Method of adjusting coefficient of restitution of face of golf club head

a golf club and coefficient technology, applied in the field of making golf clubs, can solve the problems of increasing the cost, shifting the center of gravity of the head, and the cost of manufacturing such faces is much higher, and achieves the effect of reducing the cost of manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

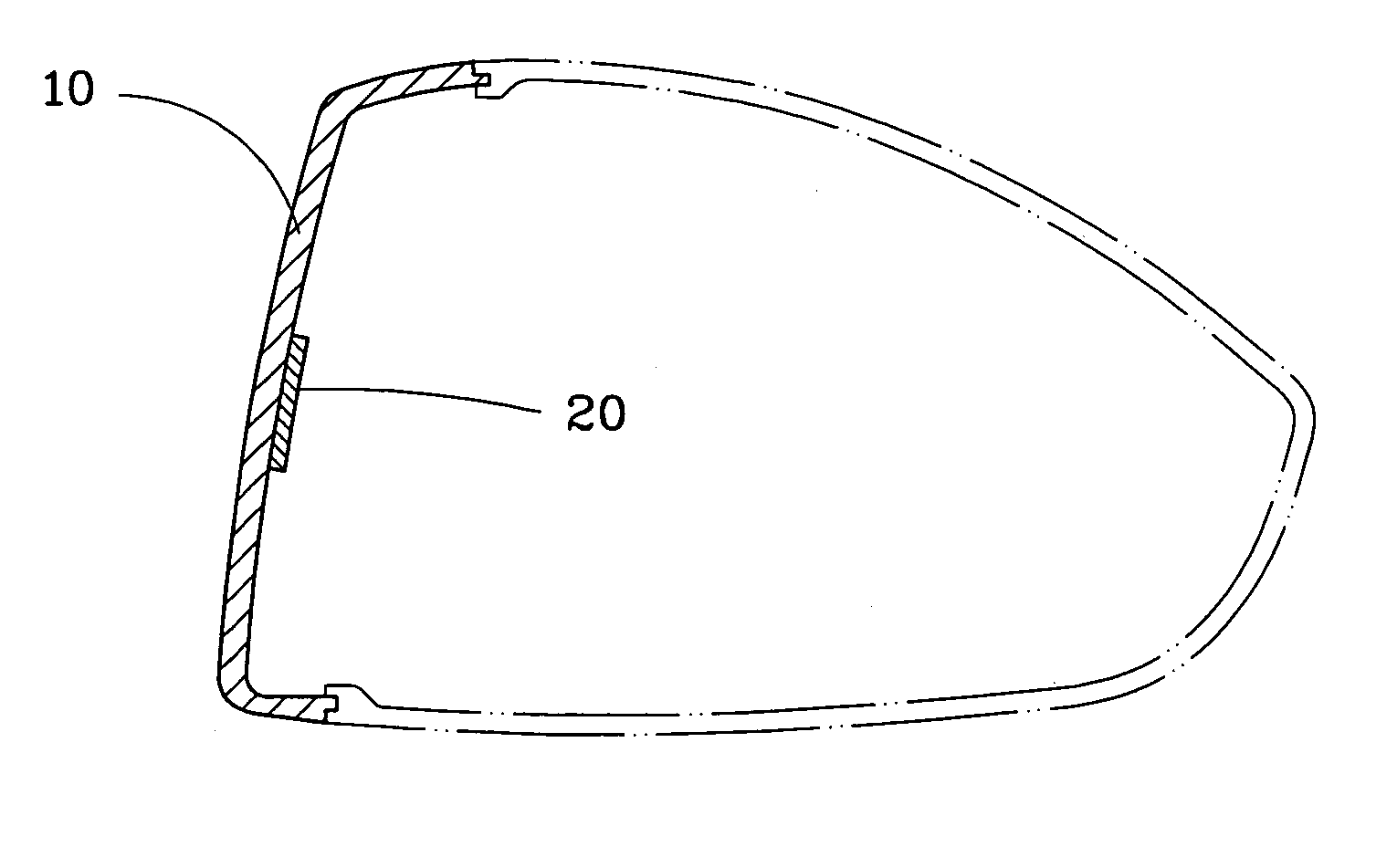

[0011]As shown in FIG. 1, a face 10 of a golf club head may be made of metal and made by casting, forging or punching. In the present invention, the face 10 is made of titanium alloy, more preferred βTi TVC, with a thickness about 2.5 mm and a hardness of HRC42°. An assistant device 20 is made of βTi 15-333 with a thickness about 1.5 mm and a hardness of HRC28°. The assistant device 20 is pressed on a center of a back side of the face 10 and spun in a high speed. The spinning of the assistant device 20 generates heat, and the heat welds the assistant device 20 and the face 10 together, so called friction welding, to form a face thicker at center and thinner at margin. The thickness of the center of the face is about 4 mm that may reduce the ROC.

