Variable displacement vane pump and method of controlling the same

a vane pump, variable-displacement technology, applied in the direction of machines/engines, positive-displacement liquid engines, liquid fuel engines, etc., can solve the problems and achieve the effect of increasing the size and weight of the solenoid valve and sufficient capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

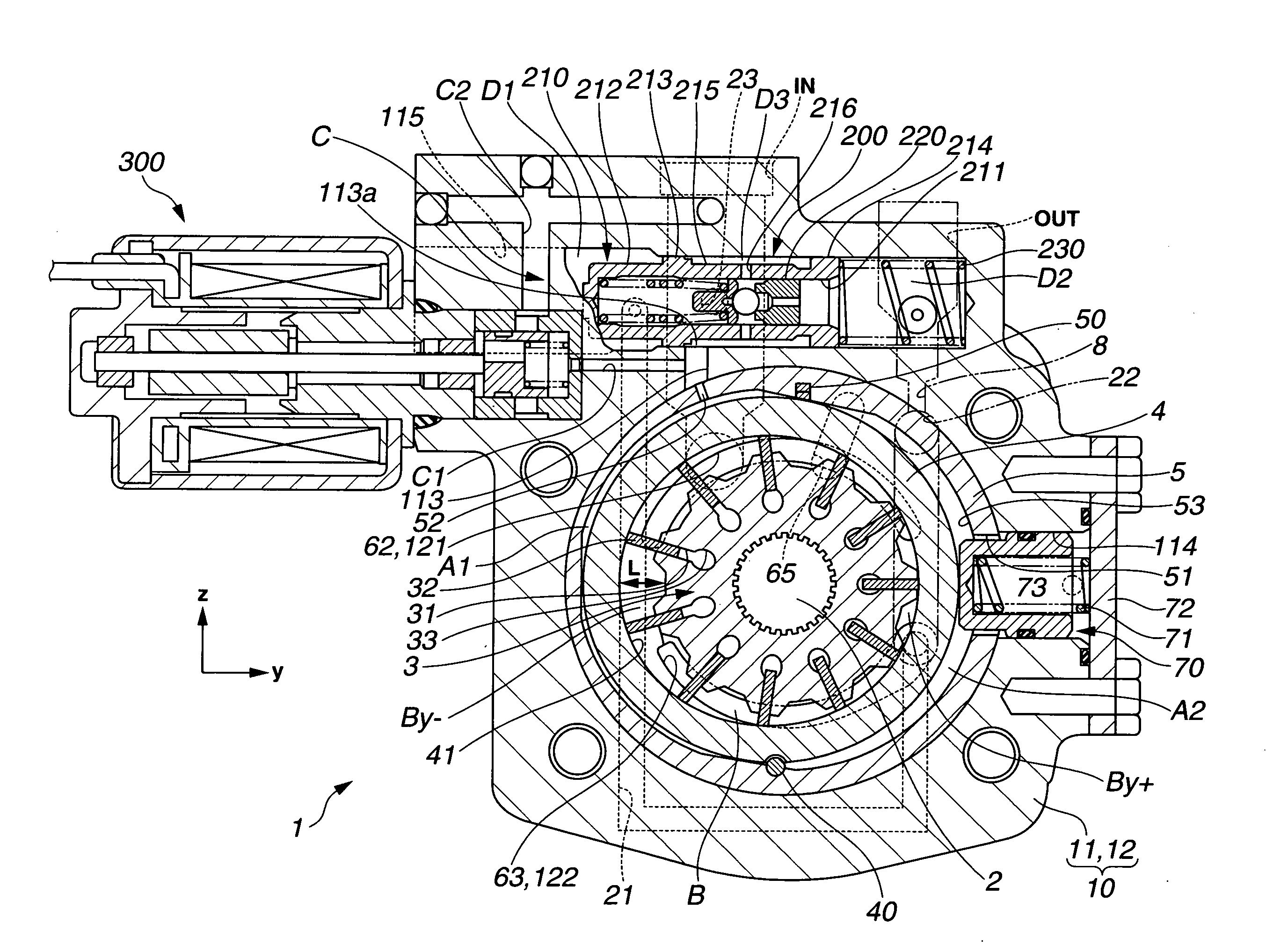

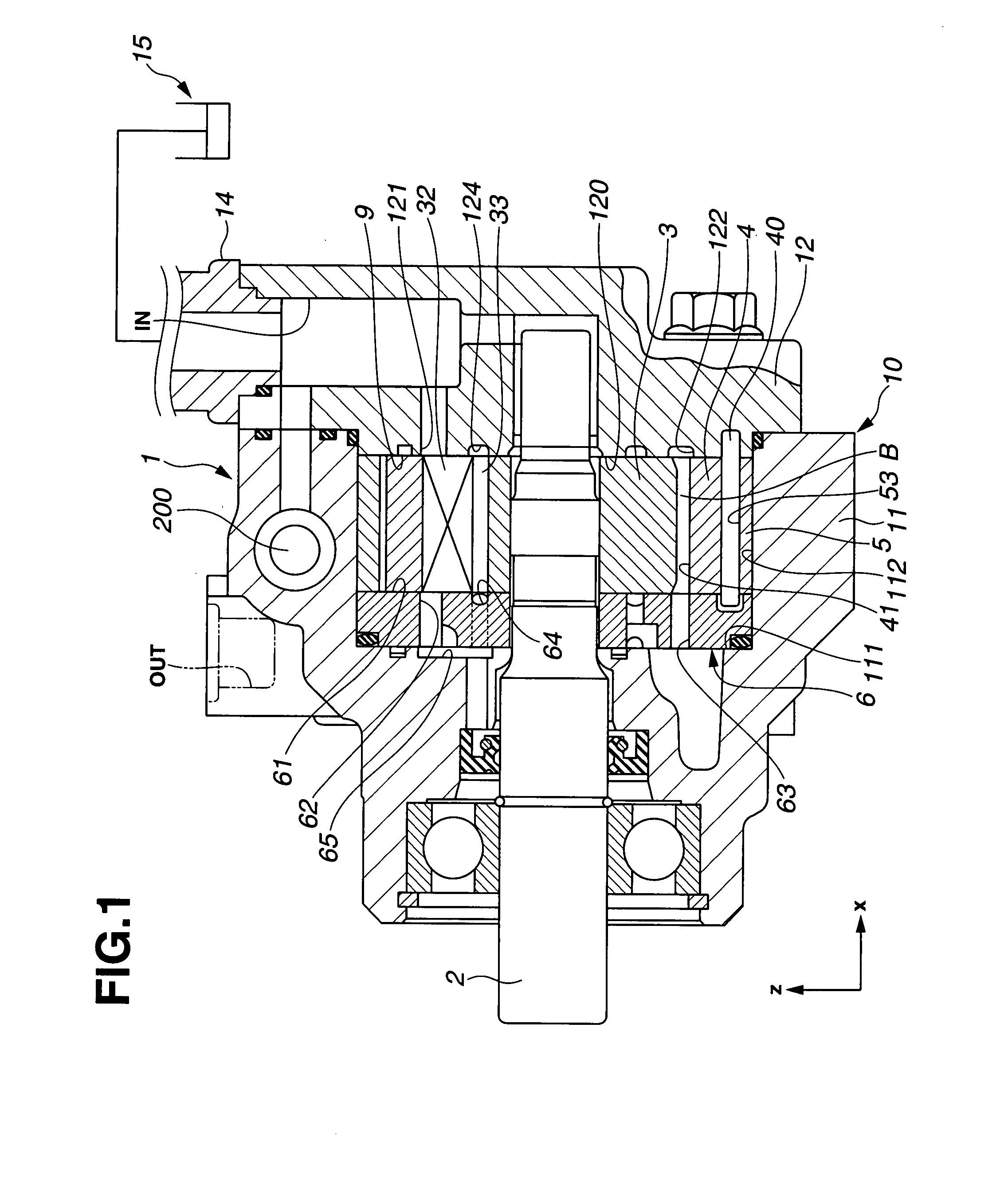

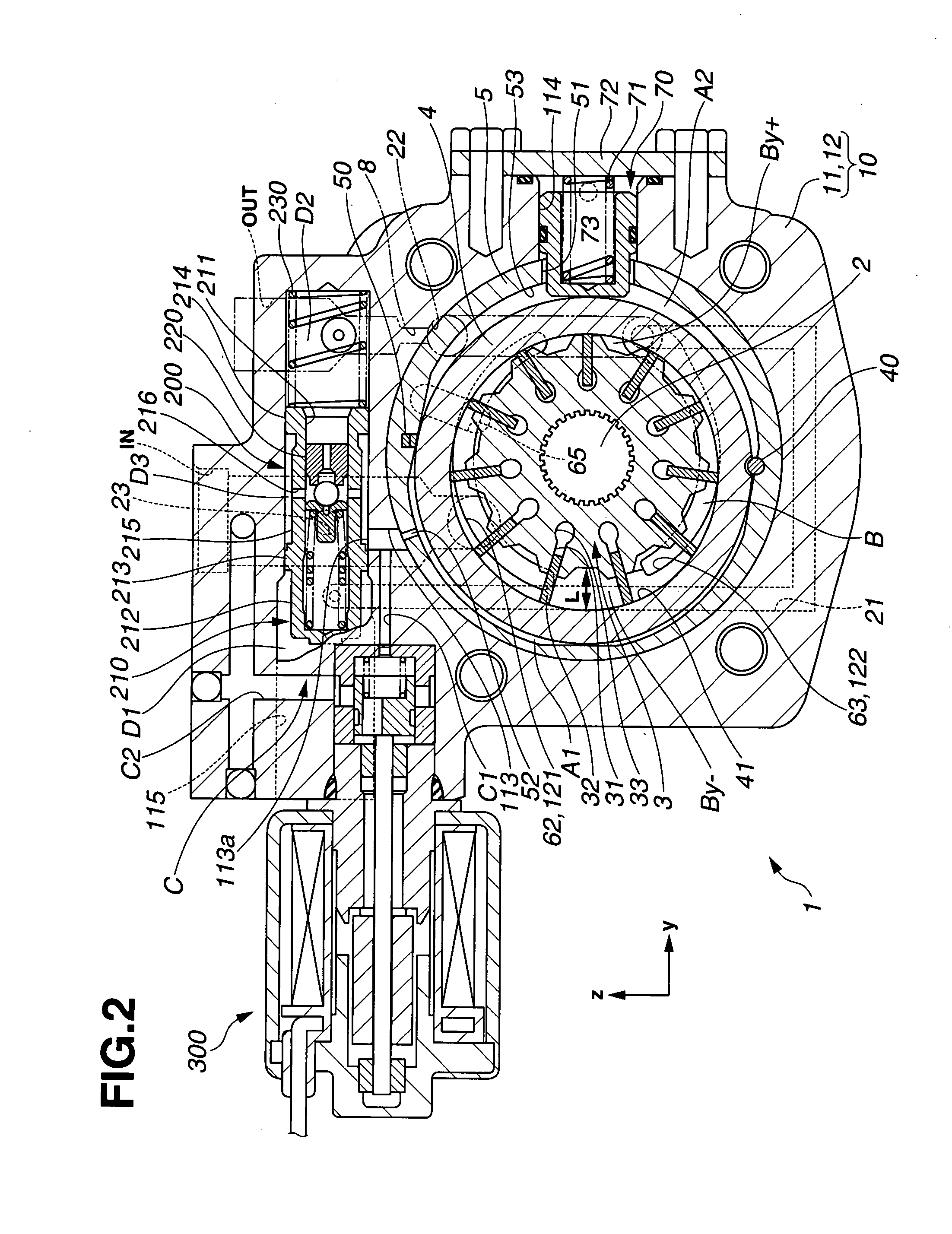

[0030]FIGS. 1, 2, 3 and 4 show a variable displacement vane pump in accordance with the present invention. A right-handed rectangular coordinate system (xyz) is provided in the drawings. In this variable displacement vane pump, a controlled fluid pressure is introduced into a first fluid pressure chamber, while a suction pressure is introduced into a second fluid pressure chamber, as described below in detail.

[0031]A variable displacement vane pump 1 generally includes a drive shaft 2, a rotor 3, a cam ring 4, an adapter ring 5, a pump body 10, a control valve 200, and an electromagnetic valve 300 in the form of a solenoid valve. Cam ring 4 is movably mounted within pump