Method of manufacturing an upper for an article of footwear

a manufacturing method and technology for footwear, applied in the field of uppers for footwear, can solve problems such as irritation points and discomfort areas for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

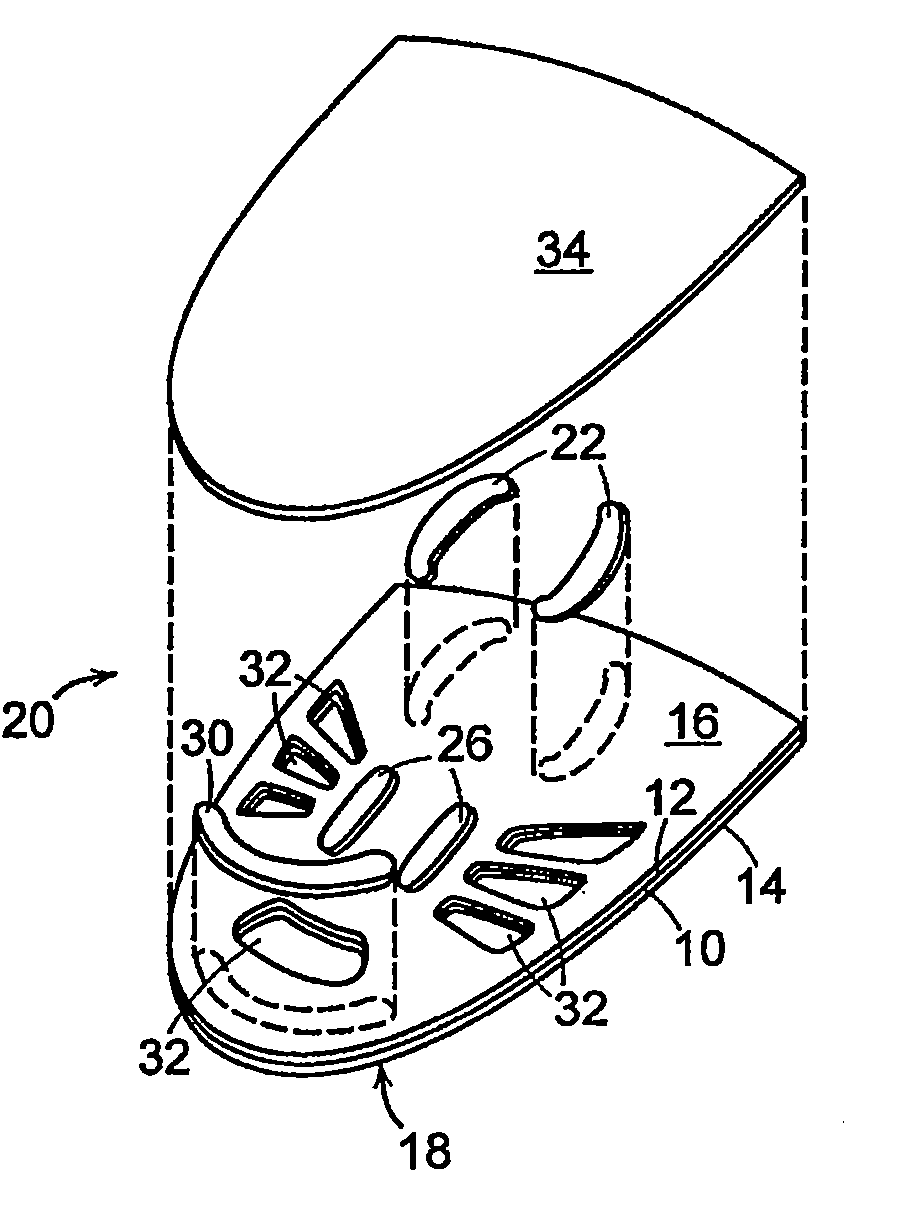

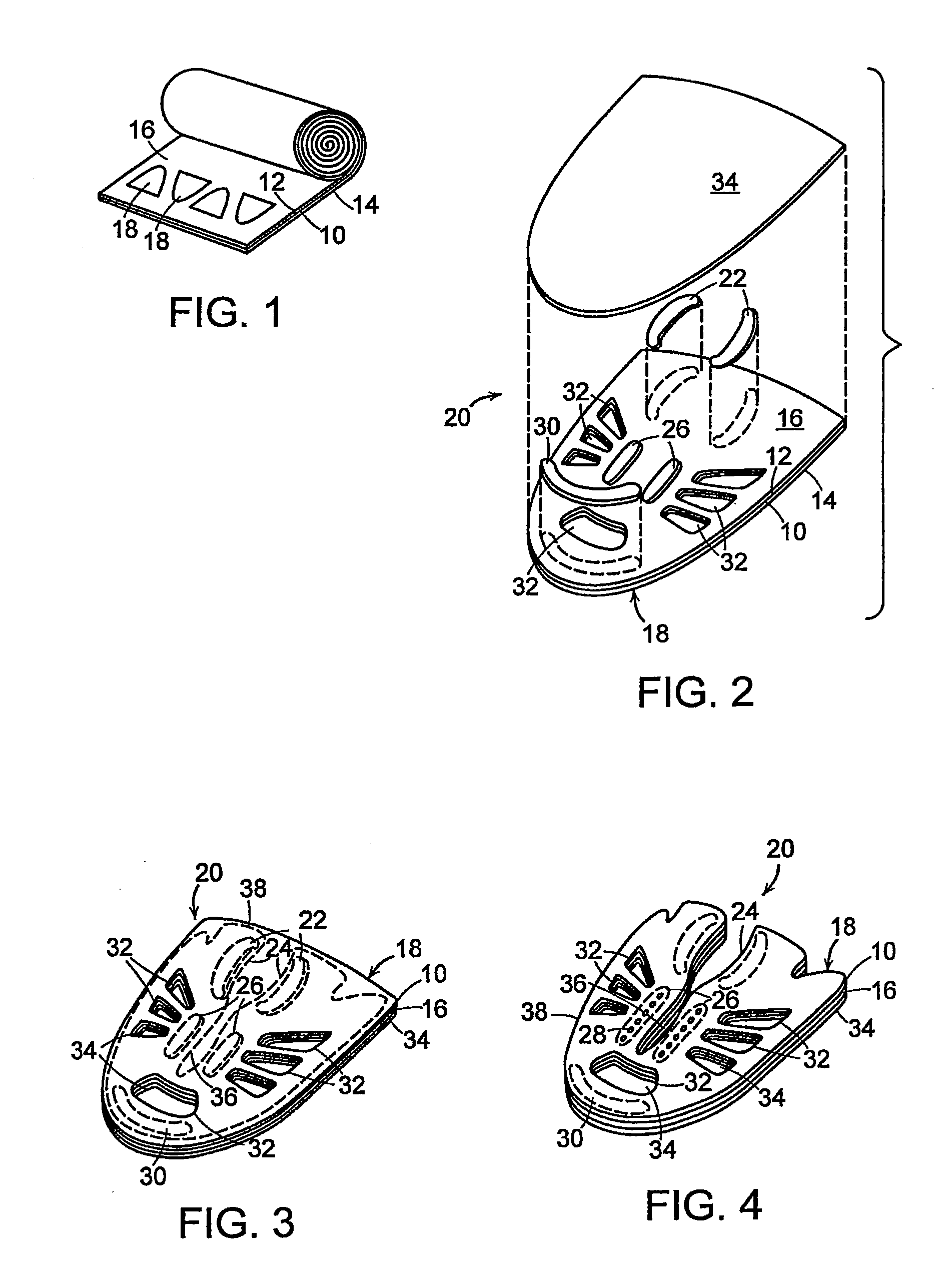

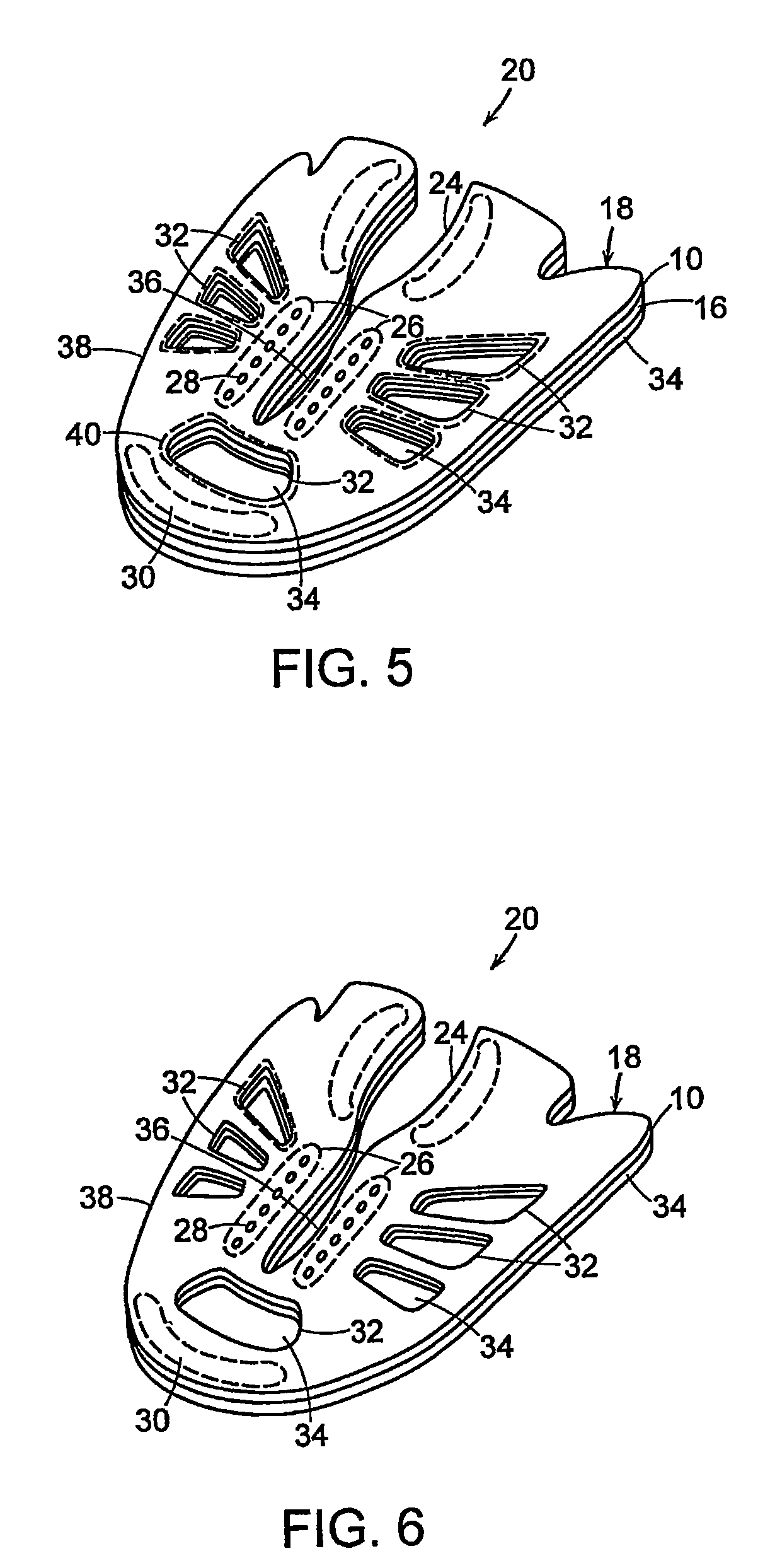

[0019] The present invention may be embodied in various forms. A preferred embodiment of a method of manufacturing an upper is illustrated in FIGS. 1-4. As can be seen in FIG. 1, a roll of material 10 has a first or interior surface 12 and a second or exterior surface 14. A layer of adhesive 16 is applied, by lamination or other suitable means, to interior surface 12. In a preferred embodiment, adhesive 16 is a hot-melt adhesive such as a thermoplastic polyurethane (TPU) based adhesive. A release liner (not shown) may be applied to the exposed surface of adhesive 16 in certain embodiments to prevent inadvertent adhesion of material 10 to other surfaces. In certain embodiments, adhesive layer 16 may be formed of a series of microdots rather than a contiguous layer of adhesive, which would provide additional breathability for a shoe upper 20 (seen in FIGS. 2-4).

[0020] An exterior layer 18 of shoe upper 20 is cut from material 10, with adhesive layer 16 forming the interior surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com