Building modular and panel system and method of construction thereof

a technology of building modules and panels, applied in the direction of construction, building components, construction materials, etc., can solve the problems of limited use of conventional construction materials, inability to meet the needs of affordable housing, etc., to achieve the effect of rapid construction and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

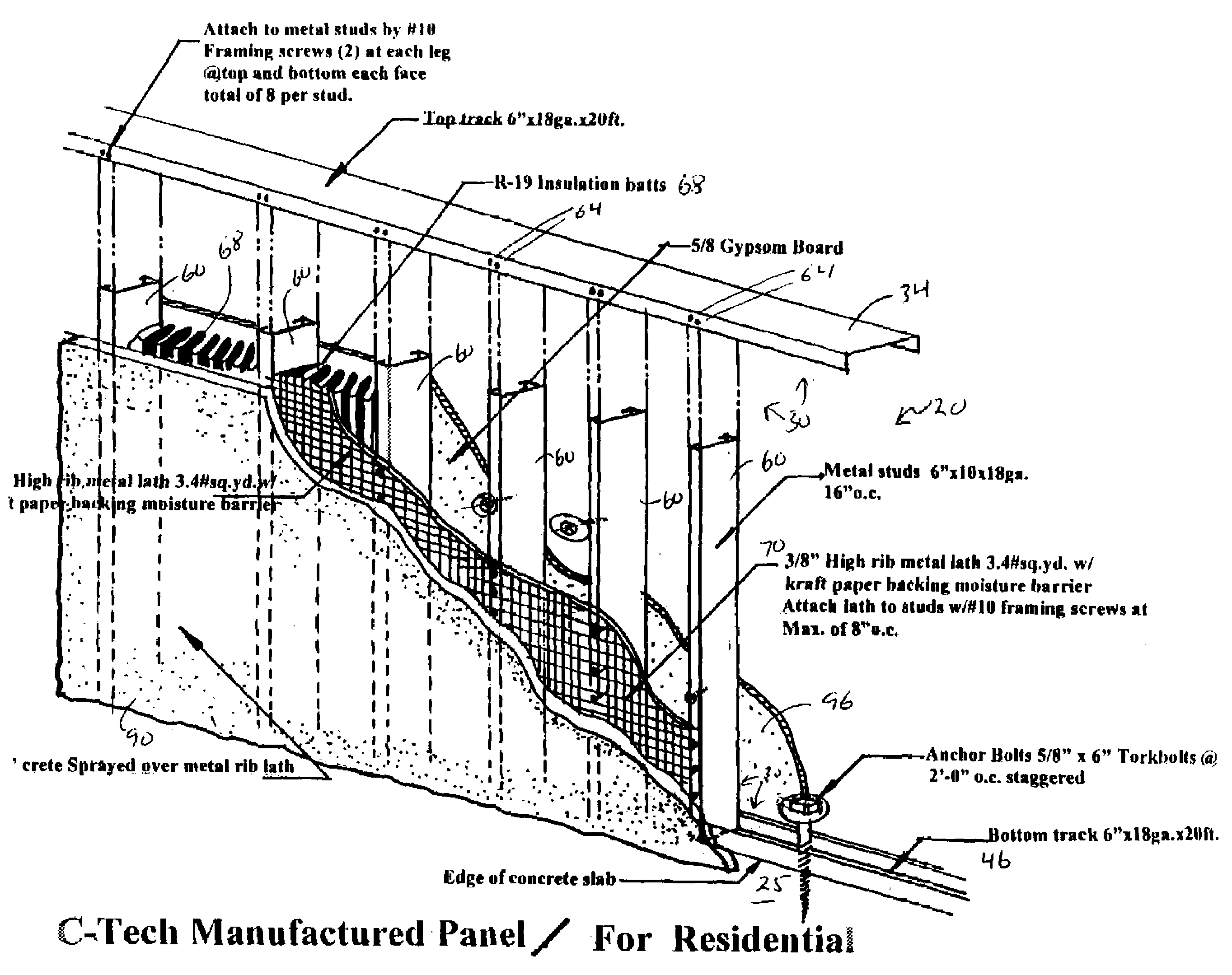

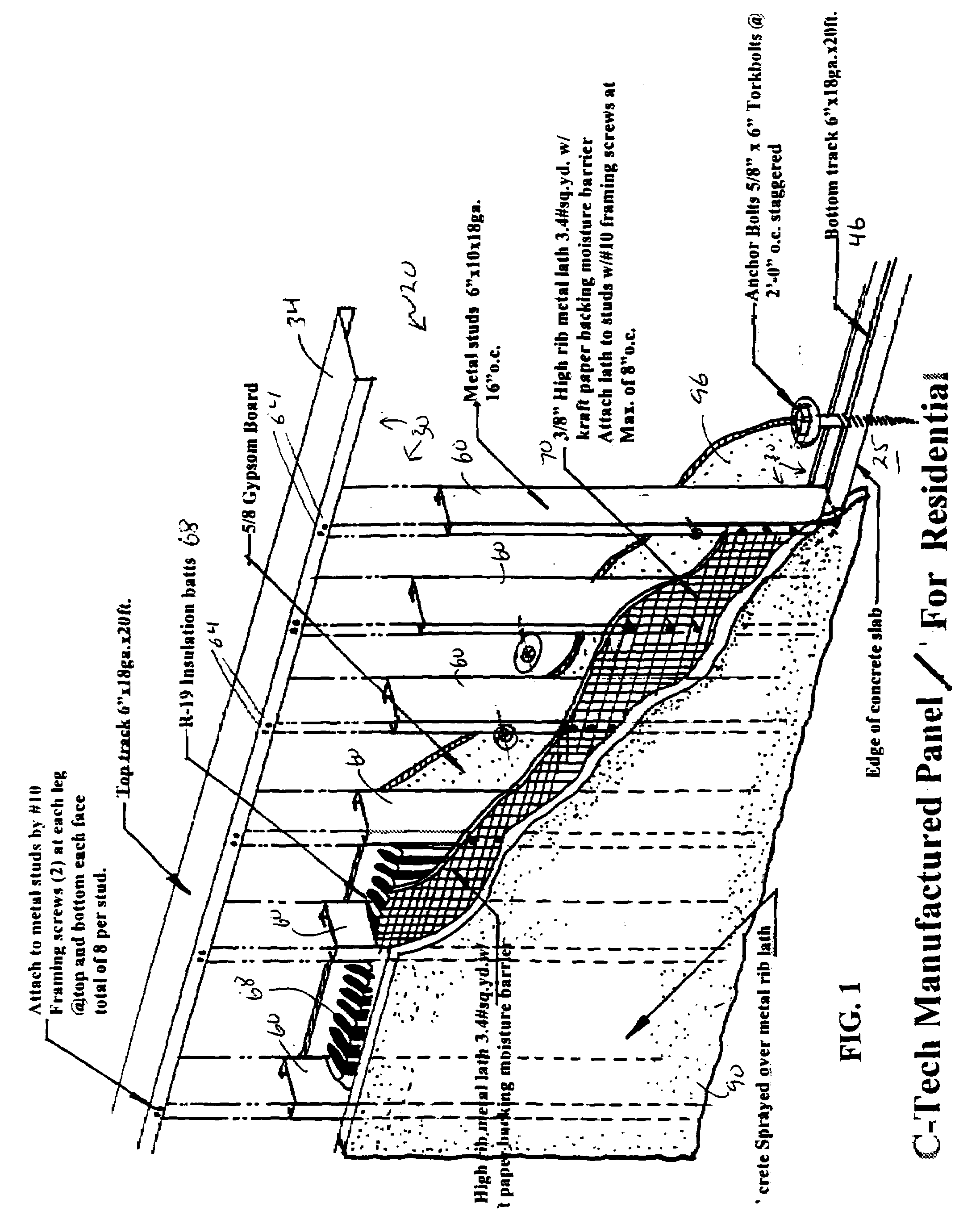

