Axial turbine

a technology of axial turbine and axial shaft, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of reducing the output power of the stage, the inability to provide a plurality of balance holes in a circumferential direction, etc., to prevent the decrease in the output power of the stage, the effect of preventing the interference of the blowout flow and improving the efficiency of the turbine stag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

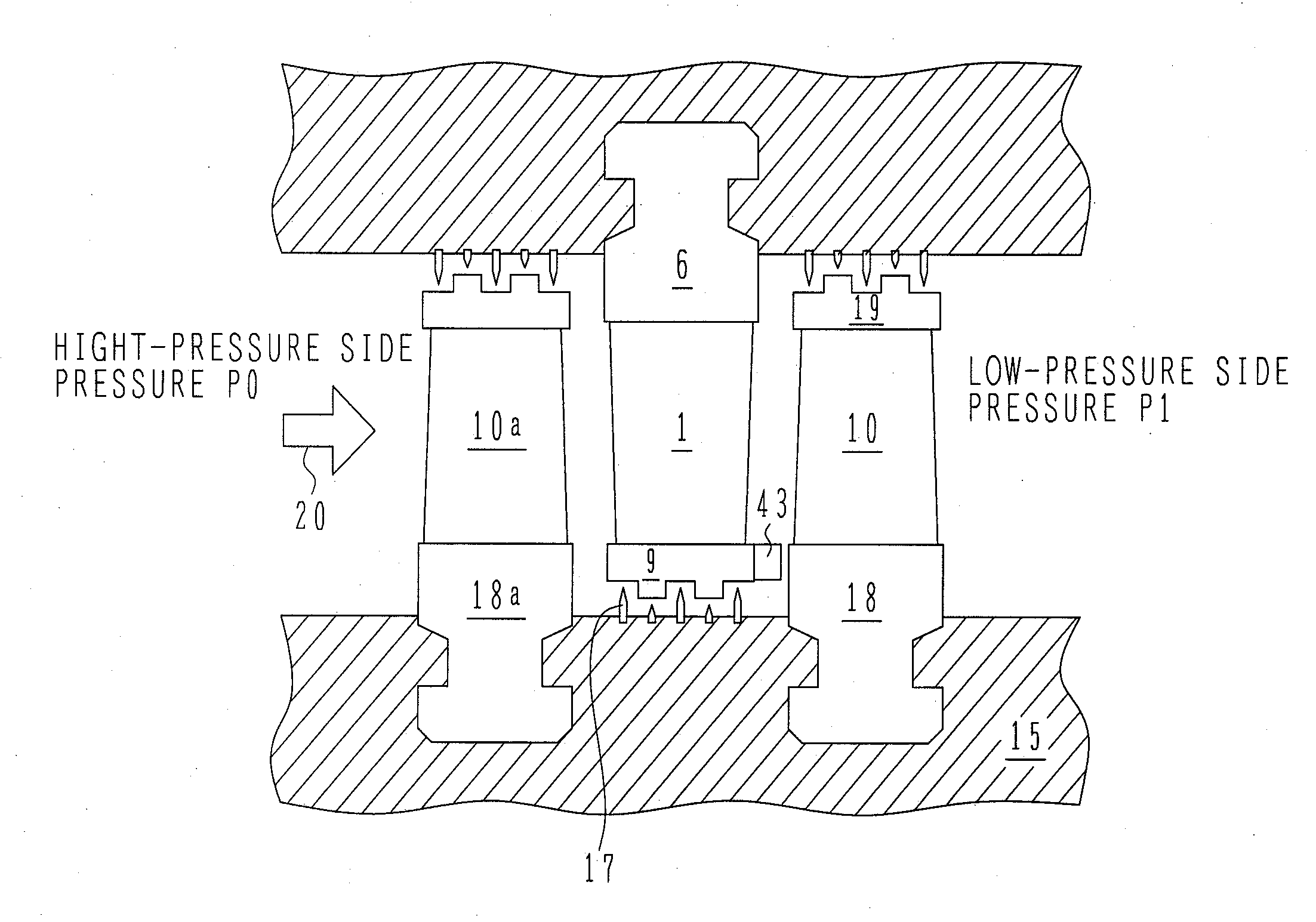

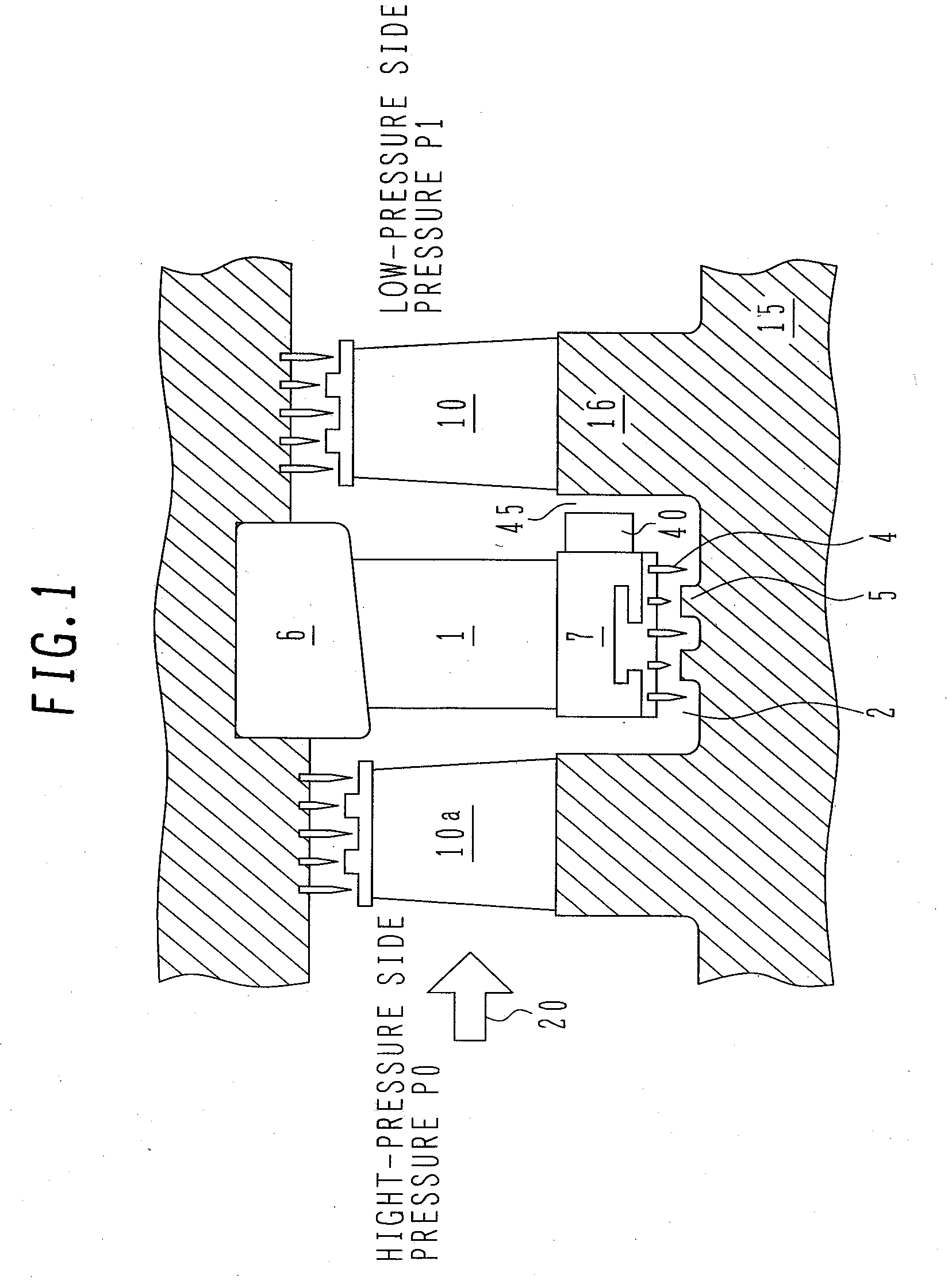

