Continuous real time heating value (BTU)/Coal flow balancing meter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

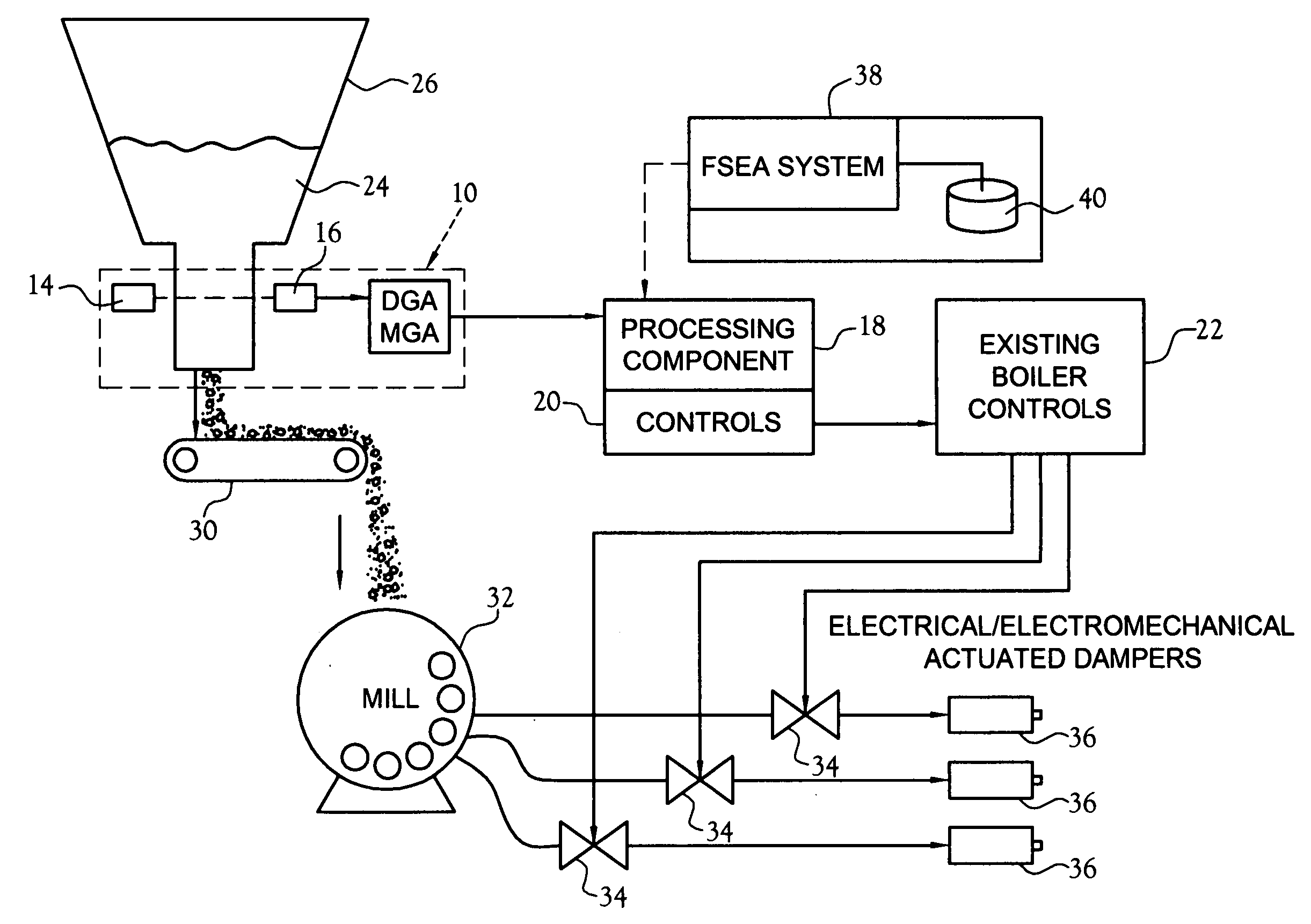

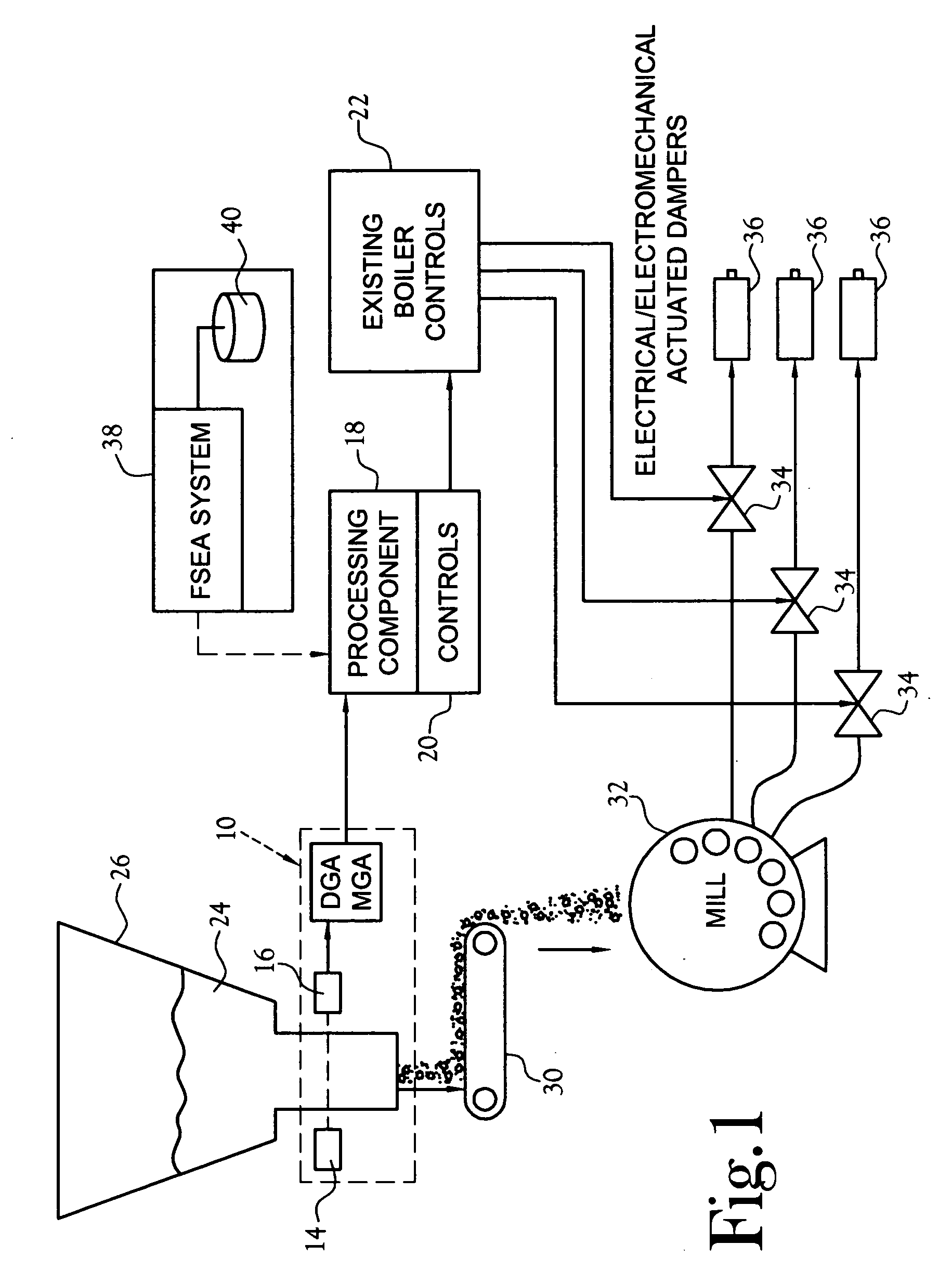

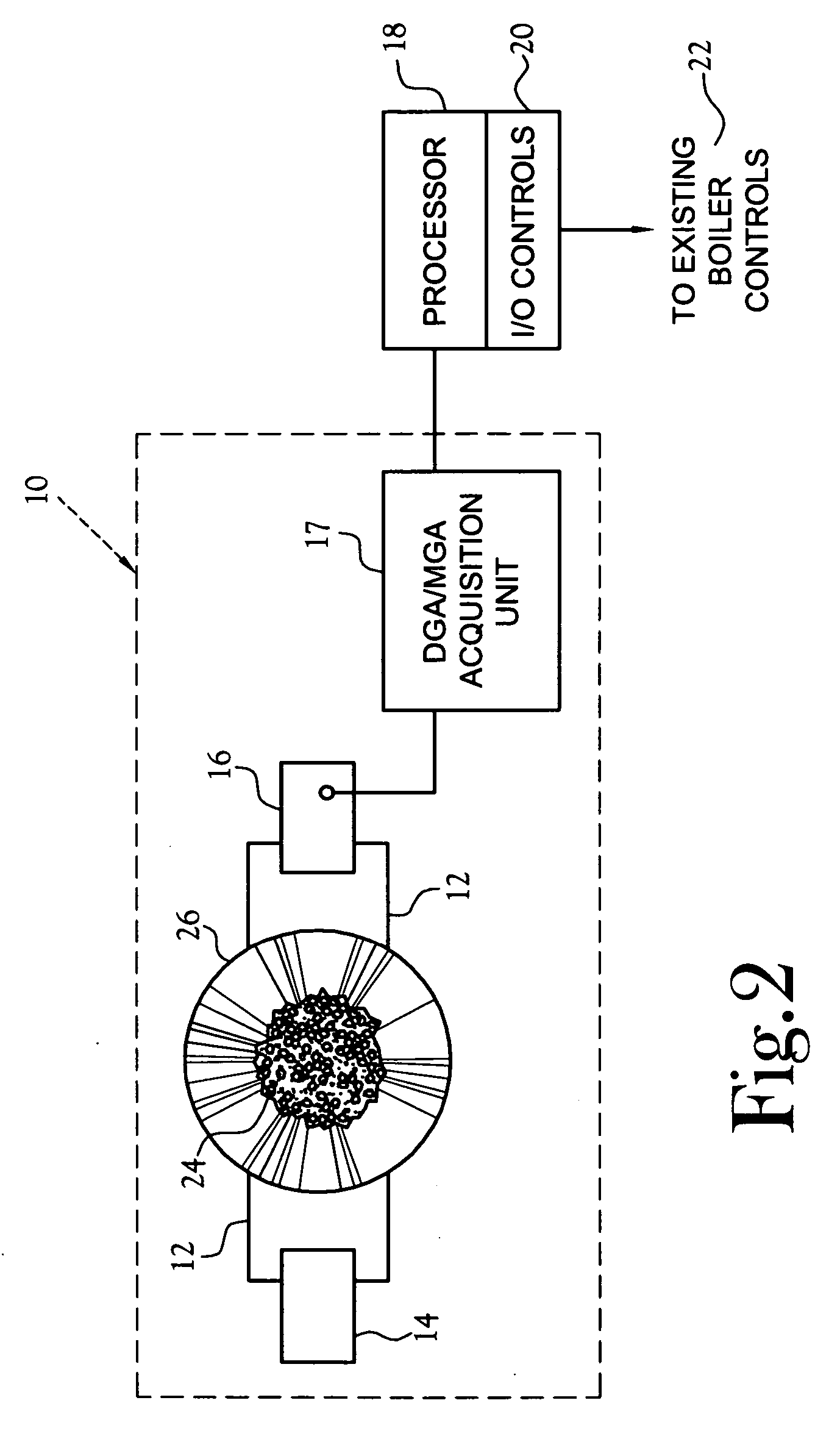

[0021] The present invention provides a method and an apparatus for continuous real time heating value / coal flow balancing of coal from a coal feeder to a burner. The apparatus includes a dual-energy Gamma Attenuation (DGA) / multi-energy Gamma Attenuation (MGA) device for measuring coal quality at a specific location in a coal fired plant in order to control the parameters of the plant according to the measured coal quality. By strategically placing the DGA / MGA device, continuous accurate real-time coal quality information is accomplished for making individual adjustments in order to improve stoichiometry to optimize performance of the system.

[0022] The DGA / MGA device of the present invention is illustrated generally at 10 in the figures. As described below, the DGA / MGA device 10 is mounted relative to a coal silo feeder tube 28 to determine the quality of the material flowing to the coal feeder 30. This coal quality information is fed to a processing component 18 where control logi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com