Catalyst heating control method of parallel type hybrid vehicle

a technology of parallel-type hybrid vehicles and control strategies, which is applied in the direction of electrical control, machine/engine, exhaust treatment electric control, etc., can solve the problems of reducing affecting the efficiency of the emission control device, so as to reduce the ignition efficiency of the engine, rapidly warm the catalyst, and efficiently purify a large amount of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Reference will now be made in detail to the preferred embodiment of the present invention. The embodiments are described below so as to explain the present invention by referring to the attached drawing.

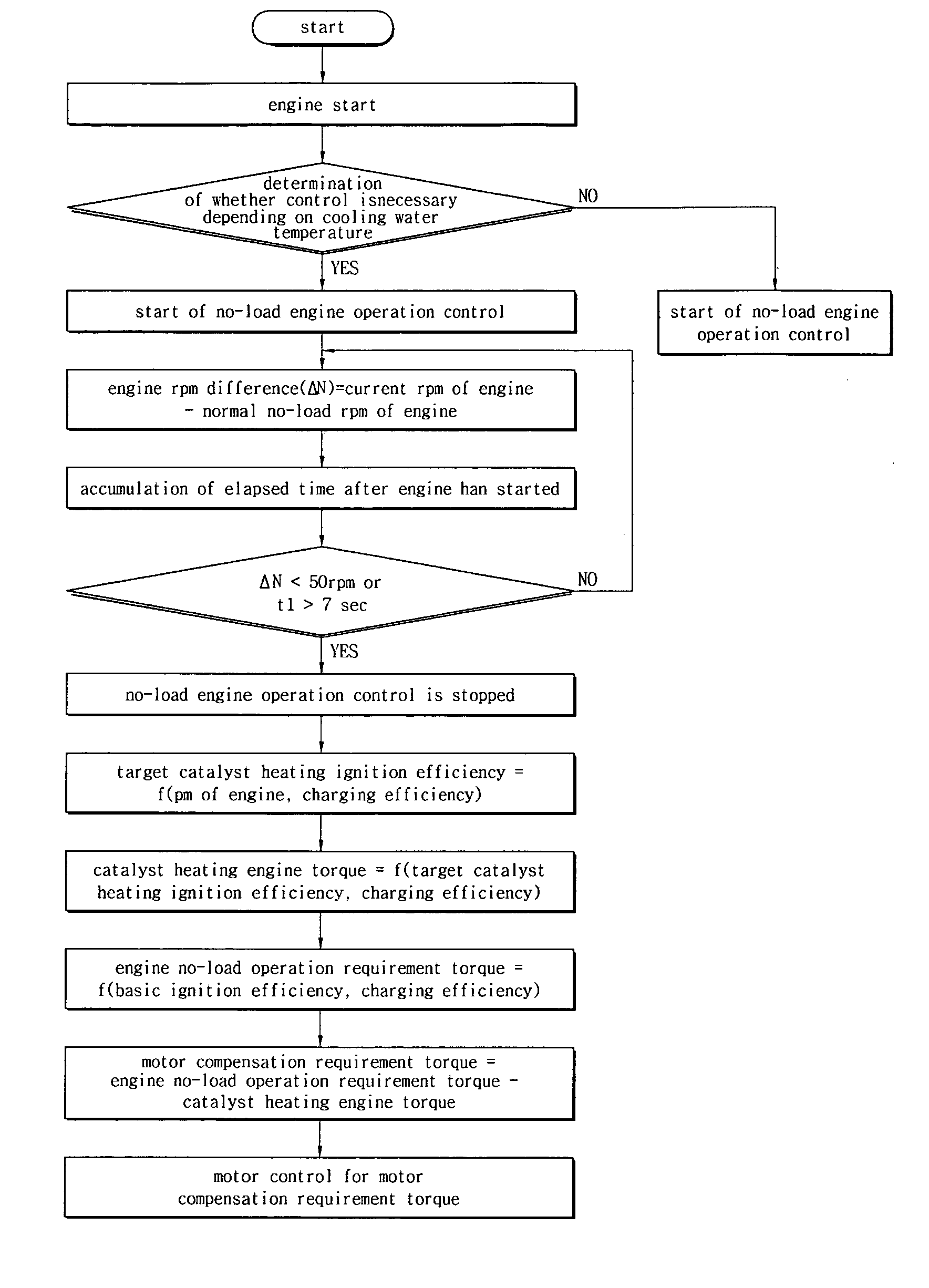

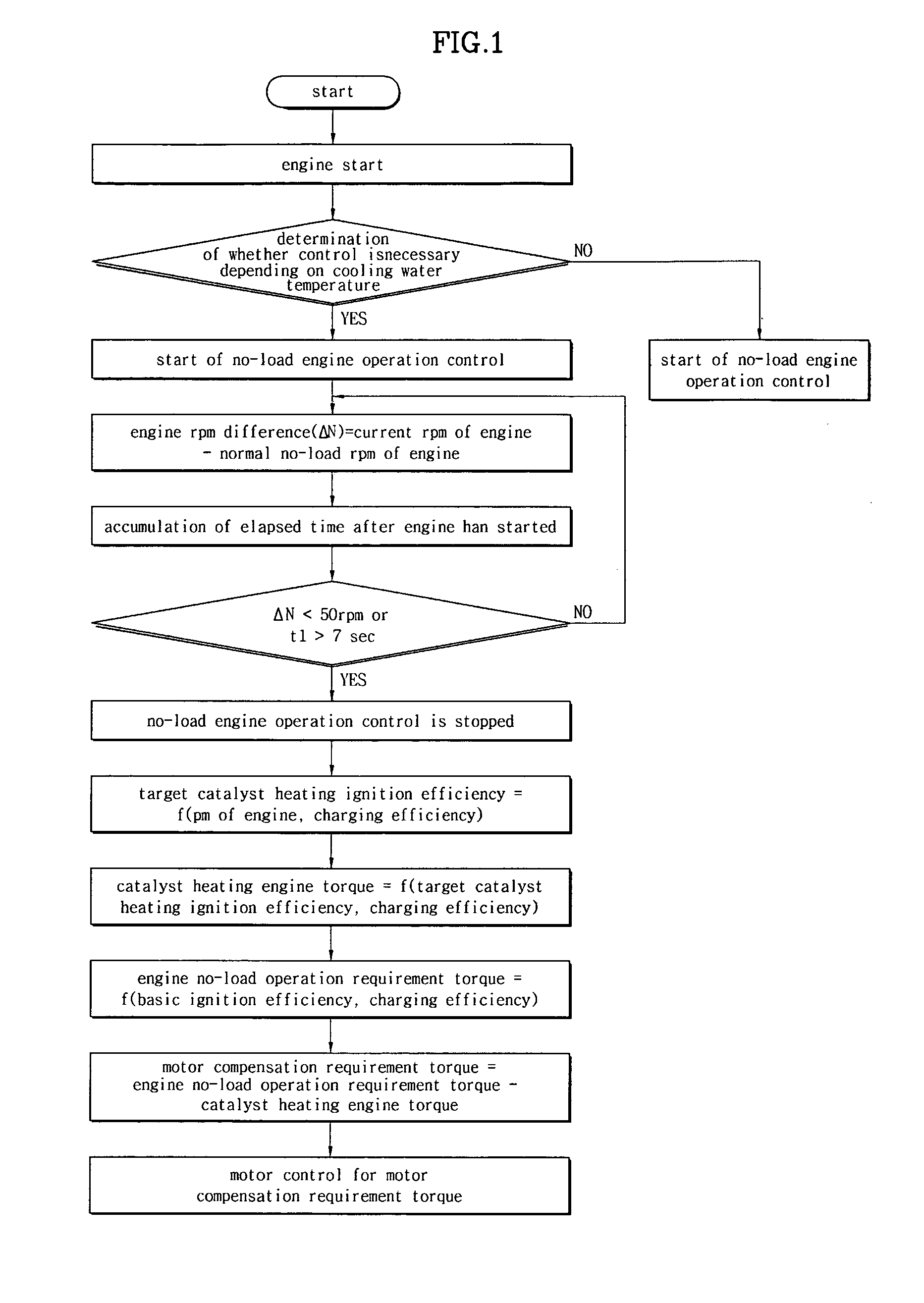

[0025]Referring to FIG. 1, in a preferred embodiment of the present invention, after an engine is started, whether a catalyst heating control is required is determined. This determination depends on the temperature of cooling water of the engine just after the engine is started. The result of the determination in turn determines whether the catalyst heating control operation is conducted or not.

[0026]The reason for this is that the catalyst heating control is unnecessary in case where the engine is not cold-started but was running a short time ago.

[0027]After the catalyst heating control determination step, a typical no-load operation control of the engine is conducted.

[0028]That is, it is preferable that because the catalyst heating control determination step must be conducted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com