Process for Producing a Paper or Board and a Paper or Board Produced According to the Process

a technology of paper or board and process, which is applied in the field of process for producing paper or board and paper or board produced according to the process, can solve the problems of difficult adsorption of large amounts of starch to the fibers, poor ability to produce sufficient fiber bonding of paper or board, and cationically modified starches, etc., to achieve the effect of improving strength and not adversely affecting the bulk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

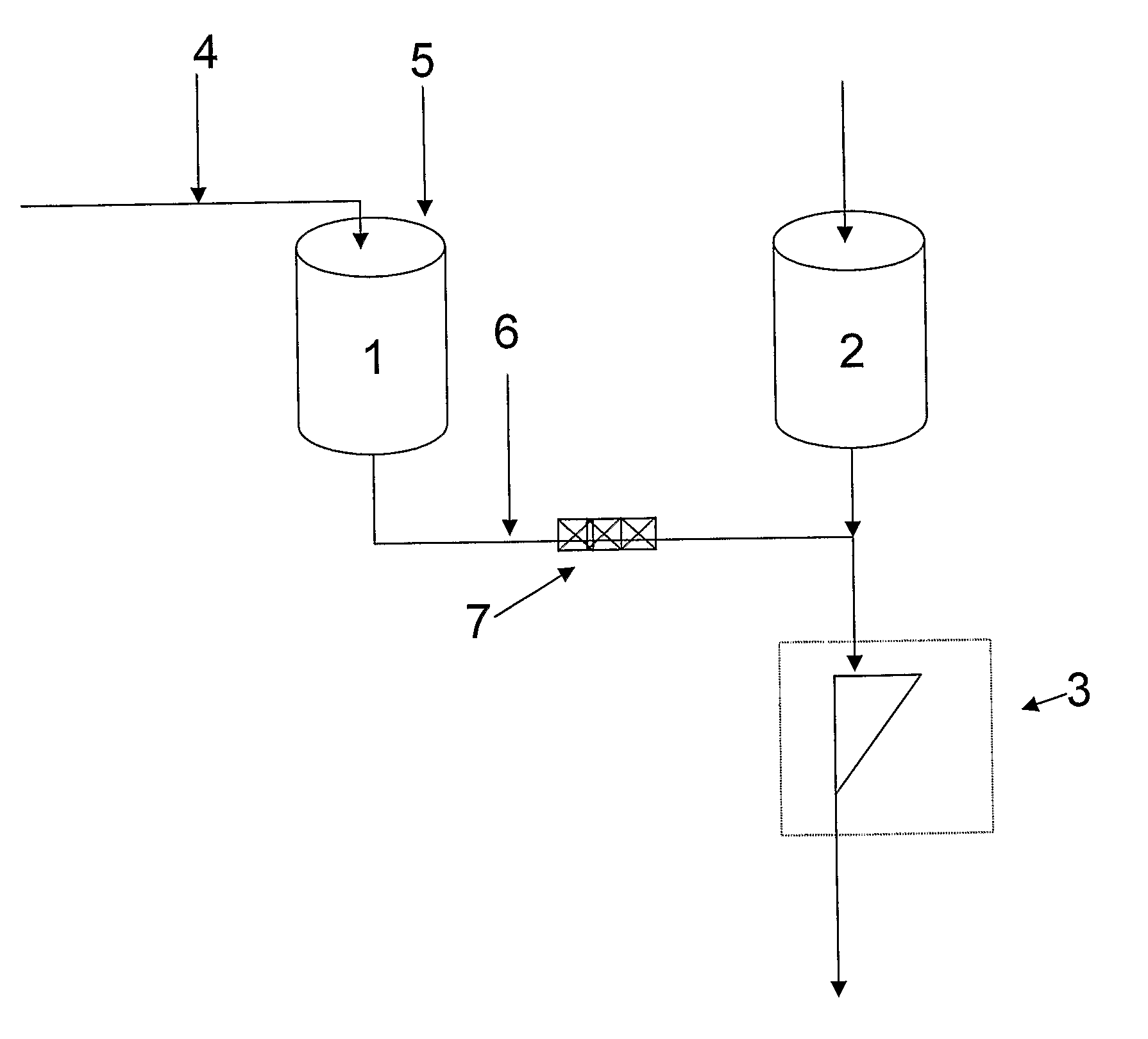

Method used

Image

Examples

example

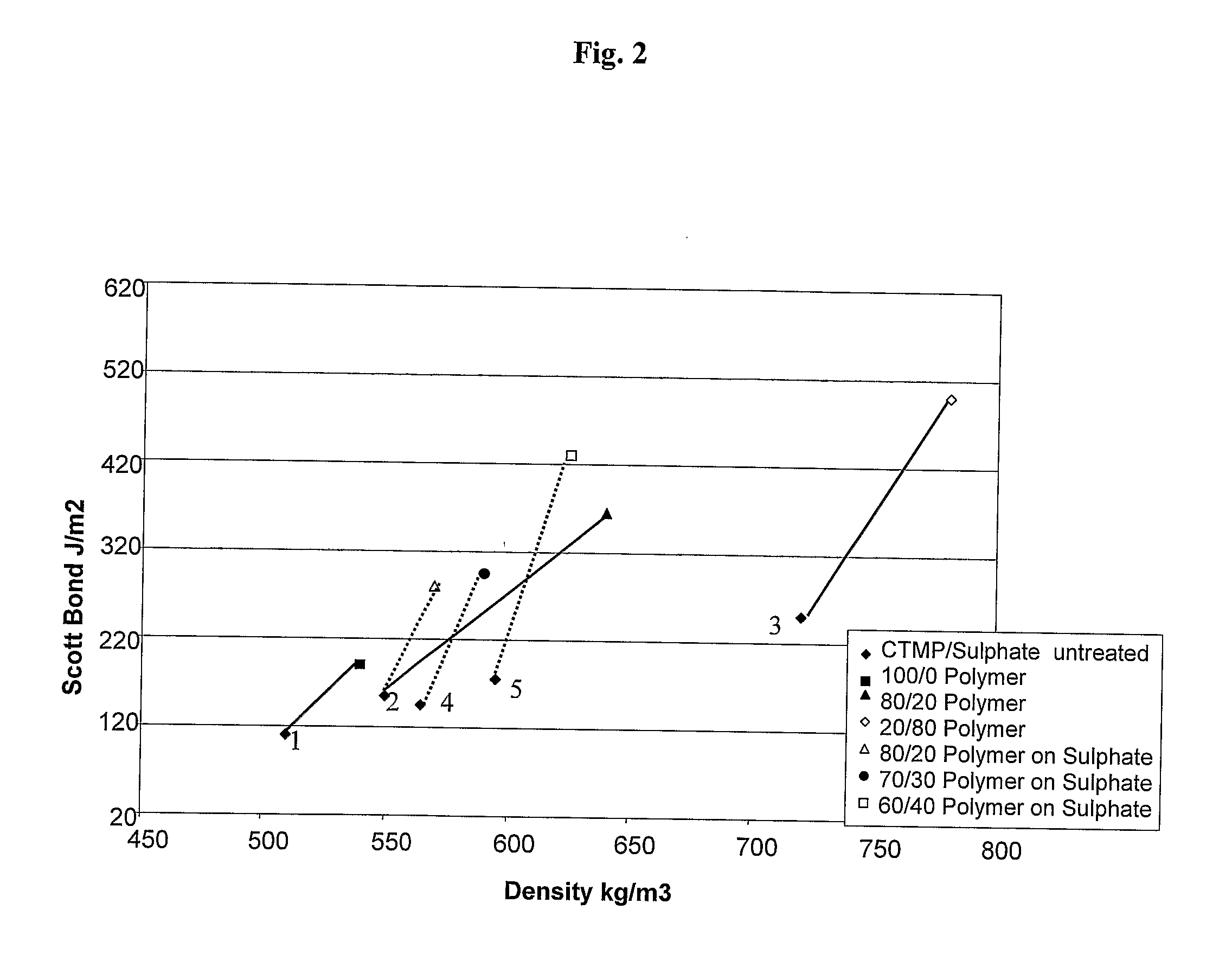

[0039] A board consisting of three layers was manufactured. The furnish forming the top and bottom layers of the board consisted of 50% hardwood pulp and 50% softwood pulp with a SR number of approximately 27.

[0040] The furnish forming the center ply of the board consisted of 55% CTMP and 45% of a mixture, hereinafter referred to as mixture portion, which mixture portion consisted of approximately 55% bleached softwood pulp, 15 % bleached hardwood pulp and 30% CTMP. A board consisting of CTMP and said mixture portion in the center ply represents a typical liquid packaging board.

[0041] Five different samples of board were manufactured. In two of the samples, the entire furnish used for the centre ply was treated with polymers in three consecutive steps (two steps with cationic starch additions with a step of CMC addition in between). Another two samples, were treated according to the invention, where only the mixture portion of the furnish (45% of the total furnish) was treated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com