Laminate pressure containing body for a well tool

a well tool and containing body technology, applied in the direction of well accessories, drilling casings, drilling pipes, etc., can solve the problems of stress corrosion cracking, material damage to fluids produced by hpht wells, and the well structure becomes more difficult, and achieves the effect of higher yield valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

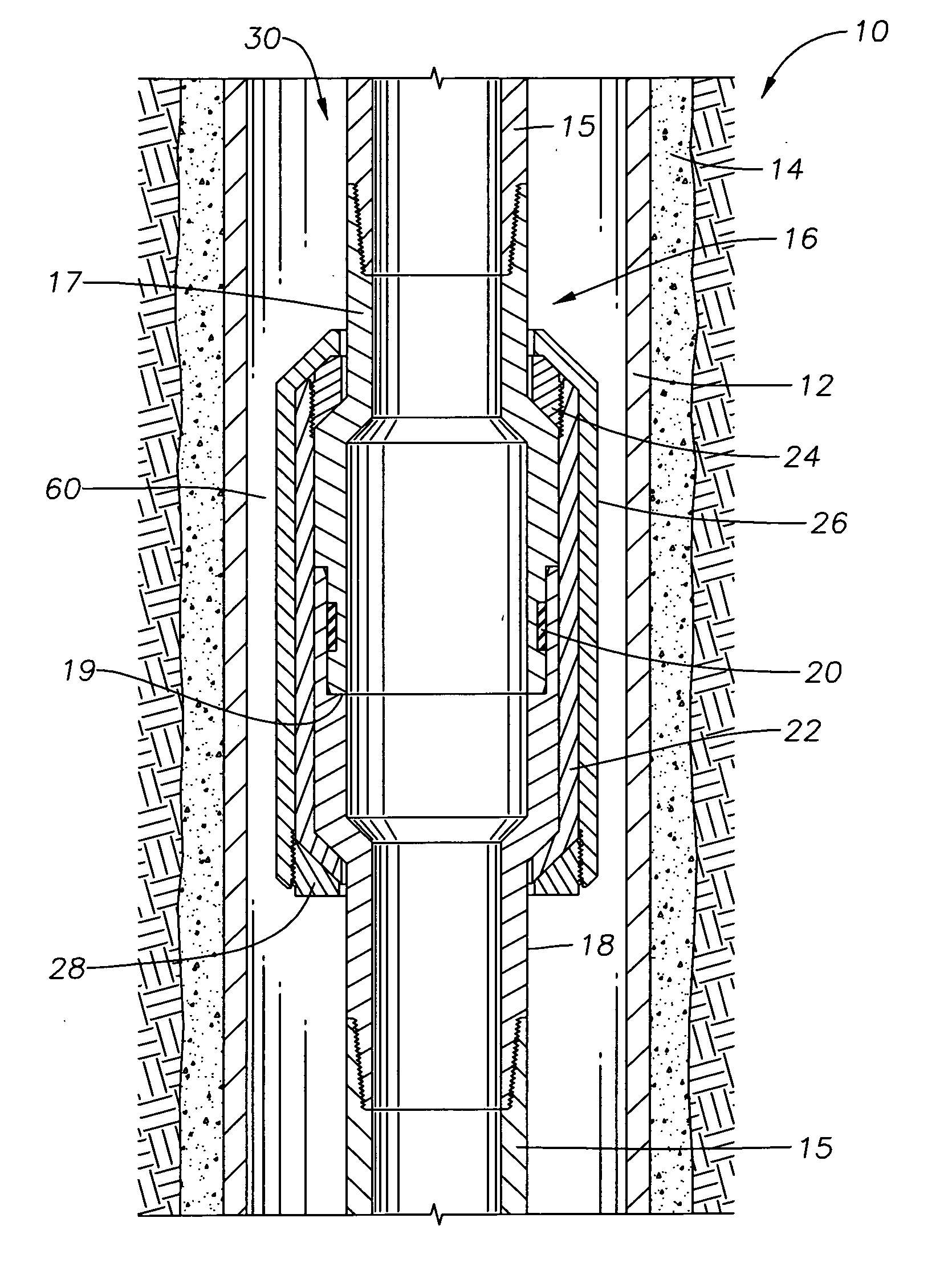

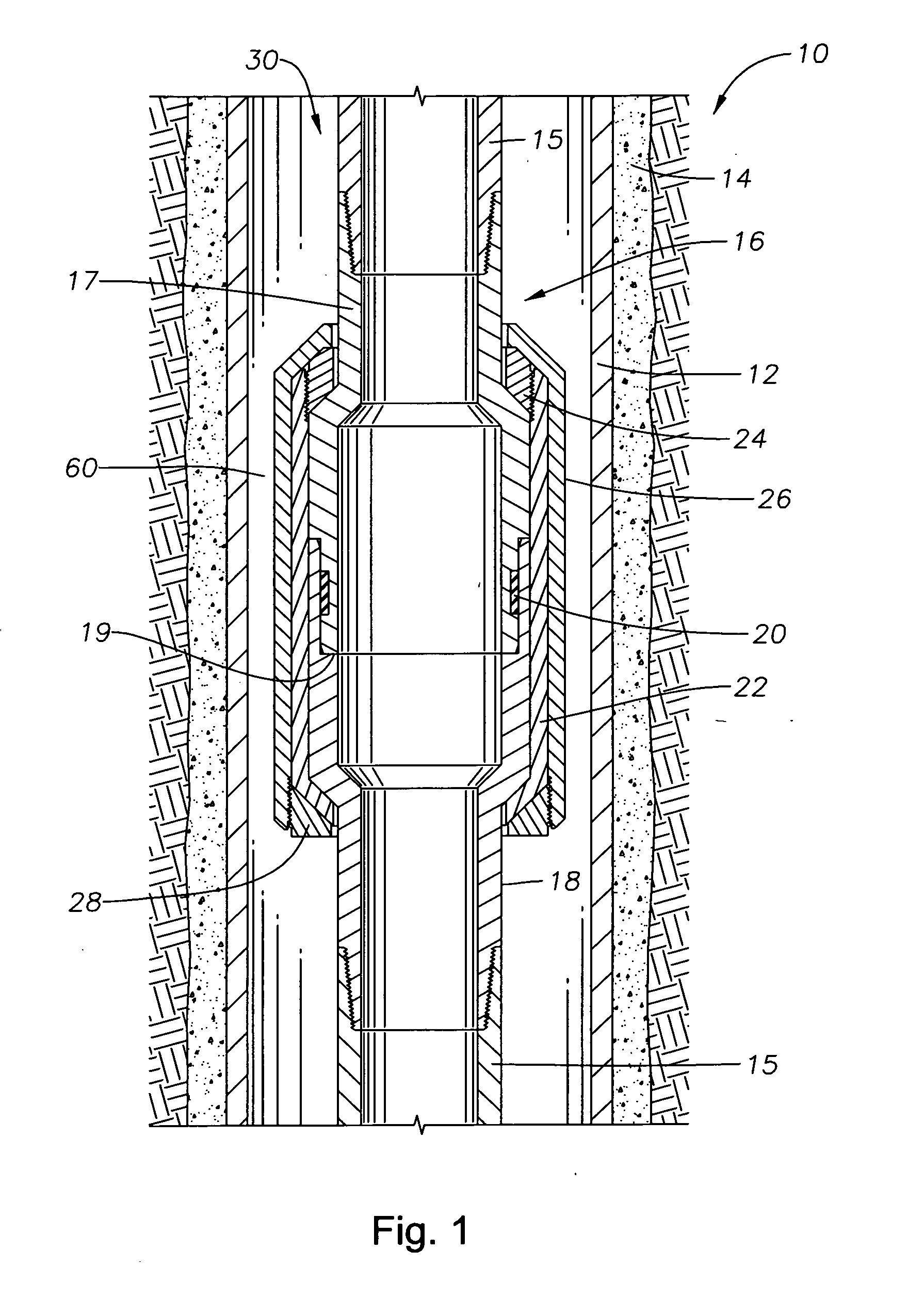

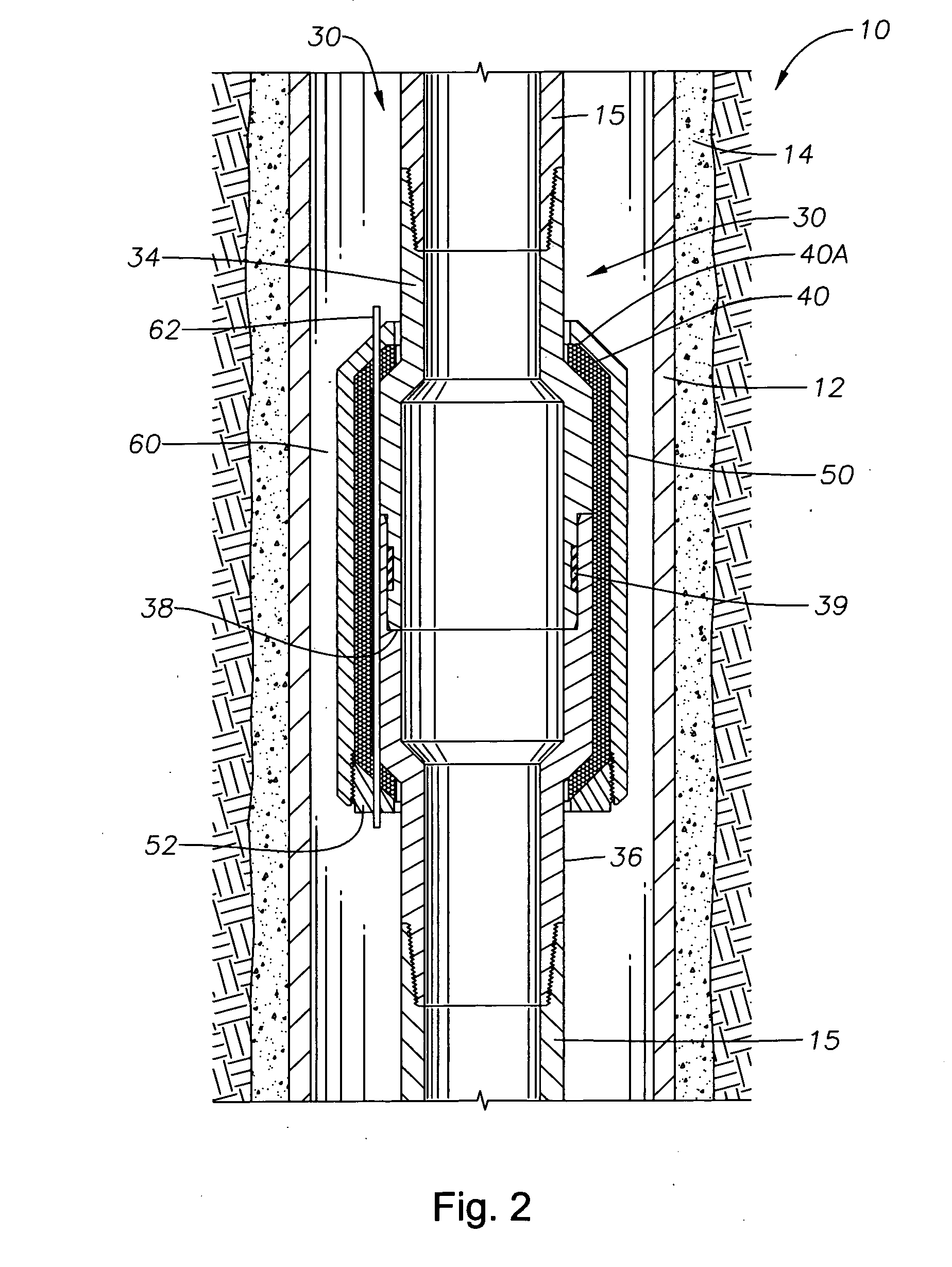

[0015]The description herein applies the invention primarily to a genre of well tools known as well completion tools or equipment. Generally, the invention applies to equipment in a well for which less wall thickness is needed. This would include: pressure-containing equipment in a well that must, because of its inherent design, have greater outside diameter than the tubing in a well if it is to maintain the same flow area as the tubing, and tubulars or connectors for tubulars that preferably are reduced in external diameter with the same internal diameter. This includes, but is not limited to, devices that are normally larger diameter than the tubing, such as subsurface safety valves, packers, flow control devices (e.g., sliding sleeves), tubing hangers, on-off attachments, and gas lift or instrument mandrels as well as equipment normally the same diameter as tubulars that would preferably be smaller in diameter, as least in some segments of a well, such as production tubing, liner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com