Internal Drink Mix System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

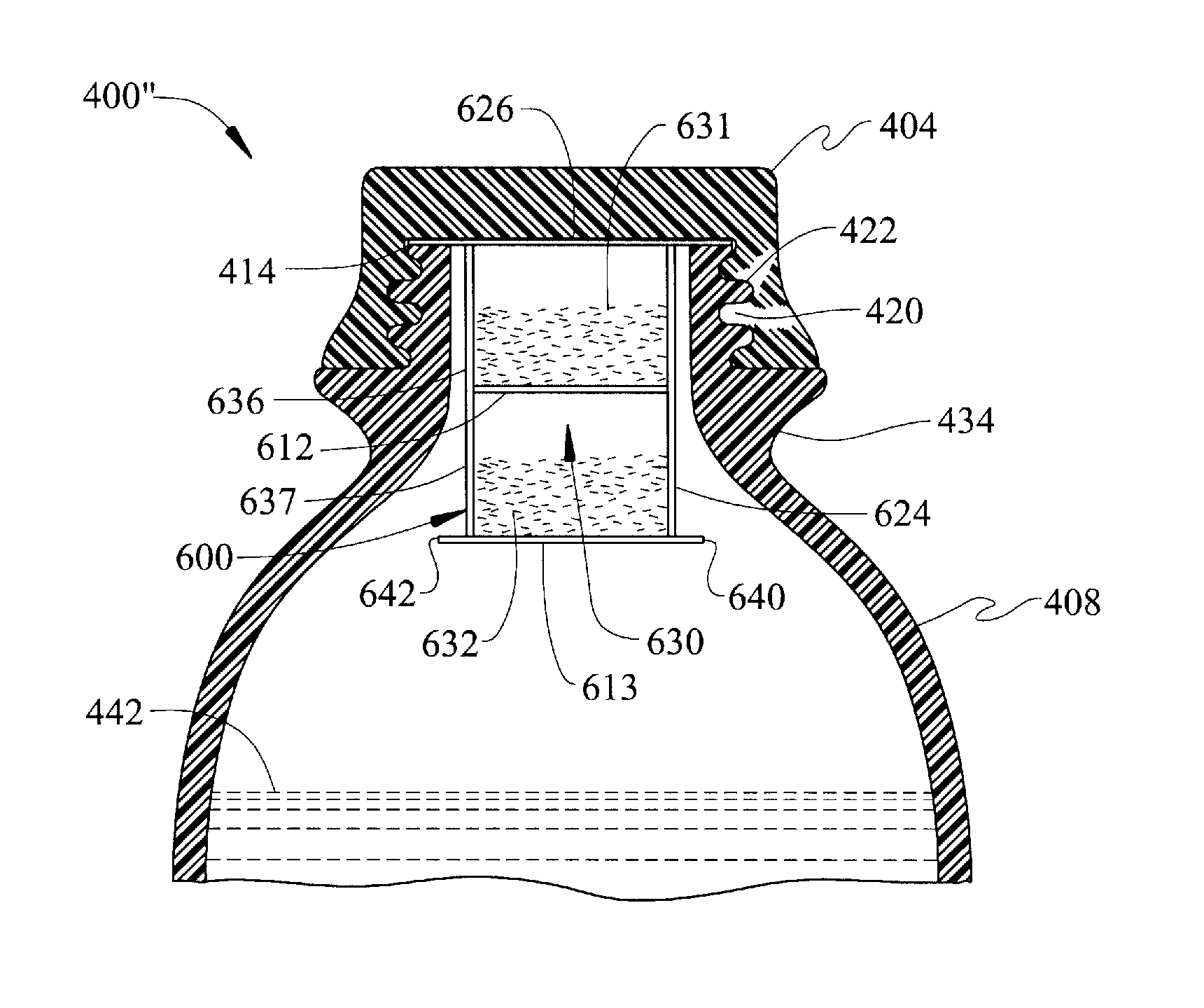

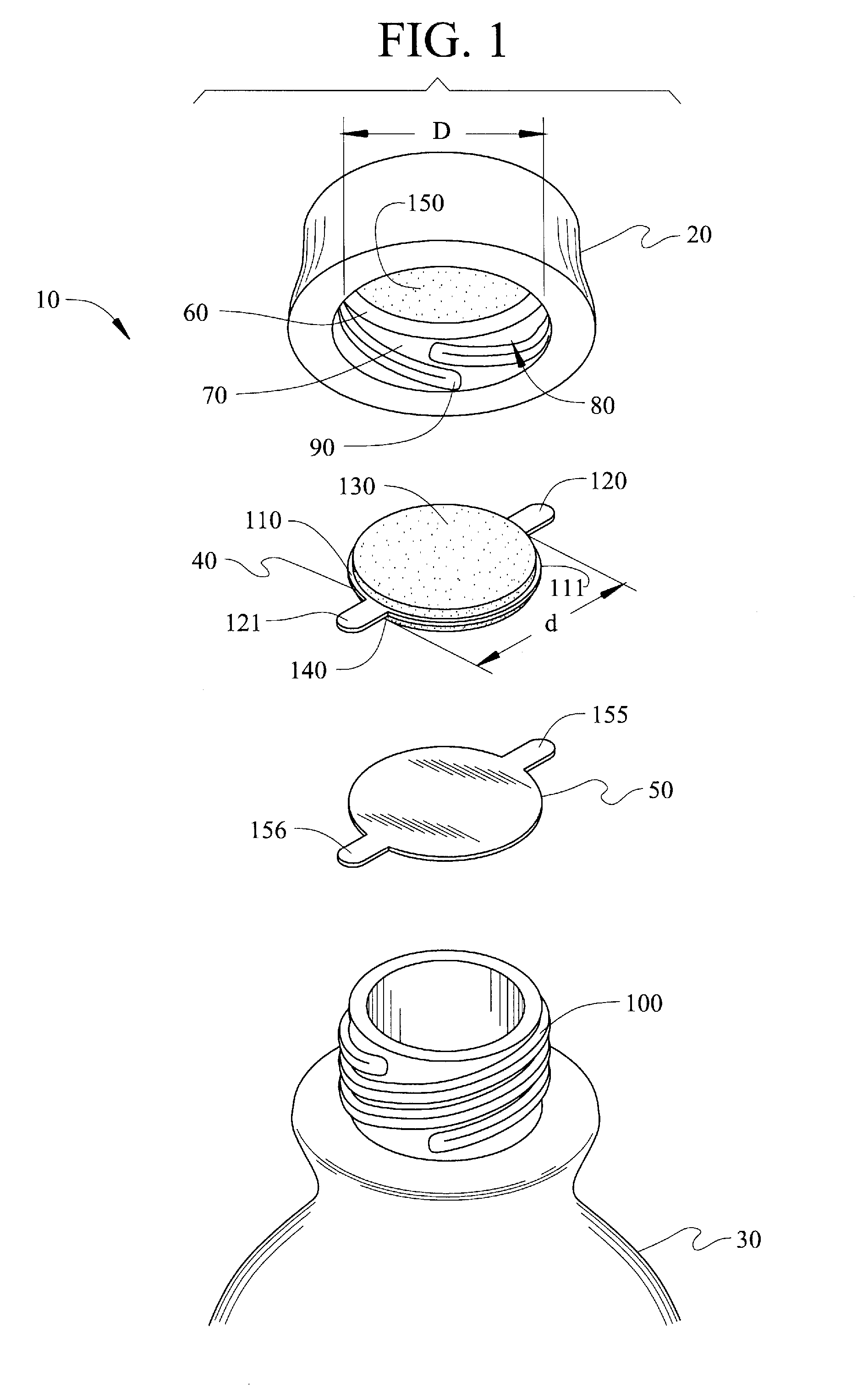

[0020] With initial reference to FIG. 1, a drink mix system 10 includes a bottle cap 20 used to close a bottle 30, an additive holder or disk 40 and a seal 50. Cap 20 includes an end wall 60 and a side wall 70 which collectively define an inner portion 80. Cap 20 can be any cap having threads 90 that extend from side wall 70 and are adapted to mate with threads 100 on bottle 30. Preferably, cap 20 and bottle 30 have standard structures and shapes; thus allowing bottles and caps currently on the market to be used with little or no modification in conjunction with the present invention. Disk 40 includes first and second sides 110 and 111, and preferably also includes first and second diametrically opposed tabs 120 and 121. Disk 40 is formed from cardboard, plastic, foam or any other thin flexible material capable of supporting a beverage or drink additive. A first drink additive 130 is coated on first side 110 of disk 40. Preferably, for a greater range of additives, a second drink ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com