body 10, defining first and second fluid pressure chambers A1 and A2. Rotor 3 is mounted inside cam ring 4 at least for rotation about an axis in a direction, defining an annular chamber outside thereof. The axis of rotor 3 extends in the x-direction, while the direction of rotation of rotor 3 is counterclockwise as...

third embodiment

[0086]In the third embodiment, solenoid valve 300 is disposed on the positive y side and on the positive z side of adapter ring 5 in first housing 11 as shown in FIG. 9. Solenoid valve 300 is hydraulically connected to third fluid pressure chamber A3 through the fluid communication passage C3, and to suction passage IN through the fluid communication passage C4. Thus, third fluid pressure chamber A3 is connected to suction passage IN through the solenoid valve 300. Solenoid valve 300 selectively connects and disconnects the third fluid pressure chamber A3 to and from suction passage IN. While the internal pressure of third fluid pressure chamber A3 is equal to mixed pressure Pm (higher than suction pressure Pin), the opening operation of solenoid valve 300 allows the working fluid within third fluid pressure chamber A3 to flow out to suction passage IN, reducing the internal pressure of third fluid pressure chamber A3, P3.

[0087]FIG. 10 shows a variable displacement vane pump in acco...

fourth embodiment

[0090]FIG. 12 shows a variable displacement vane pump in accordance with a modification of the In this modification, solenoid valve 300 is hydraulically connected to discharge passage OUT through a fluid communication passage C4a. Solenoid valve 300 selectively connects and disconnects the third fluid pressure chamber A3 to and from discharge passage OUT. Control valve 200 constantly introduces the downstream discharge pressure Pfb into third fluid pressure chamber A3. While solenoid valve 300 is in an open state, the internal pressure of third fluid pressure chamber A3 is increased because downstream discharge pressure Pfb is lower than discharge pressure Pout.

[0091]FIGS. 13, 14 and 15 show a variable displacement vane pump in accordance with a fifth embodiment of the present invention. The fifth embodiment differs from the first embodiment in that the solenoid valve 300 is disposed close to suction passage IN, and solenoid valve 300 is hydraulically connected to first fluid press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com