Formed materials and strips used in fuel tanks and to prevent explosive reactions

a technology of formed materials and strips, which is applied in the direction of feeding apparatus, automatic control devices, containers, etc., can solve the problems of affecting the use of these materials, affecting the safety of workers, and being prone to deformation or significant inflexibility, etc., to achieve the effect of ensuring the porosity of materials, preventing explosive reactions, and simple way of manufacturing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

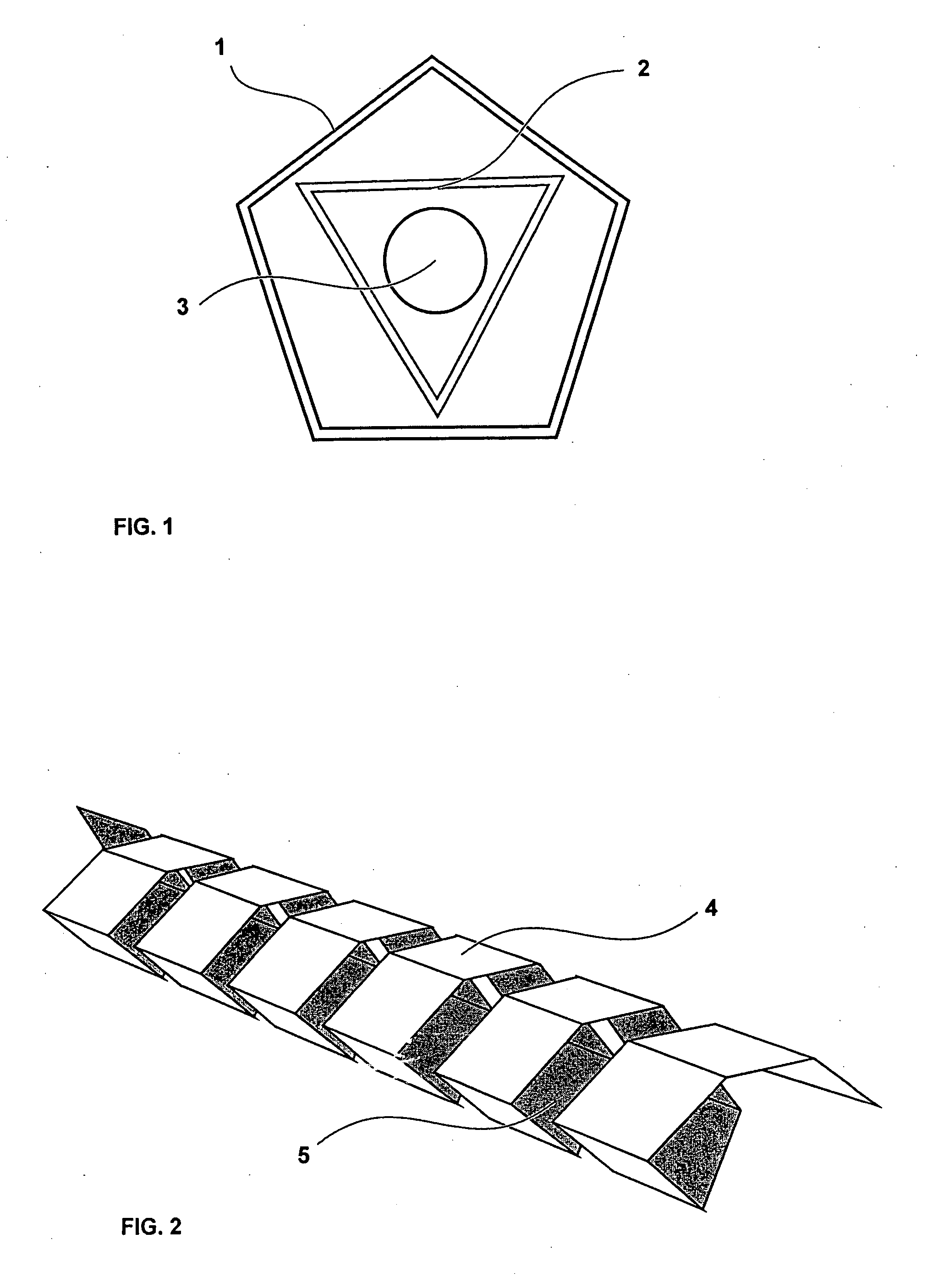

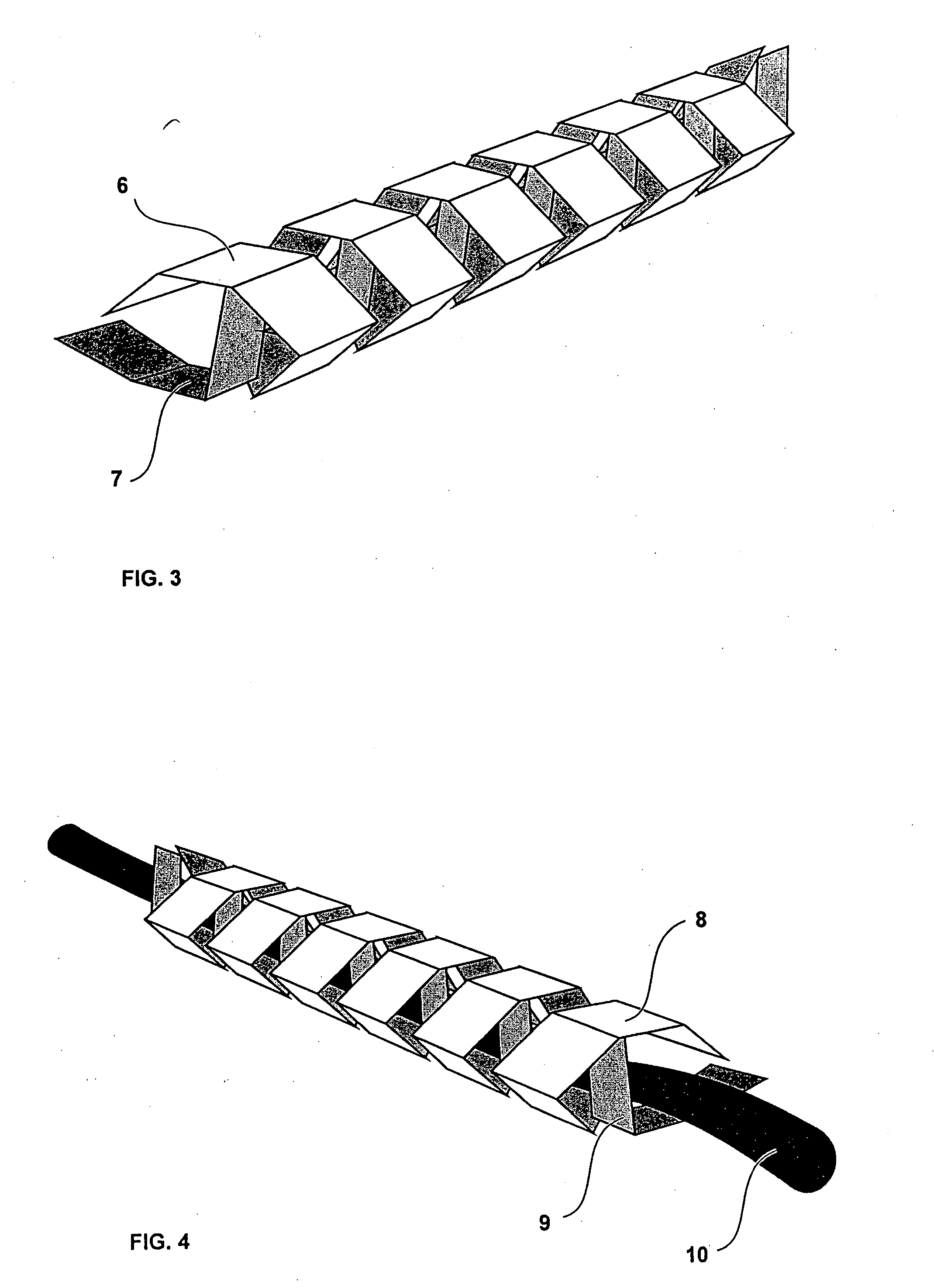

Image

Examples

Embodiment Construction

[0028] Each of the references (publication, article, web page, information source, or patent document, for example) referred to in this specification is hereby specifically incorporated herein by reference, in its entirety. Furthermore, each reference or any combination of references can be relied on and used, in whole or in part, to make, use, and test embodiments of the invention or specific examples described here. As this statement applies to each and every reference, document, or source of information, this specification will not repeat the incorporation by reference. This statement operates to effectively incorporate by reference in their entirety each and every reference (as defined above) listed or referred to in the specification.

[0029] In making and using aspects and embodiments of this invention, one skilled in the art may employ conventional techniques. Exemplary techniques are explained fully in the literature and are well known in the art. For example, one may rely on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap