Cleaning method and cleaning apparatus

a cleaning method and cleaning technology, applied in the direction of photomechanical equipment, instruments, originals for photomechanical treatment, etc., can solve the problems of difficult purging of remaining additives from the end pipe in the rinsing process, damage to the fine structure, etc., to prevent the flow of liquidized additives and reduce the pressure in the substrate cleaning bath

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

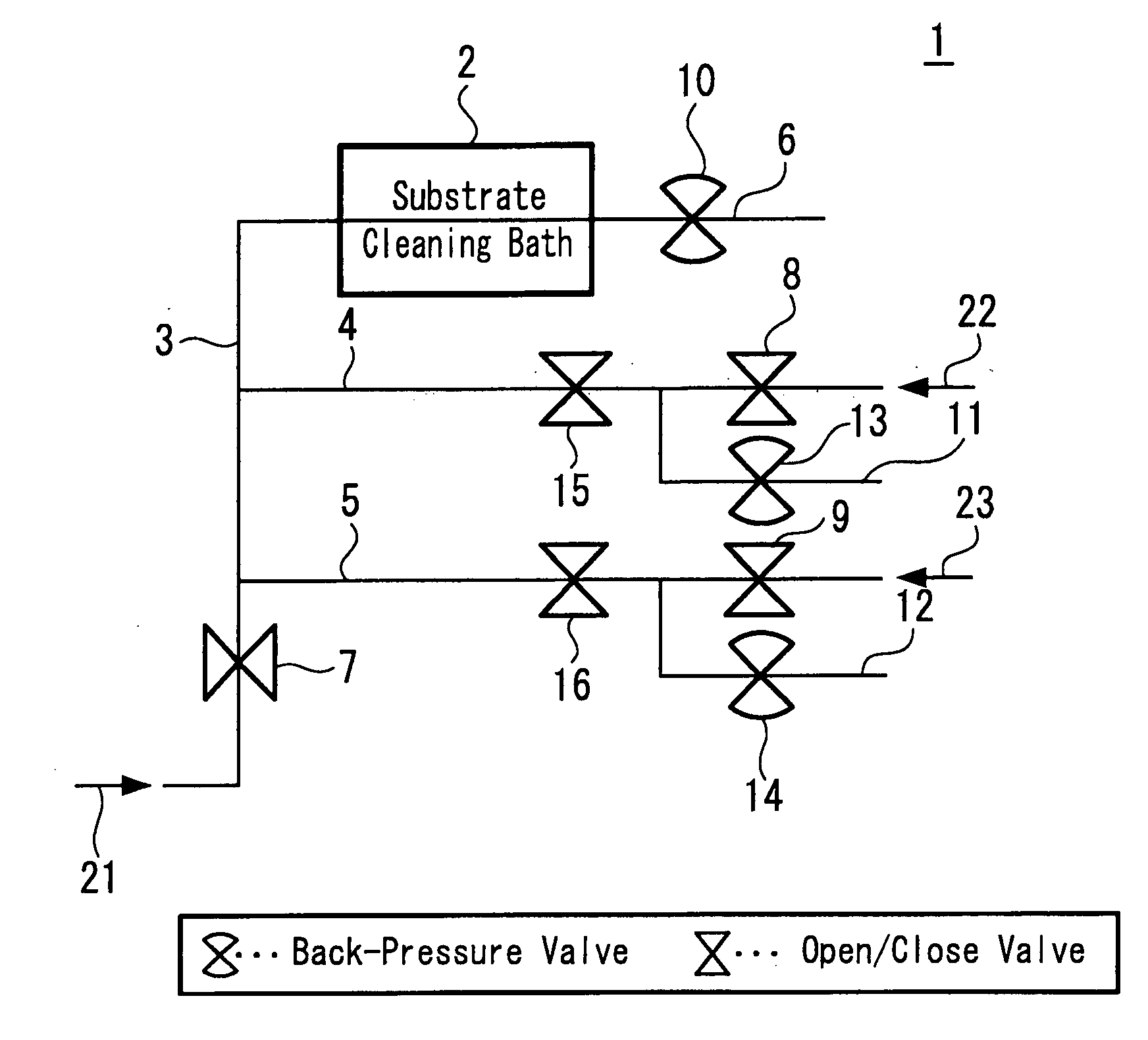

first embodiment

[0056]Next, a cleaning method for cleaning an object, for example, a semiconductor wafer (hereinafter referred to as a “wafer”) using the supercritical cleaning apparatus 1 according to the embodiment will be described with operation processes.

