Method of opening for bags of supple polymeric material subject to interlayer cling

a polymeric material and interlayer technology, applied in the field of plastic bags, can solve the problems of difficult opening of bags made of supple polymeric materials, little that can be done to formulations, and difficult bags, etc., and achieve the effect of easy handling, easy opening, and intelligence in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

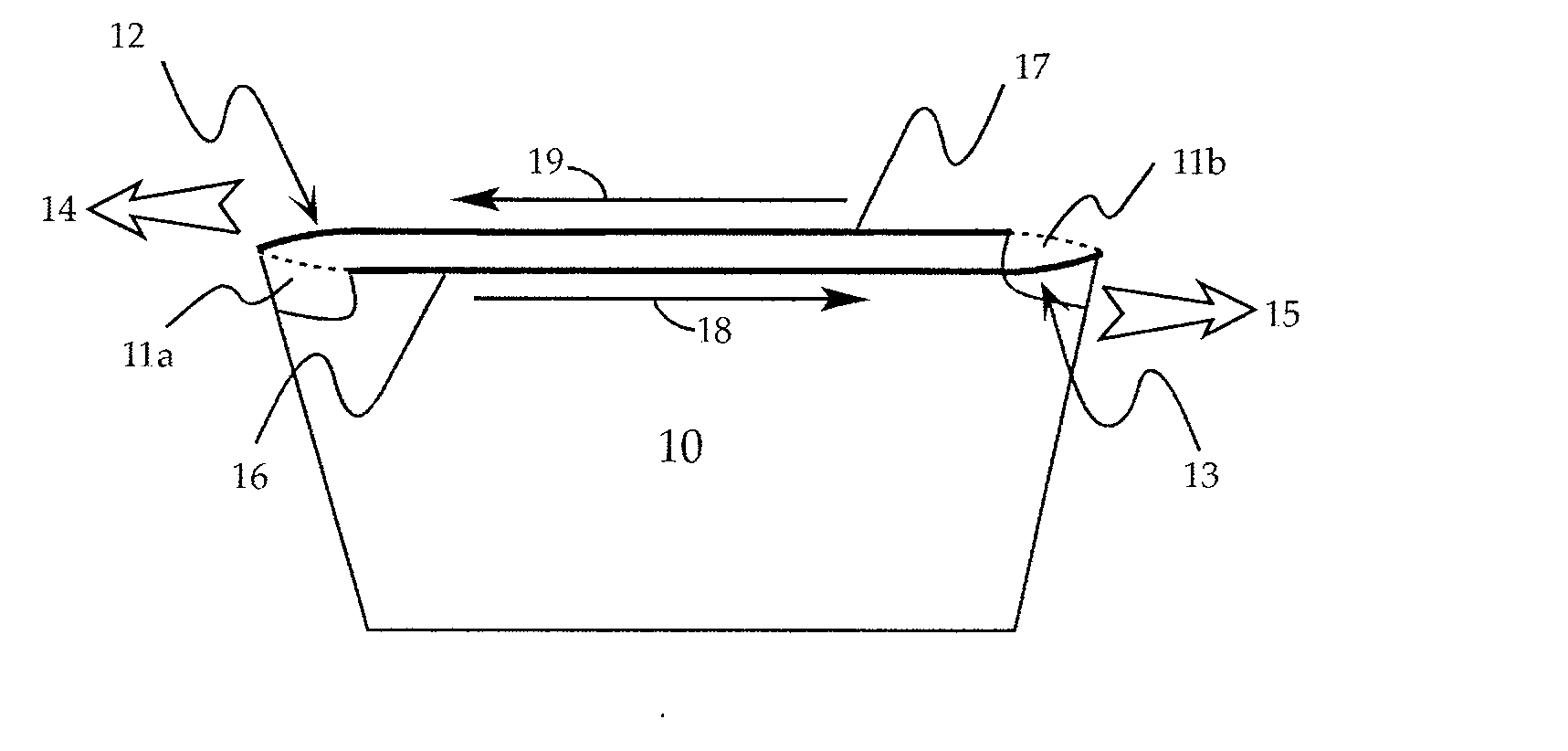

[0035] Illustrating the application of exposed graspable sidewall portions to a flat bag to be opened manually, FIG. 1 shows a bag 10 having flat first and second sidewalls 16 and 17 with graspable sidewall portions 12 and 13 exposed by voids or weakenings 11a and 11b in the opposing sidewalls, such that when the exposed graspable sidewall portions 12 and 13 are grasped and tensioned slightly in directions 14 and 15 respectively, a shearing of the first sidewall 16 occurs in direction 18 opposite to the direction 19 of motion of the second sidewall 17, thus disrupting the interlayer cling that otherwise could render the bag difficult to open.

[0036] The placement of the voids 11a and 11b near the edges allows a simple action to disrupt interlayer cling across virtually the entire bag width; placement at the extreme edges of the bag has the additional advantage in manufacturing: as bags are being produced in a side-by-side configuration as is common for side-welded bags, in that a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com