Thin-film disposition apparatus

a technology of thin film and dissolution apparatus, which is applied in the field of thin film dissolution apparatus and chemical vapor deposition (cvd) apparatus, can solve the problem of not being able to provide an adequate supply of radicals into the film deposition process space, and achieve the effect of affecting performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention are described below with reference to the attached figures.

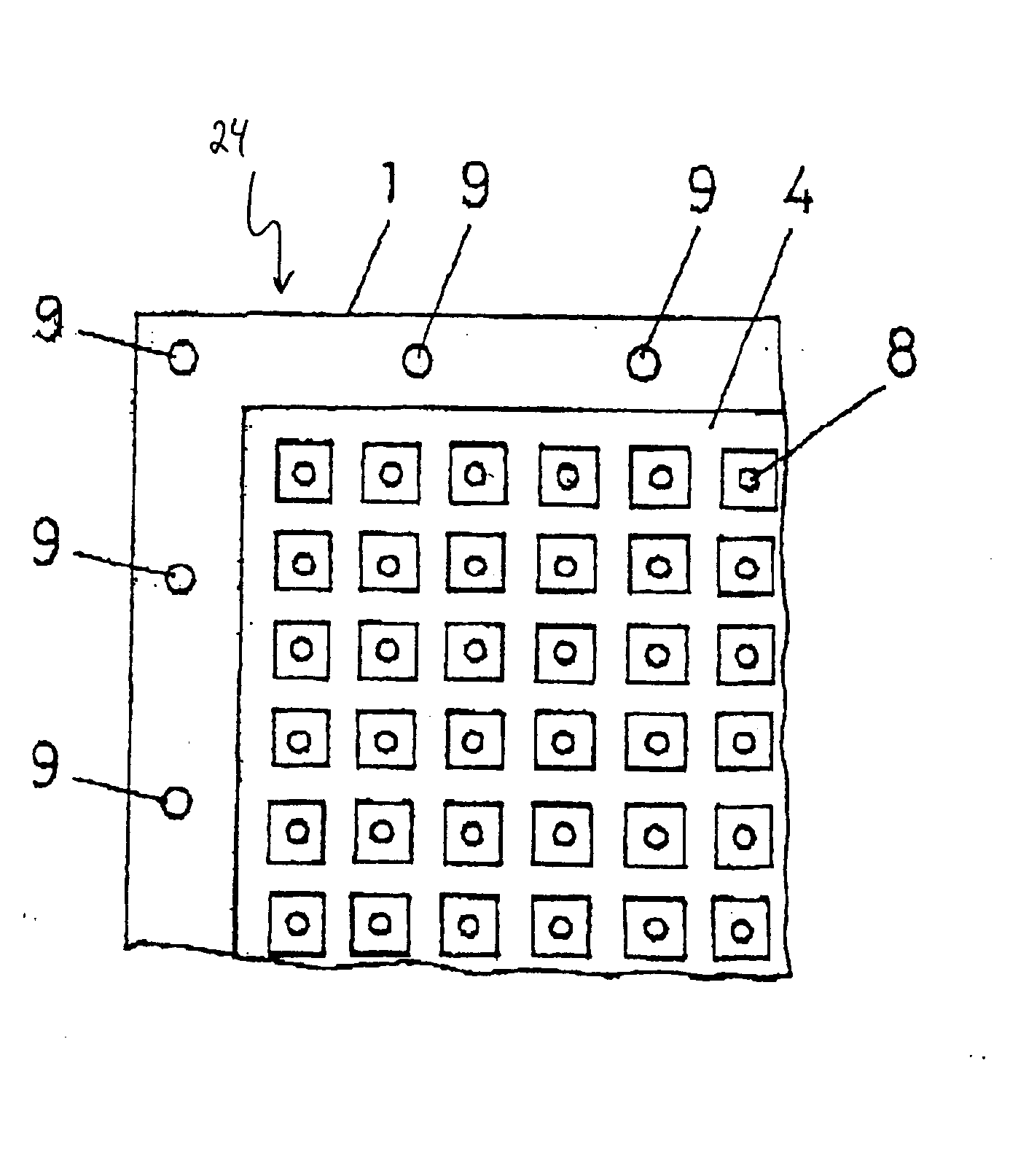

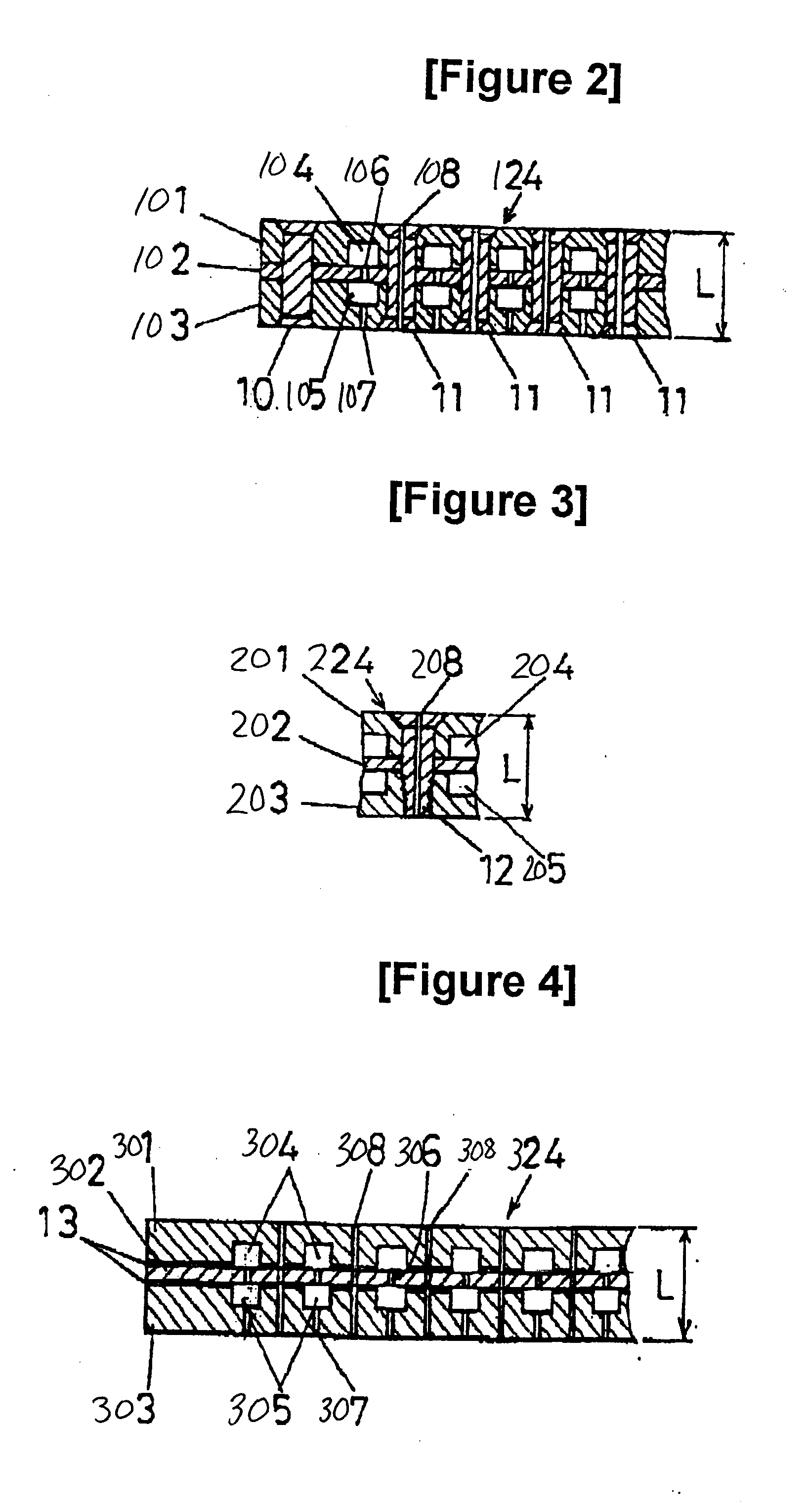

[0036]FIG. 2 is a cross-sectional view of a preferred embodiment of a dividing plate 124, which divides the vacuum reaction chamber of a thin-film deposition apparatus according to this invention (an example of which is shown in FIG. 5) into a plasma discharge space 25 and a film deposition space 26.

[0037] Dividing plate 124 is formed by fixing together a plurality of laminated plates (upper plate 101, intermediate diffusion plate 102, and gas discharge plate 103 on the film deposition side) by securely bonding them over the entire area of their interfacial surfaces or a large portion thereof (i.e., between upper plate 101 and intermediate diffusion plate 102, and between intermediate diffusion plate 102 and gas discharge plate 103 on the film deposition side) with a plurality of metal fixings, in this case by caulking with rivets 10,11. As used herein, the term interfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com