Porous Sound Absorbing Structure

a sound absorbing structure and porous technology, applied in the direction of walls, flooring, instruments, etc., can solve the problems of clogging through holes, affecting exerting the sound absorbing effect, so as to achieve sufficient sound absorbing performance and promote the conversion of air vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

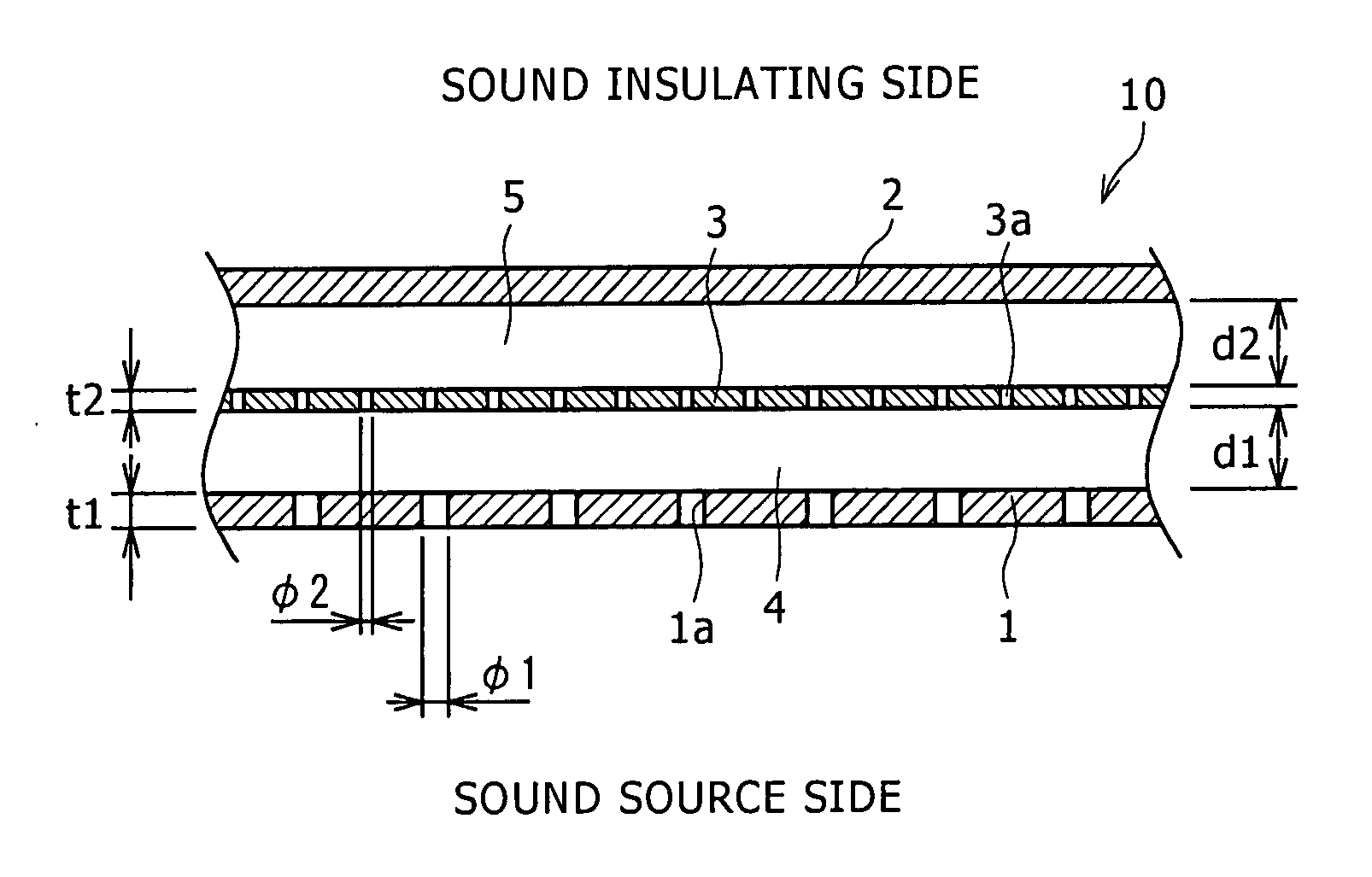

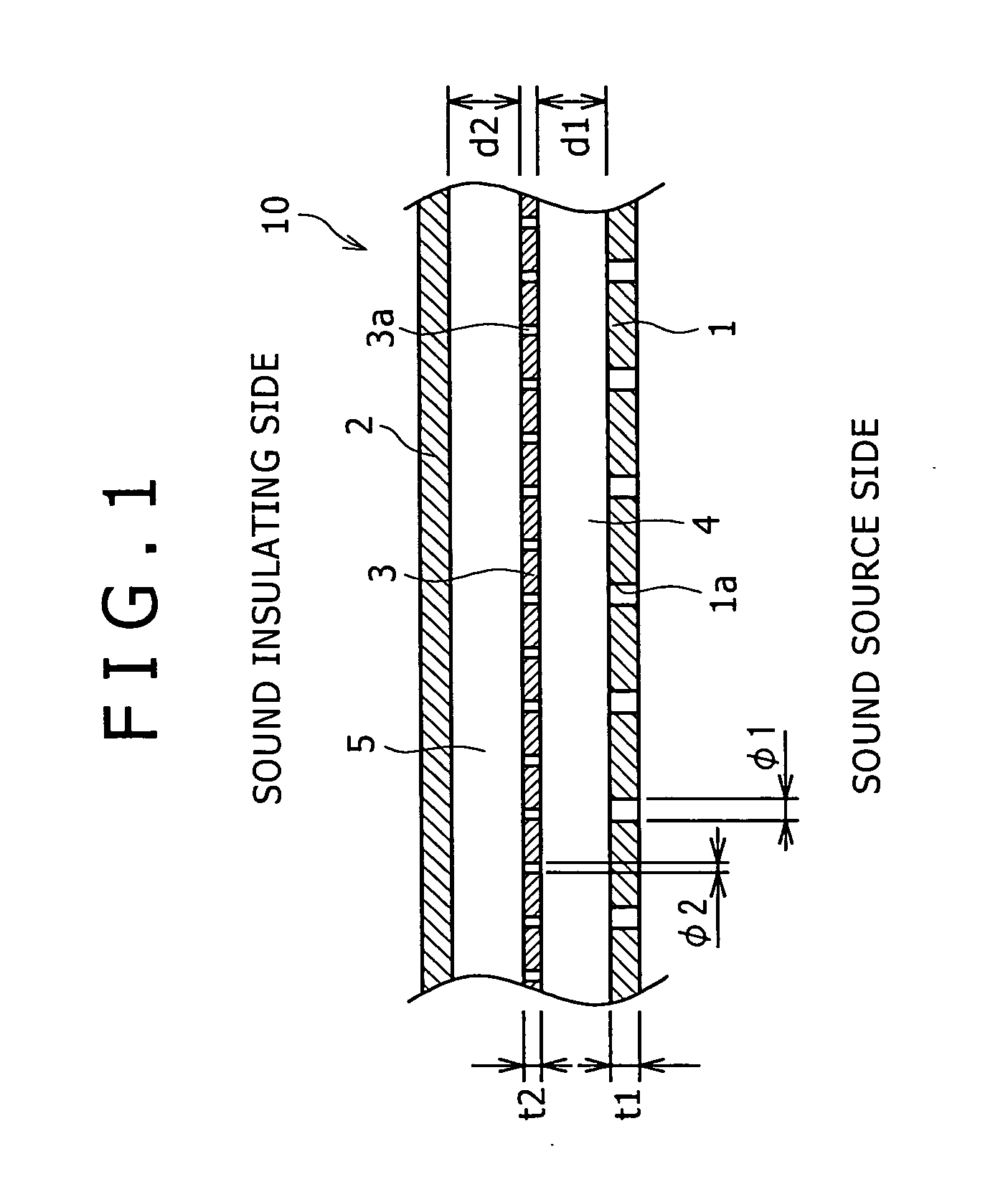

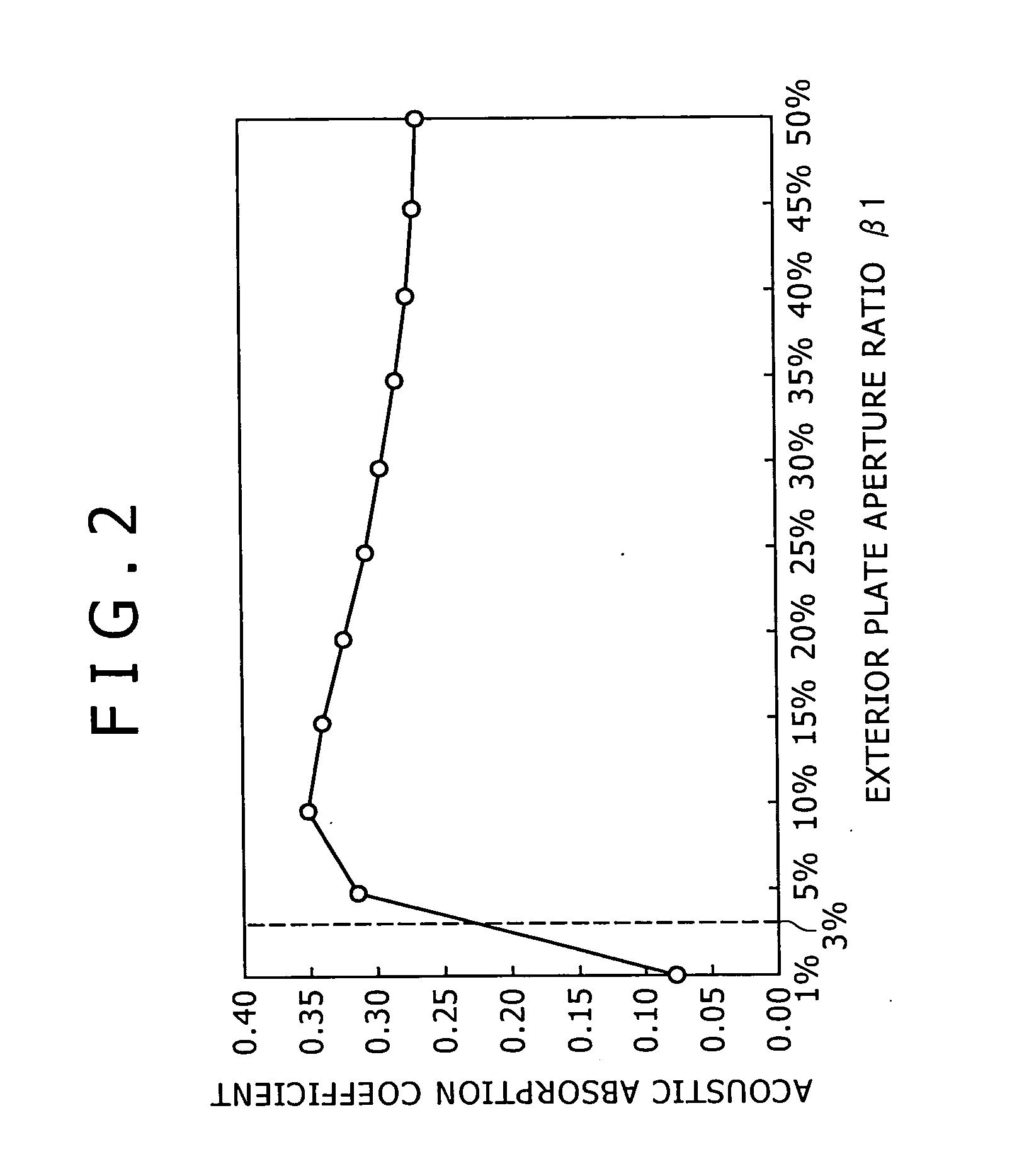

[0045]FIG. 1 is a transverse sectional view showing a porous sound absorbing structure according to a first embodiment of the present invention. As shown in FIG. 1, a porous sound absorbing structure 10 according to the first embodiment includes an exterior plate (second outside member) 1, a closing plate (first outside member) 2, and an interior plate (inside member) 3. The exterior plate 1 is arranged on the sound source side, the closing plate 2 is arranged on the sound insulating side, and the interior plate 3 is arranged between the exterior plate 1 and the closing plate 2. An air layer 4 is located between the interior plate 3 and the exterior plate 1, and an air layer 5 