Spiral rope for liana raising, manufacturing method for the spiral rope and wall surface greening system

a manufacturing method and spiral rope technology, applied in the field of spiral rope for liana raising, can solve the problems of deterioration of appearance, difficulty in smoothly winding the liana around the rope, and possible separation from the rop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

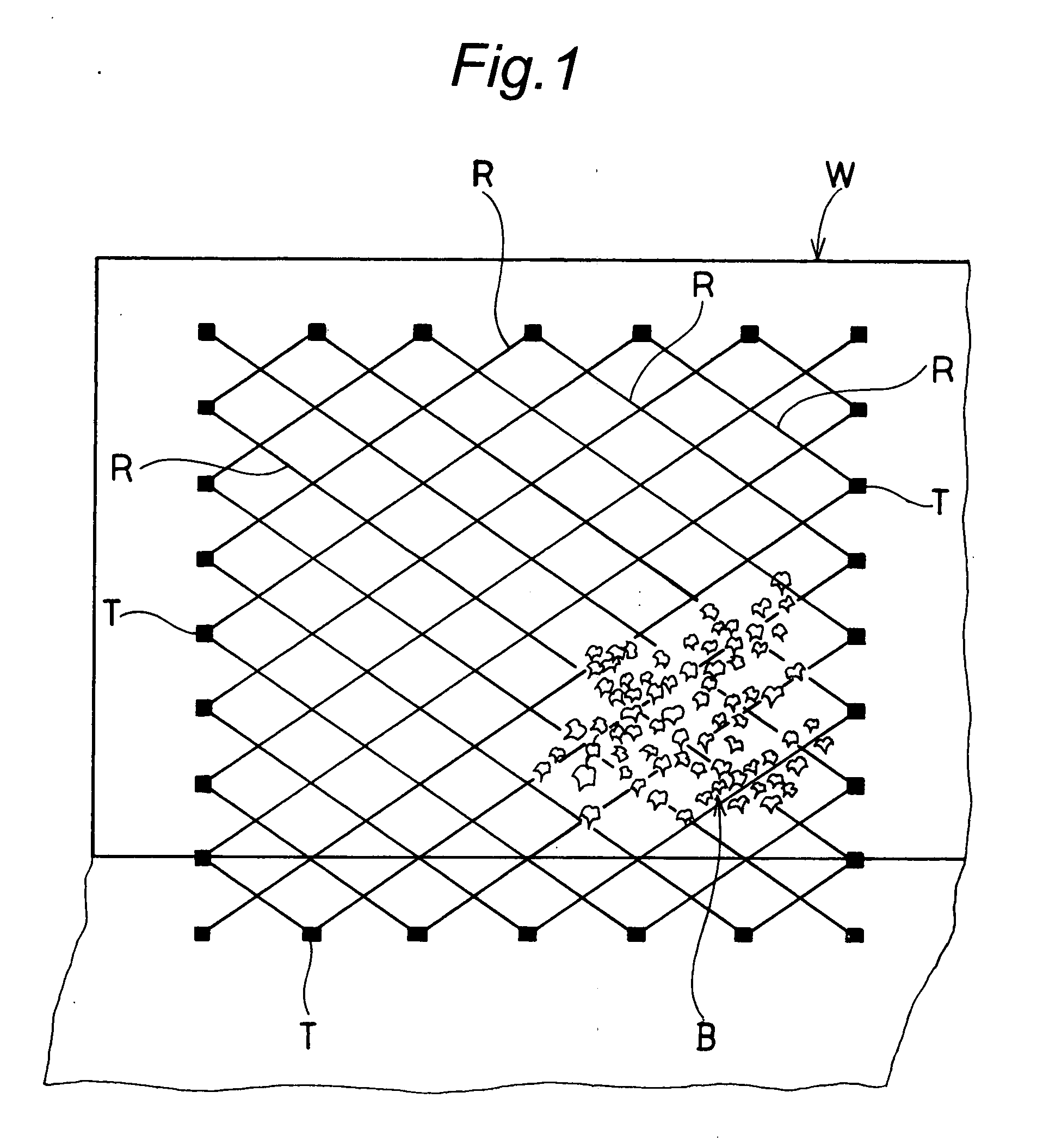

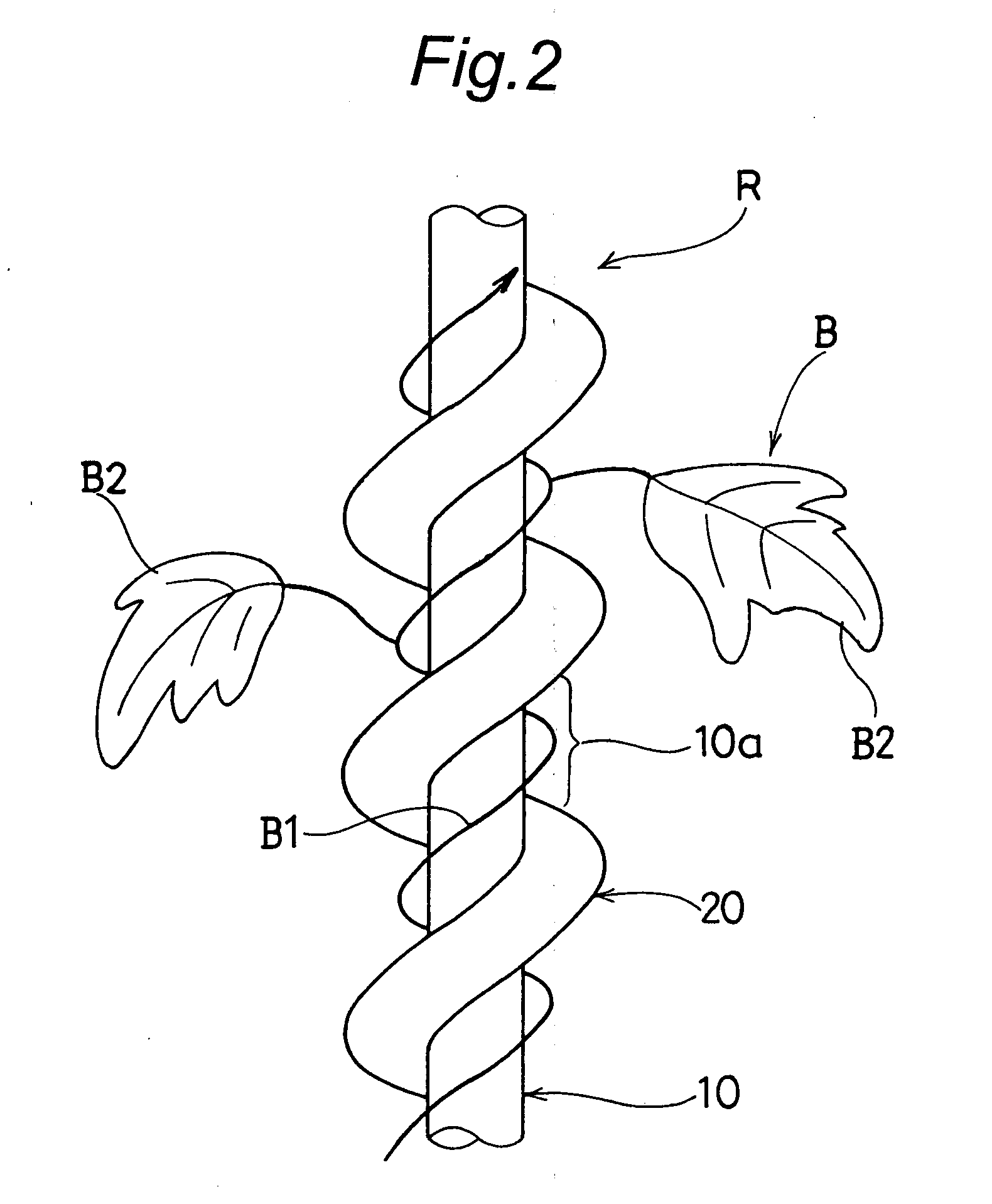

[0062]These spiral ropes Rare, as shown in FIG. 1, supported by a plurality of tightening metallic fittings T between an upper portion of a wall surface W and the ground in such a manner that they are opposed to the wall surface W in an inclined state against the wall surface W with a diamond cross pattern, which is one of predetermined stretching patterns. In the first embodiment, a liana B is, in FIGS. 1 and 2, shown as an example which grows along the wall surface greening system.

