Tandem continuous-flow microbial fuel cell system and preparation method thereof, and application of tandem continuous-flow microbial fuel cell system in degradation of nitrobenzene wastewater

A fuel cell system, nitrobenzene wastewater technology, applied in biochemical fuel cells, biological water/sewage treatment, battery electrodes, etc., can solve the problems of difficult solvent regeneration, long treatment period, difficult biochemical degradation, etc., to promote electron transfer. rate, optimize system performance, and improve the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

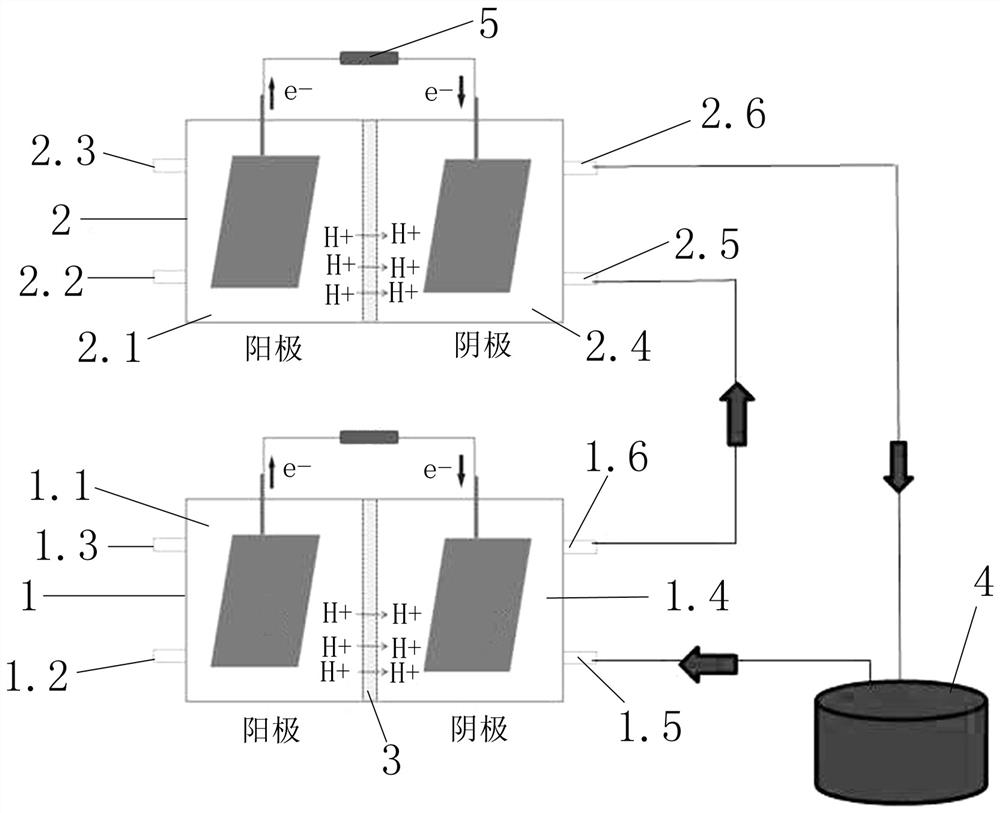

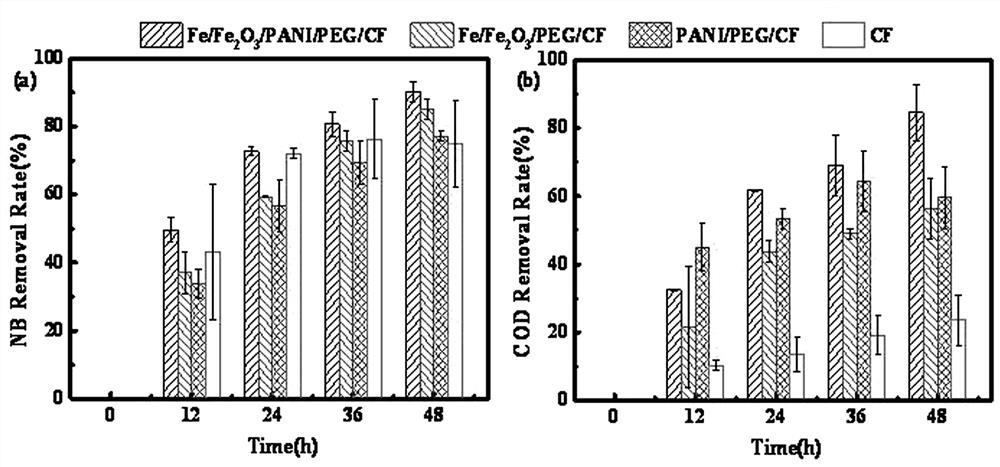

[0033] Embodiment 1: a kind of serial continuous flow microbial fuel cell system, is made up of two double-chamber microbial fuel cells MFC11, MFC2 2, the anode of MFC1 1 and MFC2 2 is left standstill respectively, and negative electrode is connected in series; The anode chamber of MFC1 and MFC2 is connected with The cathode chamber is separated by ion exchange membrane 3, and the electrodes in the anode chamber and cathode chamber of MFC1 and MFC2 are Fe@Fe 2 o 3 / PANI / PEG modified carbon felt; a saturated calomel electrode is set in the cathode chamber as a reference electrode; the anode and cathode are connected to a 1000Ω external resistor 5 through a copper wire to form a complete circuit loop, and a voltage collector is connected in parallel to the external resistor.

