Structural reinforcement member and method of utilizing the same to reinforce a longitudinal section of an antenna support tower

a technology of structural reinforcement and longitudinal section, applied in the direction of towers, buildings, constructions, etc., can solve the problems of increasing the risk of fire, reducing the opportunity for damage due to heating, and reducing the risk of spacer locations along the pole, so as to reduce the risk of fire. , the effect of reducing the danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is directed to an assembly for reinforcing a longitudinal section of a pole segment, for non-limiting example, such as those found in communication poles, antenna or cellular towers.

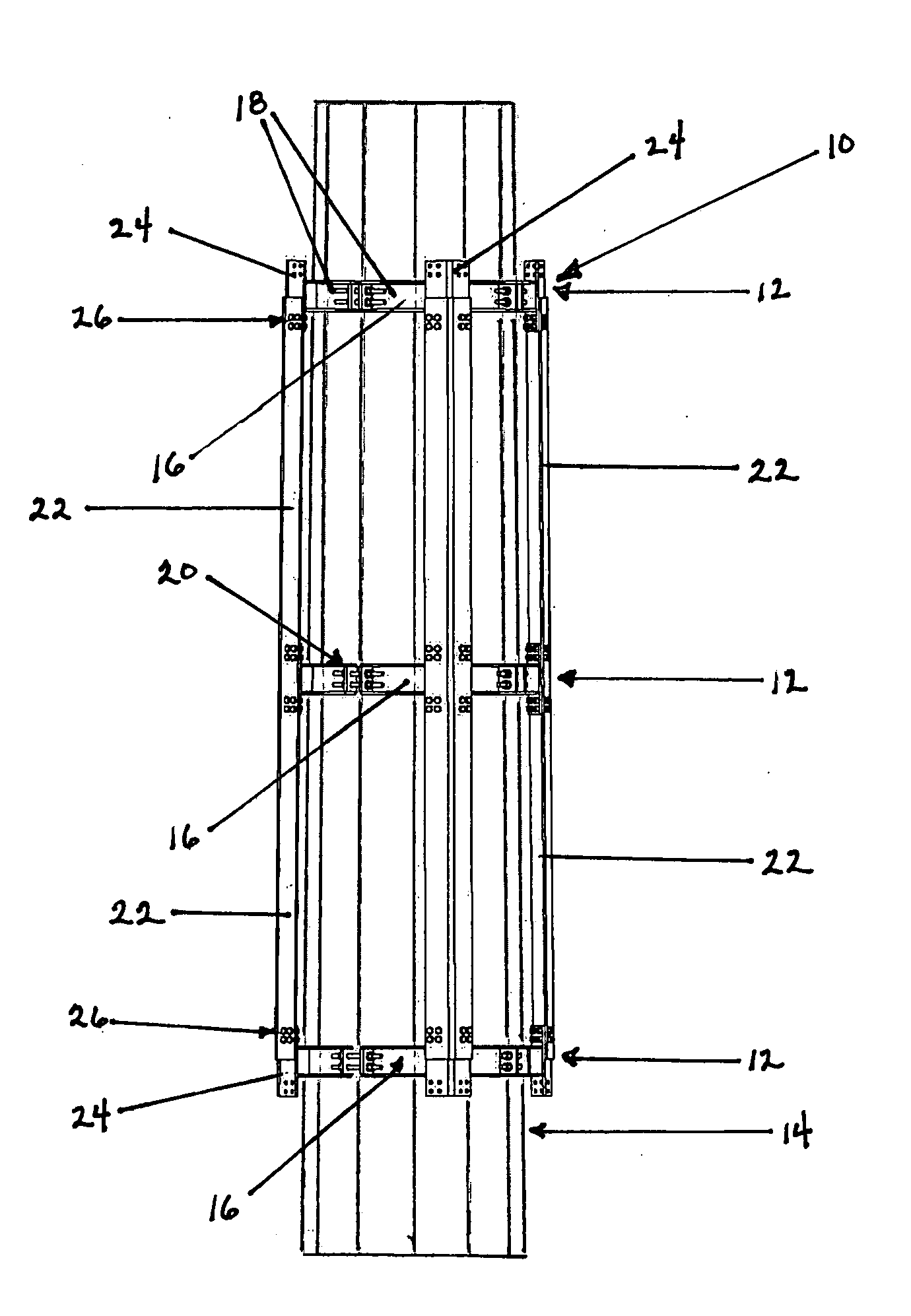

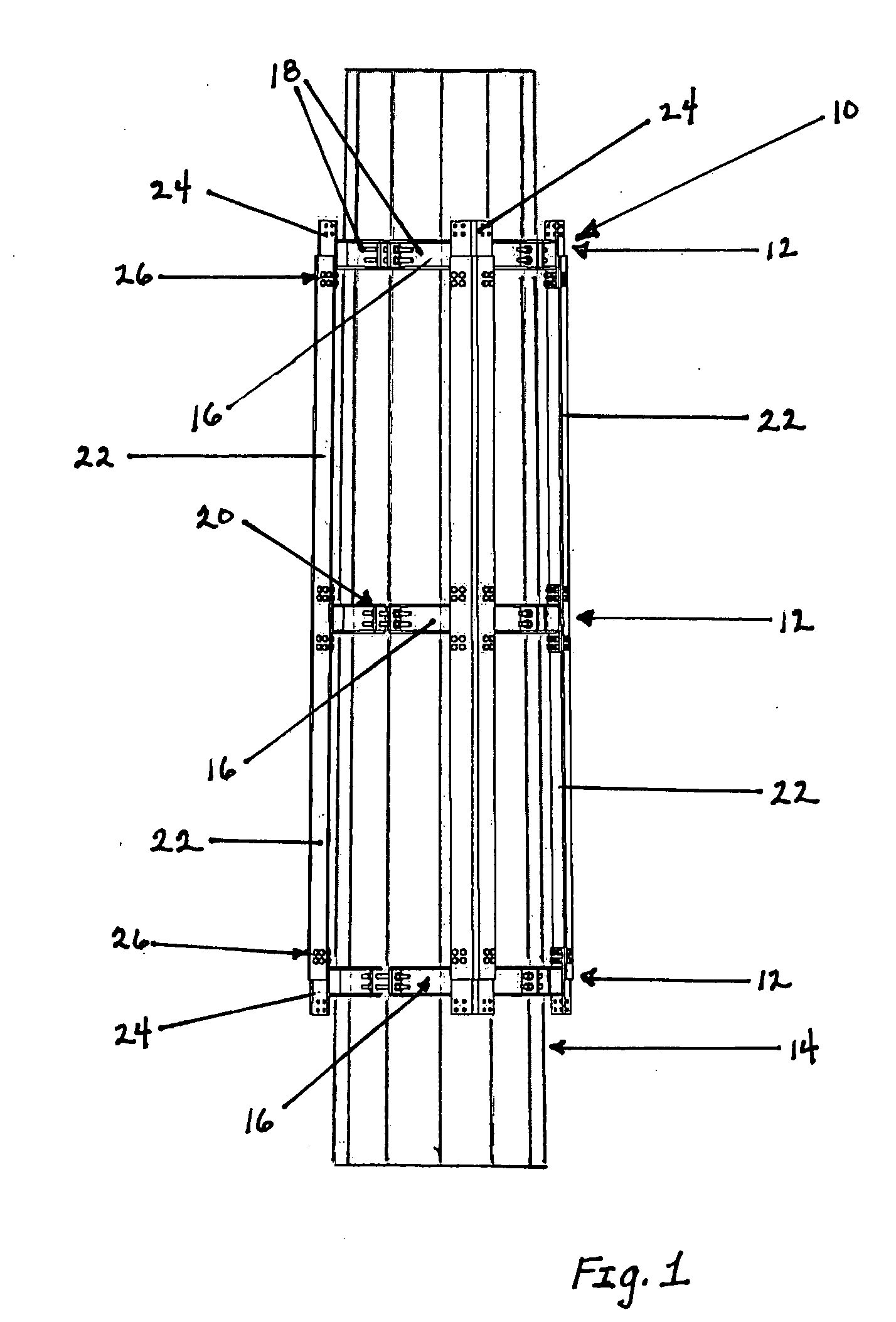

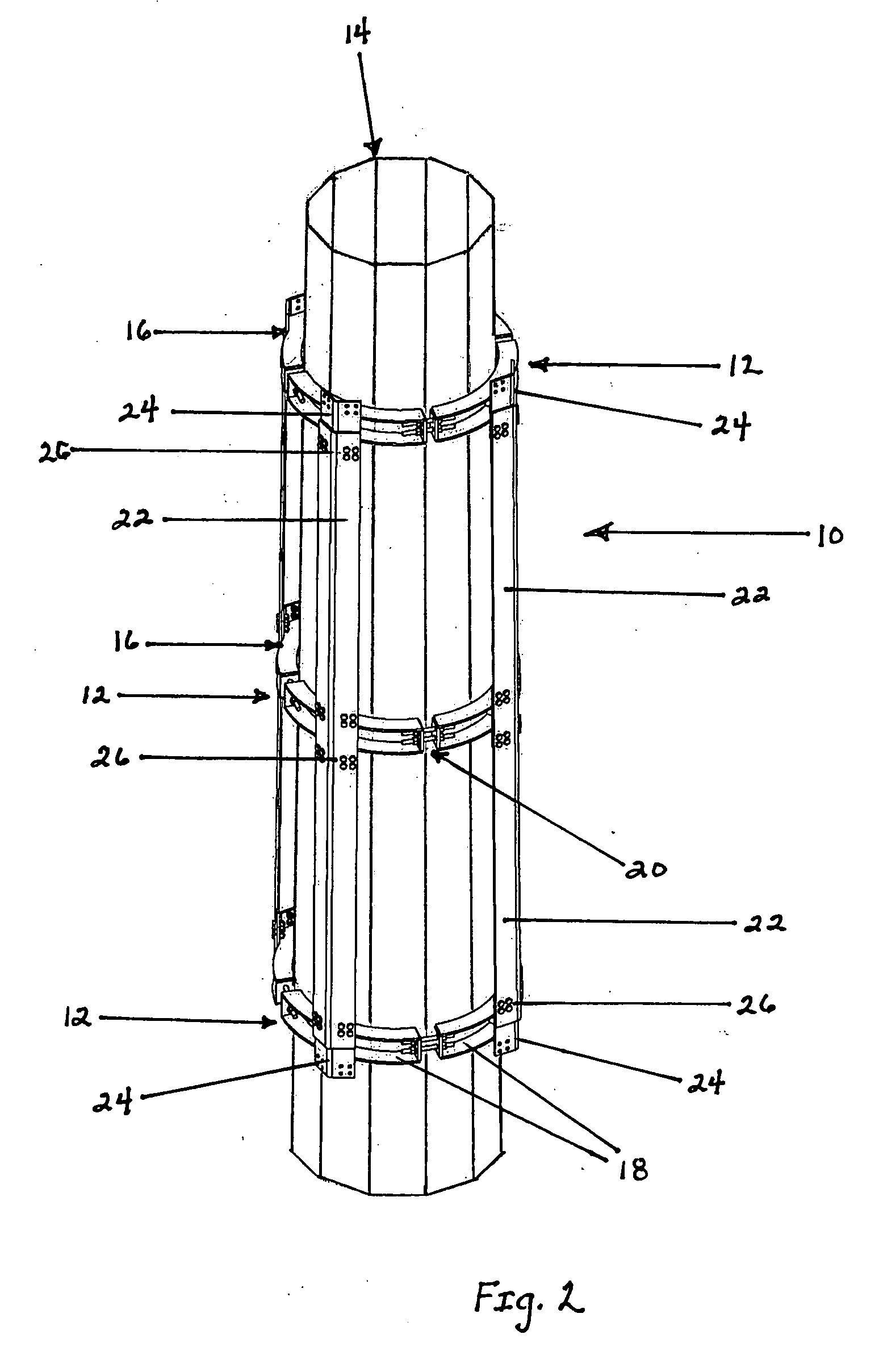

[0021] It is preferred that the reinforcing assembly 10 include a plurality of annular, load transfer rings 12 mounted along the longitudinal length of the pole 14 that is to be strengthened, as illustrated in FIGS. 1 and 2 of the accompanying drawings. These load transfer rings are placed along the longitudinal length of the communication pole in a spaced apart relationship. For ease in installing the rings onto the pole, it is preferred that the rings be formed from a plurality of individual, standardized sleeve segments 16 having radically opposed mating ends 18 best seen in FIG. 3. Once the segments 16 are joined at ends 18, they form the load transfer ring 12 and are adapted to fit onto the outer surface of the pole 14 so as to circumferentially encompass the pole as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com