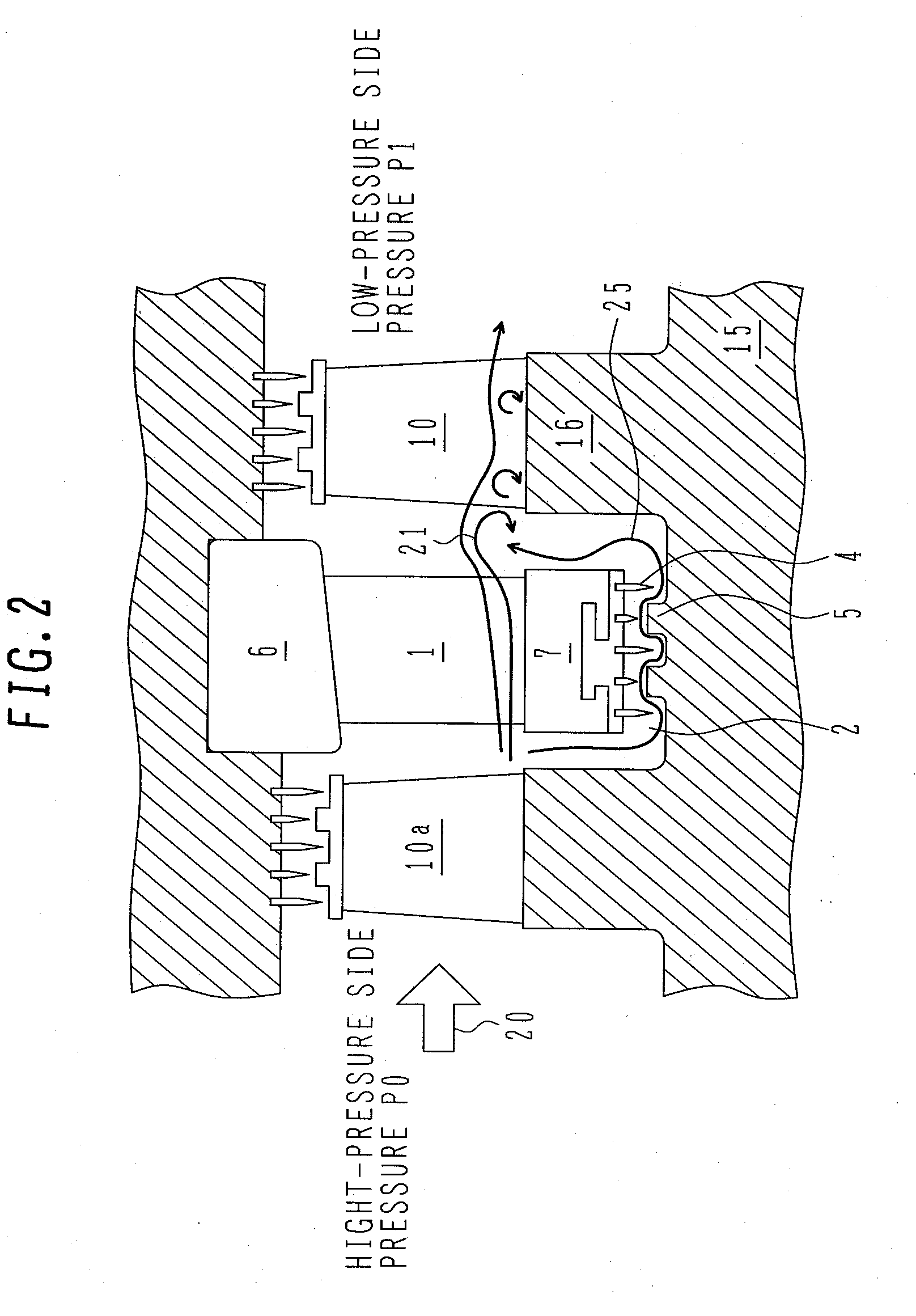

[0022]Hereunder, an axial turbine having a turbine stage according to a first embodiment of the present invention will be described by using the accompanying drawings.

[0023]A sectional view of the turbine stage of the present invention is shown in FIG. 1. As shown therein, the turbine stage is provided between a high-pressure side P0 and a low-pressure side P1, and includes stator blades 1 fixed to an outer circumferential diaphragm 6 and an inner circumferential diaphragm 7, and moving blades 10 provided on a rotor 15 that rotates. In case of a turbine having a plurality of turbine stages, moving blades 10a of another stage exist at an upstream side of the stator blades 1.

[0024]A main flow of steam 20 is induced by a differential pressure P0-P1, and the flow 20 is speeded up by the stator blades 1 and deflected in a circumferential direction thereof. The flow to which the circumferential velocity component has been assigned by the stator blades 1 gives kinetic energy to the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com