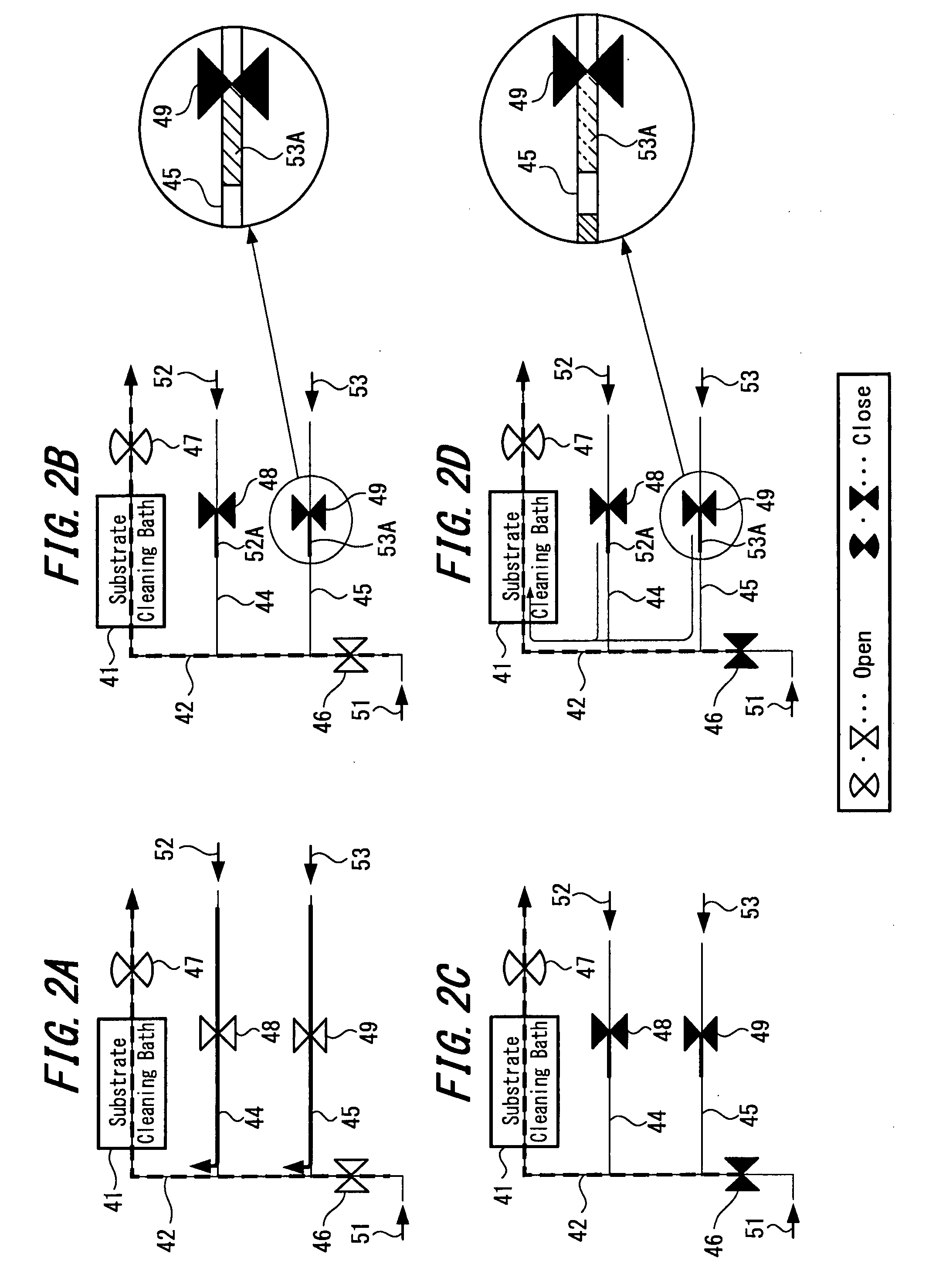

[0057]FIGS. 4A to 4E are respective diagrams showing those operation processes. It should be noted that open valves represent valves in the open state and that solid valves represent valves in the closed state in FIGS. 4A to 4E. Also, thick broken lines represent flows of supercritical CO2 and thick solid lines represent flows of additives and residuals thereof.

[0058]First, a wafer is accommodated and placed within the substrate cleaning bath 2. Next, as shown in FIG. 4A, cleaning processing is carried out. Specifically, the open / close valve 7 and the back-pressure valve 10 are opened so as to retain a supercritical state and a supercritical CO2 21 heated and pressurized is supplied to the substrate cleaning bath 2 through the main pipe 3. Fur...

second embodiment

[0064]Next, a cleaning method for cleaning an object using the supercritical cleaning apparatus 1 shown in FIG. 3 will be described with the operation processes.

[0065]FIGS. 5A to 5E are diagrams showing those operation processes. It should be noted that open valves represent valves in the open state and that solid valves represent valves in the closed state in FIGS. 5A to 5E. Also, thick broken lines represent flows of supercritical CO2 and thick solid lines represent flows of additives and residual additives.

[0066]First, a wafer is accommodated and placed within the substrate cleaning bath 2. Next, as shown in FIG. 5A, cleaning processing is carried out. Specifically, the open / close valve 7 and the back-pressure valve 10 are opened so as to retain a supercritical state and a supercritical CO2 21 heated and pressurized is supplied to the substrate cleaning bath 2 through the main pipe 3. Further, in the state in which the back-pressure valves 13 and 14 of the branch pipes 11 and 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com