is located between the interior plate 3 and closing plate 2. The exterior plate 1, the closing plate 2, and the interior plate 3 are made of a metal such as iron and aluminum, a synthetic resin, a fiber reinforced material, and the like. Desirably the exterior plate 1, the closing plate 2, and the interior pla...

second embodiment

[0058]FIG. 7 is a transverse sectional view showing a porous sound absorbing structure according to a second embodiment of the present invention. As shown in FIG. 7, a porous sound absorbing structure 20 of the second embodiment has the substantially same configuration as the porous sound absorbing structure 10 of the first embodiment except that a glass wool (sound absorbing material) 21 is arranged in the air layer 5 of the porous sound absorbing structure 10 of the first embodiment. In FIG. 7, the same component as the first embodiment is designated by the same numeral, and the description will be omitted.

[0059] In the second embodiment, although the glass wool 21 is provided in the air layer 5, for example, the sound absorbing material made of the metal fiber, the foam metal and resin metal thin film or the metal thin film, or the non-oven cloth may be provided in the air layer 5. The glass wool 21 may be provided not only in the air layer 5 but in the air layer 4, or the glass...

third embodiment

[0061]FIG. 8 is a transverse sectional view showing a porous sound absorbing structure according to a third embodiment of the present invention. As shown in FIG. 8, a porous sound absorbing structure 30 of the third embodiment has the substantially same configuration as the porous sound absorbing structure 10 of the first embodiment except that multiple thin films 31 are arranged so as to vertically partition the air layer 5 of the porous sound absorbing structure 10 of the first embodiment. In FIG. 8, the same component as the above-described embodiments is designated by the same numeral, and the description will be omitted.

[0062] In the multiple thin films 31, two thin films 32 and 33 are laminated while being adjacent to each other. Many through holes 32a and 33a are made in the thin films 32 and 33 respectively, and the through holes 32a and 33a have the same aperture ratios and diameters as the interior plate 3. As shown in FIG. 8, the through holes 32a and 33a in the two thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com