Thermoelectric Refrigerating Modules

a refrigeration module and thermoelectric technology, applied in the field of refrigeration, can solve the problems of reducing the refrigeration effect, affecting the refrigerating efficiency of the refrigerating piece, and unable to operate efficiently and reasonably, so as to improve the refrigerating effect of the tec refrigeration module, and improve the refrigerating efficiency of the tec refrigerating piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail in connection with the following preferred embodiments with reference to the companying drawings.

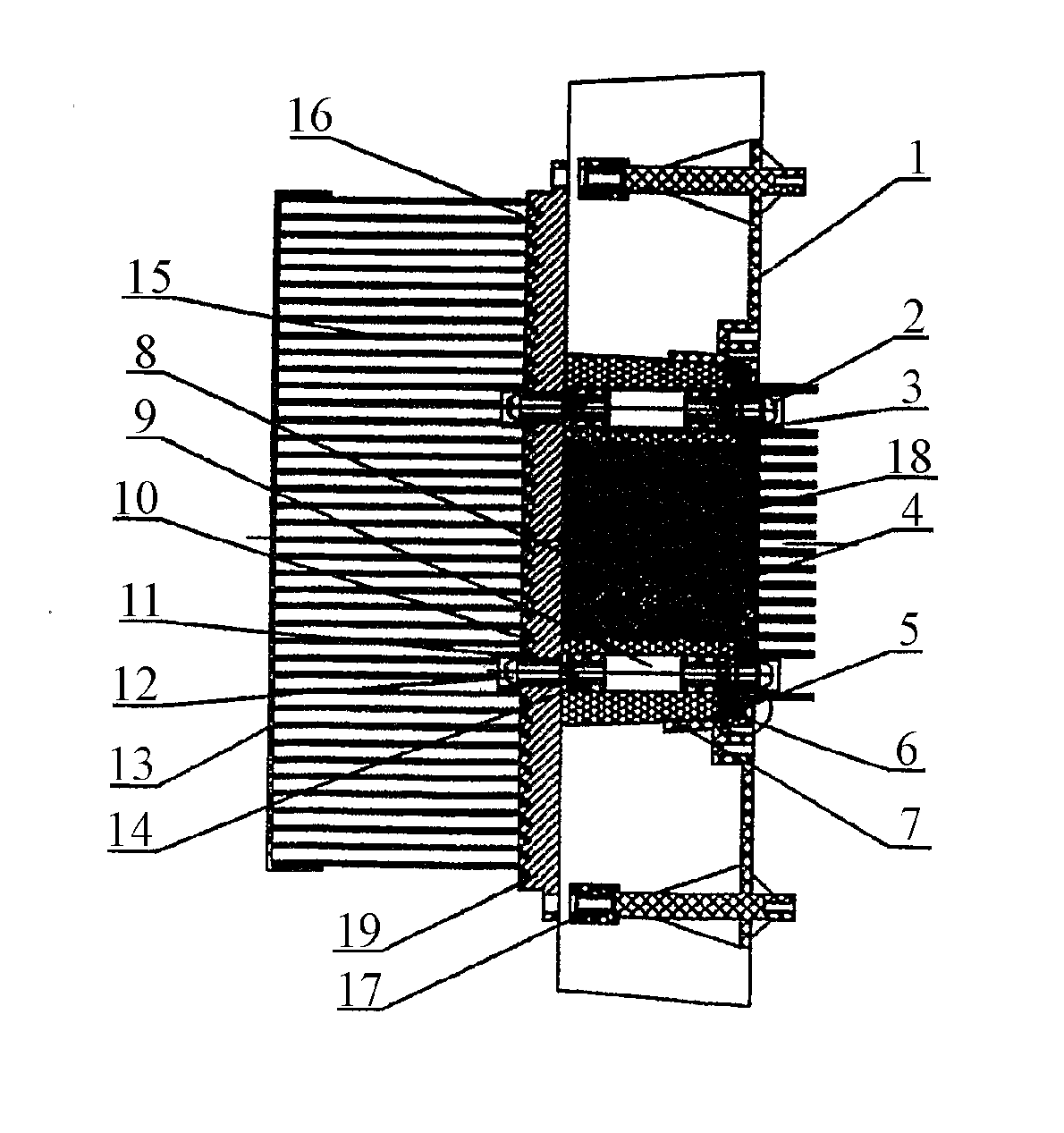

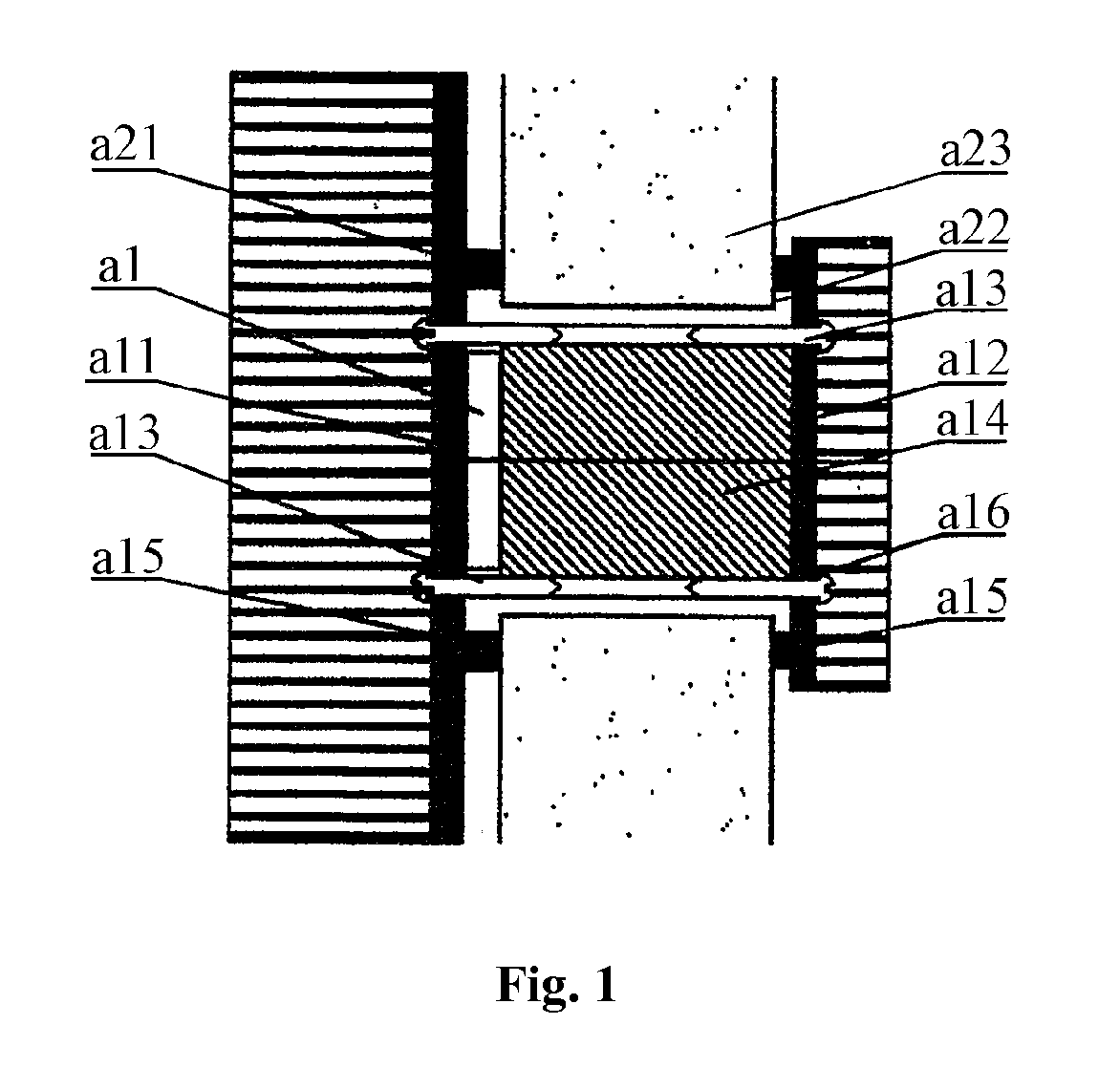

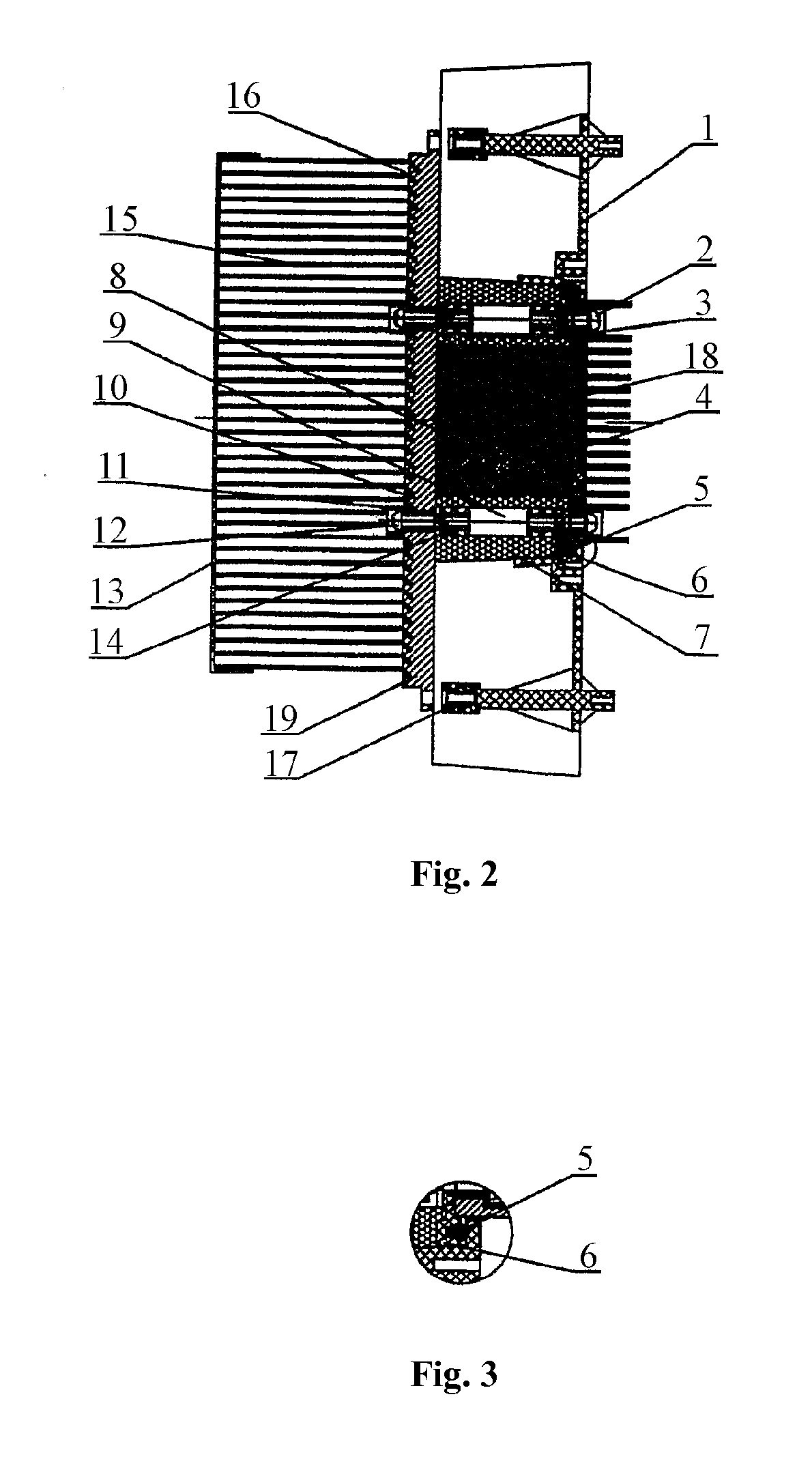

[0028]FIGS. 2, 3 and 4 show an embodiment according to the present invention. As shown in FIG. 2, a refrigeration module of the embodiment comprises a TEC refrigeration piece 8 having a top surface and a bottom surface, a radiator 16 and a cold eliminator 18 including a brick body 4 with a bottom surface. The top surface of the TEC refrigeration piece 8 is adhered to the bottom surface of the brick body 4, and the bottom surface of the TEC refrigeration piece 8 is closely contacted to the cold eliminator 18. The radiator 16 comprises a base 10, a plurality of radiating fins 15 each having an end portion and a top portion, and an air guide plate 13 with a U-shaped profile. The base 10 provides a plurality of recesses 19 in parallel. The end portions of the plurality of radiating fins 15 are inserted into the respective recesses so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com