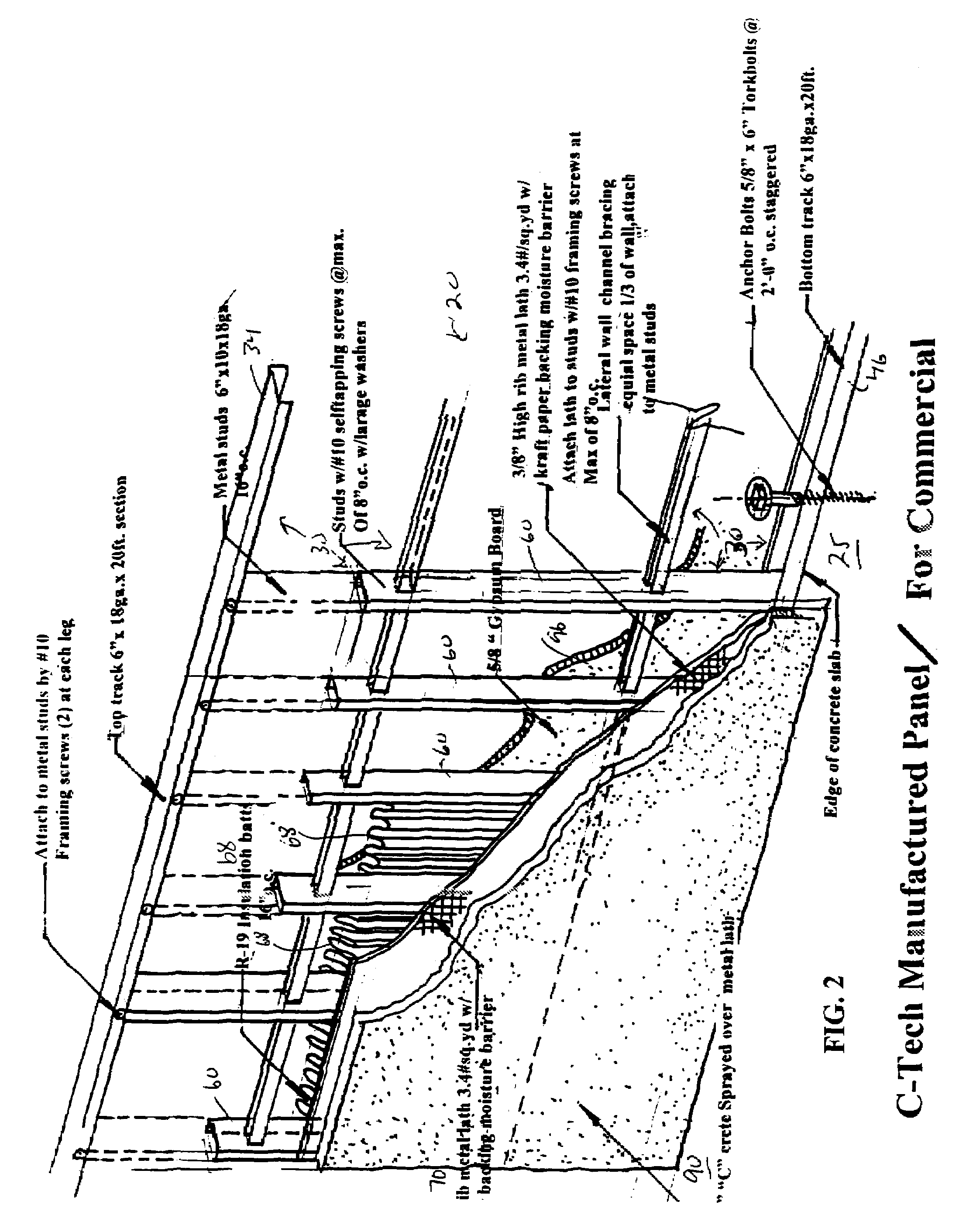

[0021]As seen in FIG. 1 a first embodiment for a manufactured panel is disclosed and generally designated as panel 20. Panel 20 generally comprises a frame assembly 30, a metal lath 70, an exterior finish 90 and an interior finish 96. Panel 20 can be preferably attached to a concrete slab 25, which has been previously been formed through conventional practices. FIG. 2 illustrates a second embodiment for the manufactured panel which is highly similar to the first embodiment, with the addition of lateral wall channel bracing provided, which can be preferably equally spaced up the wall and attached to the metal studs of the frame assembly 30. In one non-limiting embodiment, lateral bracing can be spaced out in ⅓rd lengths of the wall height, though such is not considered limiting. Though also not considered limiting, the lateral bracing can be preferably provided for commercial buildings and a panel 20 without bracing can be used for residential buildings. The below description for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com