[0034] The two double-chamber microbial fuel cells MFC1 and MFC2 have the same structure. The anodes of the two MFCs are guaranteed to stand still, and the cathodes are connected in series. Each MFC is com...

Embodiment 2

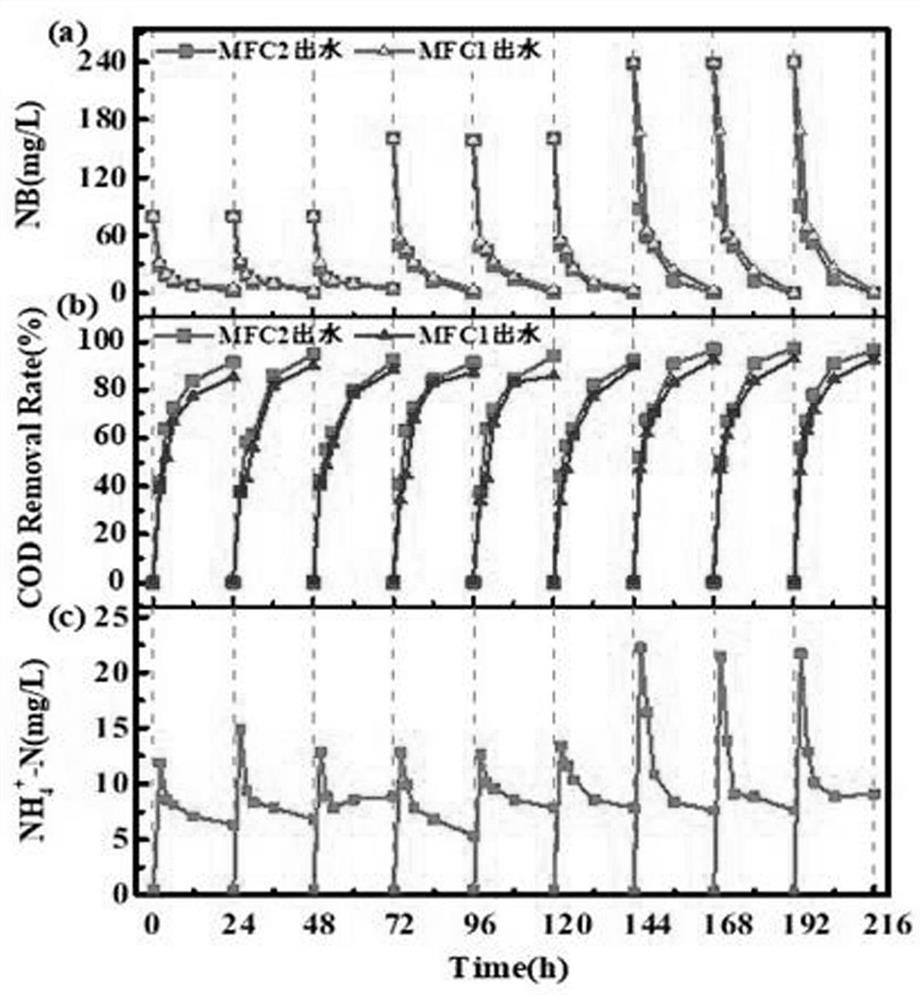

[0046] Embodiment 2: Utilize the series continuous flow microbial fuel cell system prepared in Example 1 to degrade nitrobenzene wastewater, the specific method is as follows: after the series continuous flow microbial fuel cell system is pretreated, film-hanged, and started, the nitrobenzene wastewater Entering the system: Nitrobenzene wastewater enters from the cathode water inlet I of MFC1, the upper cathode water of MFC1 is used as the lower cathode water of MFC2, and the water is discharged from the upper cathode of MFC2, and flows into the water inlet pool, and the cycle treatment is 24 hours according to this operation. After 24 hours of circulation treatment, a new batch of negative and positive medium was replaced. The water inlet and outlet of the anode are sealed and left standing, and the sampling can be opened when sampling is required.

[0047] Among them, the pretreatment is to sterilize and disinfect the reactors, instruments and other equipment; the film coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com