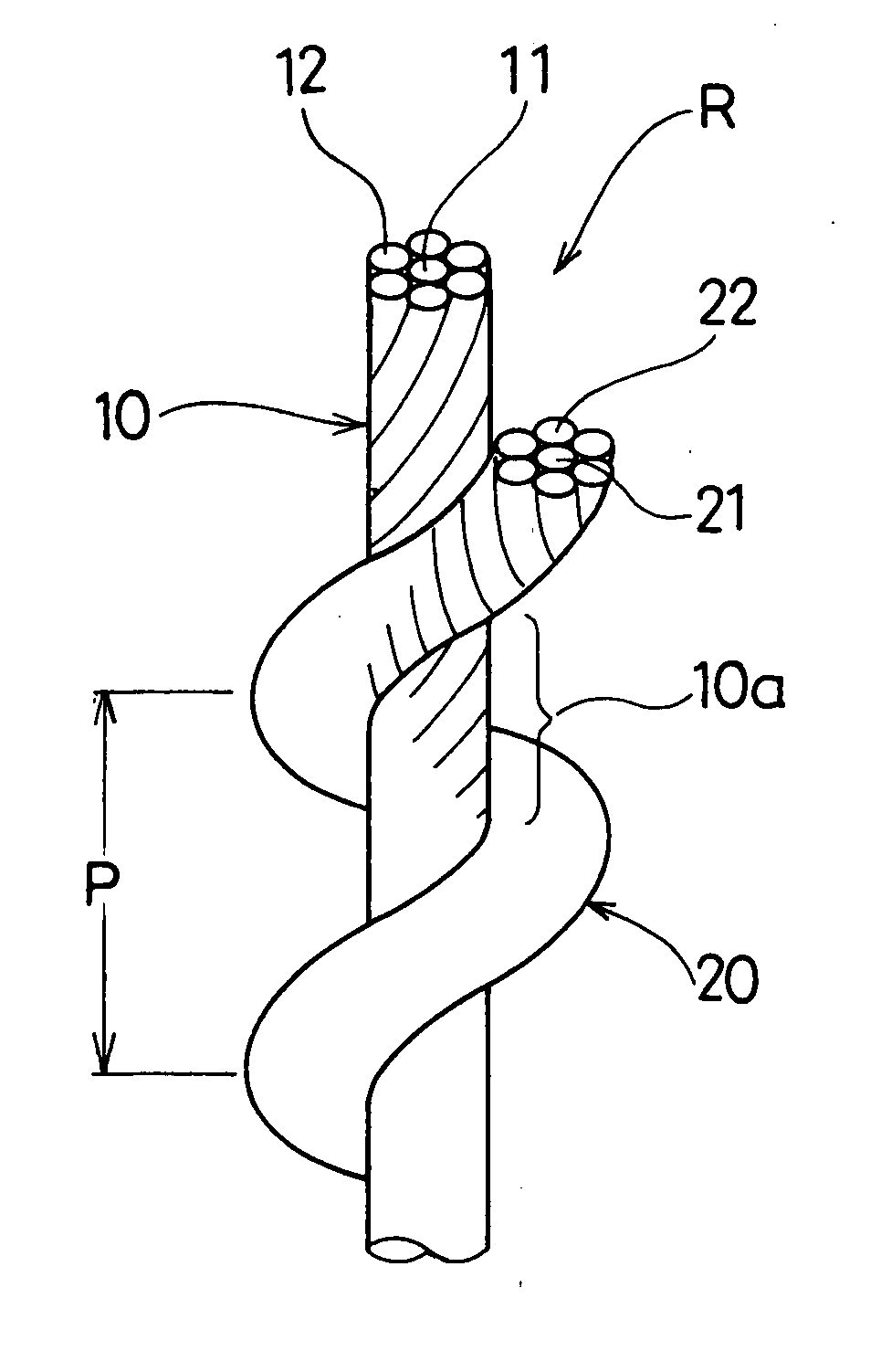

[0063]The spiral rope R has, as shown in FIGS. 2 and 3, a core member 10 and a side member 20. The core member 10 is formed as a twisted wire including one core element wire 11 around which 6 or six side element wires 12 are twisted in Z-like shape (see FIG. 3).

[0064]The side member 20 is formed as a twisted wire including one core element wire 21 around which 6 or six side element wires 22 are twisted into a S-like shape. The side member 20 is spirally wound around the core member 10 along the longitudi...

second embodiment

[0102]In the second embodiment, in the core rope member Ra, the outer diameter of the core strand is 0.77 mm, and the outer diameter of the element wire consisting of the core of the core strand 30 is 0.27 mm. The outer diameter of the element wire of the side strand consisting of the side portions of the core strand 30 is 0.25 mm, and the outer diameter of the side strand 40 is 0.66 mm. Further, the outer diameter of the element wire consisting of the core of the side strand 40 is 0.22 mm and the outer diameter of the element wire of the side strand consisting of the side portions of the side strand 40 is 0.22 mm.

[0103]As shown in FIG. 10, the side rope member Rb is constructed as a twisted wire in which six side element wires 52 are twisted around one core element wire 51 at a twisting pitch of 6.40 mm in the form of the Z-like shape. In this embodiment, the core element wire 51 and the respective side element wires 52 are made of the austenite-based stainless steel wires describe...

third embodiment

[0119]In the third embodiment as constructed above, in the spiral rope R2, four bundles of the side strands 20A are, as described above, wound around the core strand 10A in the counter-clockwise direction (in the twisting direction in the form of the Z-like shape) in such a manner that they extend along the winding direction (counter-clockwise direction) of the twiner B1 of the liana B which grows in the Northern Hemisphere of the earth. Furthermore, the spiral grooves 10c are formed around the outer periphery of the core strand 10A as described above (see FIG. 11).

[0120]Therefore, the liana B grows, as same as the first embodiment, in such a manner that the twiner B1 winds smoothly around the core strand 10A in the clockwise direction along the spiral grooves 10c. As a result, the same effects as those of the first embodiment can be also achieved in this third embodiment.

[0121]Further, as described above, the spiral rope R2 has the structure with two bundles of side strands lacked....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com