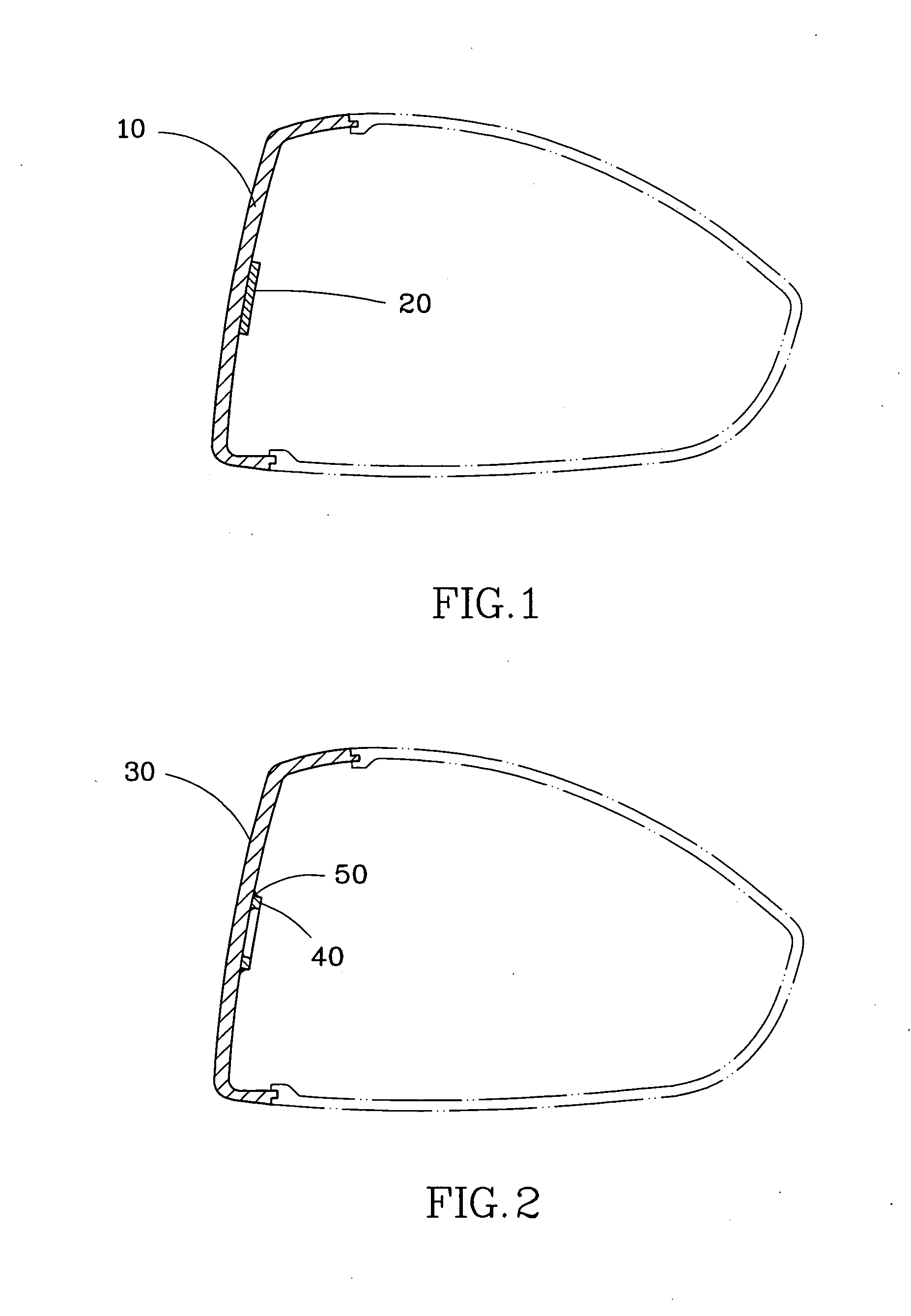

[0012]As shown in FIG. 2, the second preferred embodiment provides a face 30 made of 6-4 titanium and an annular assistant device 40, which is made of 6-4 titanium also, fixed at a center of a back of the face 30 by friction welding. It has g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com