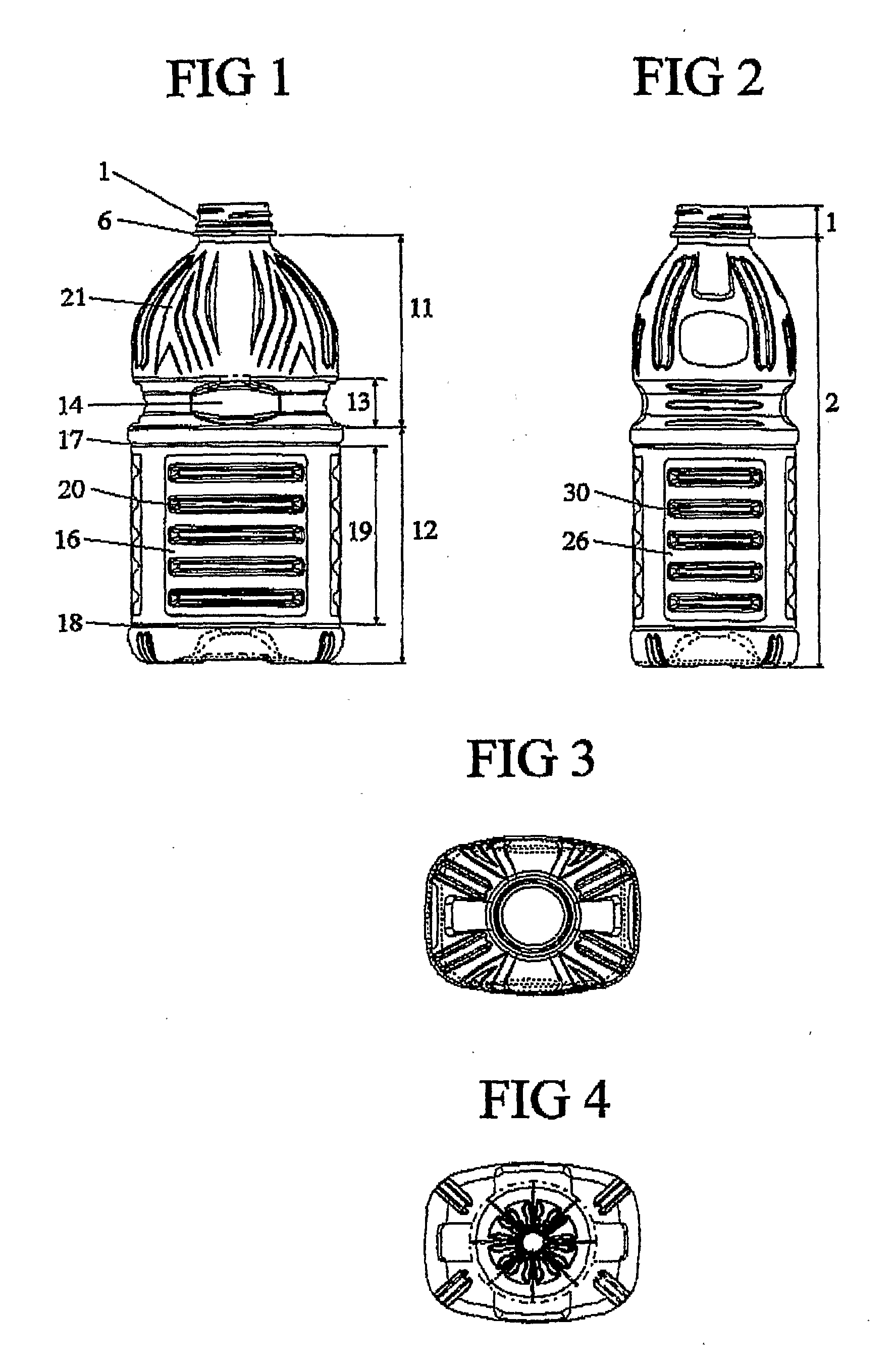

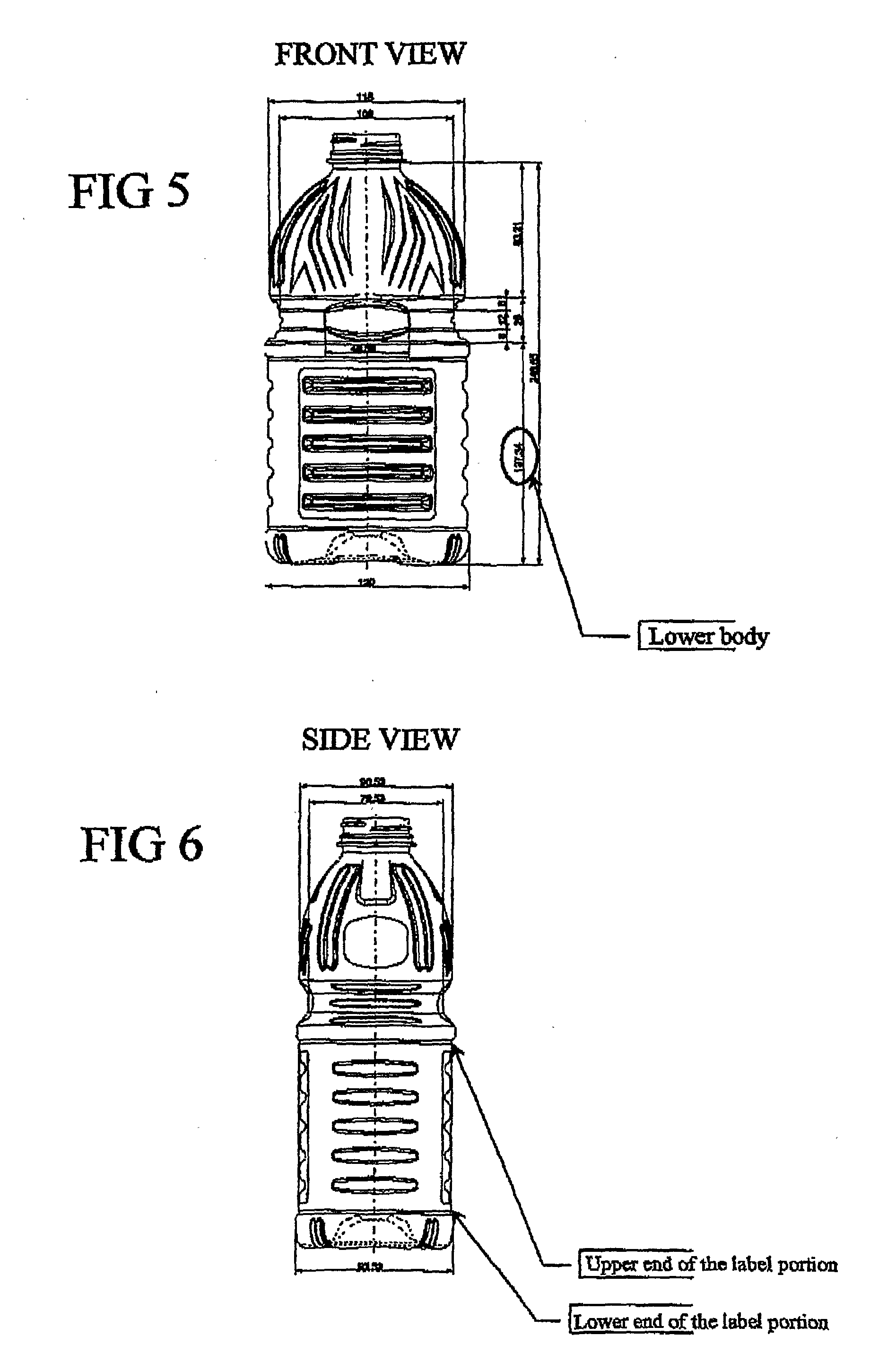

[0034] Now, firstly a container in the first aspect of the present invention will be described by referring to FIGS. 1-6.

[0035]FIGS. 1-6 illustrate a bottle-shaped container according to the invention which is a large 64-ounce bottle having a weight capacity of about 1.8 kg and a volume capacity of about 1.8 liters). While the present invention is not limited to a container having a volume capacity of 1.8 liters, it is particularly effective for a container having a volume capacity not smaller than 1 liter. It is equally effective for a container having a volume capacity of 2 liter or 3 liters. The bottle-shaped container comprises a neck 1 and a body 2. The container is manufactured by using a known synthetic resin material, which may typically be polyethylene terephthalate.

[0036] The body 2 comprises an upper body 11 and a lower body 12. The body 2 shows a substantially rectangular cross section, and hence has longer sides and shorter sides.

[0037] The upper body 11 includes a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com