Heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

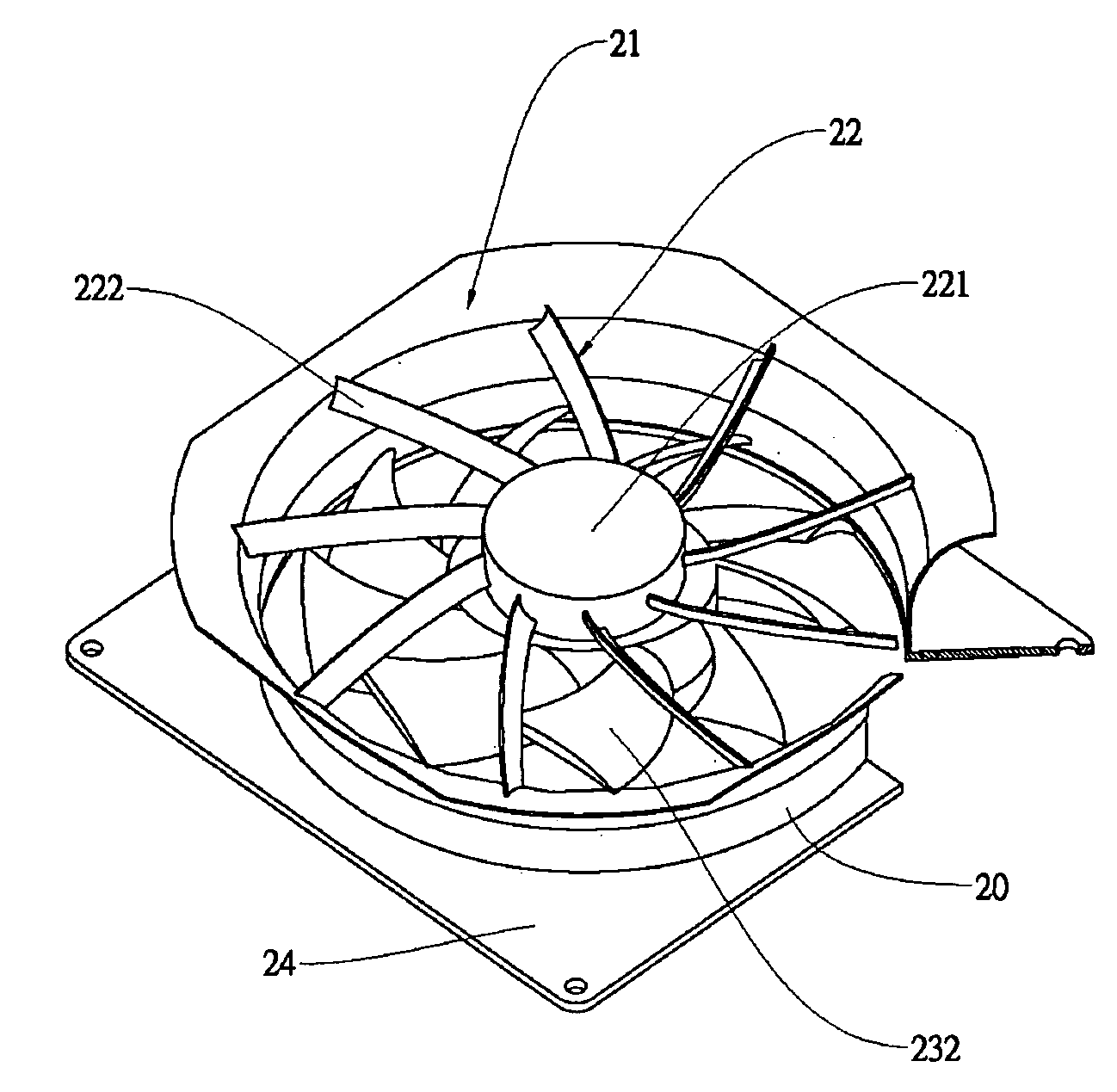

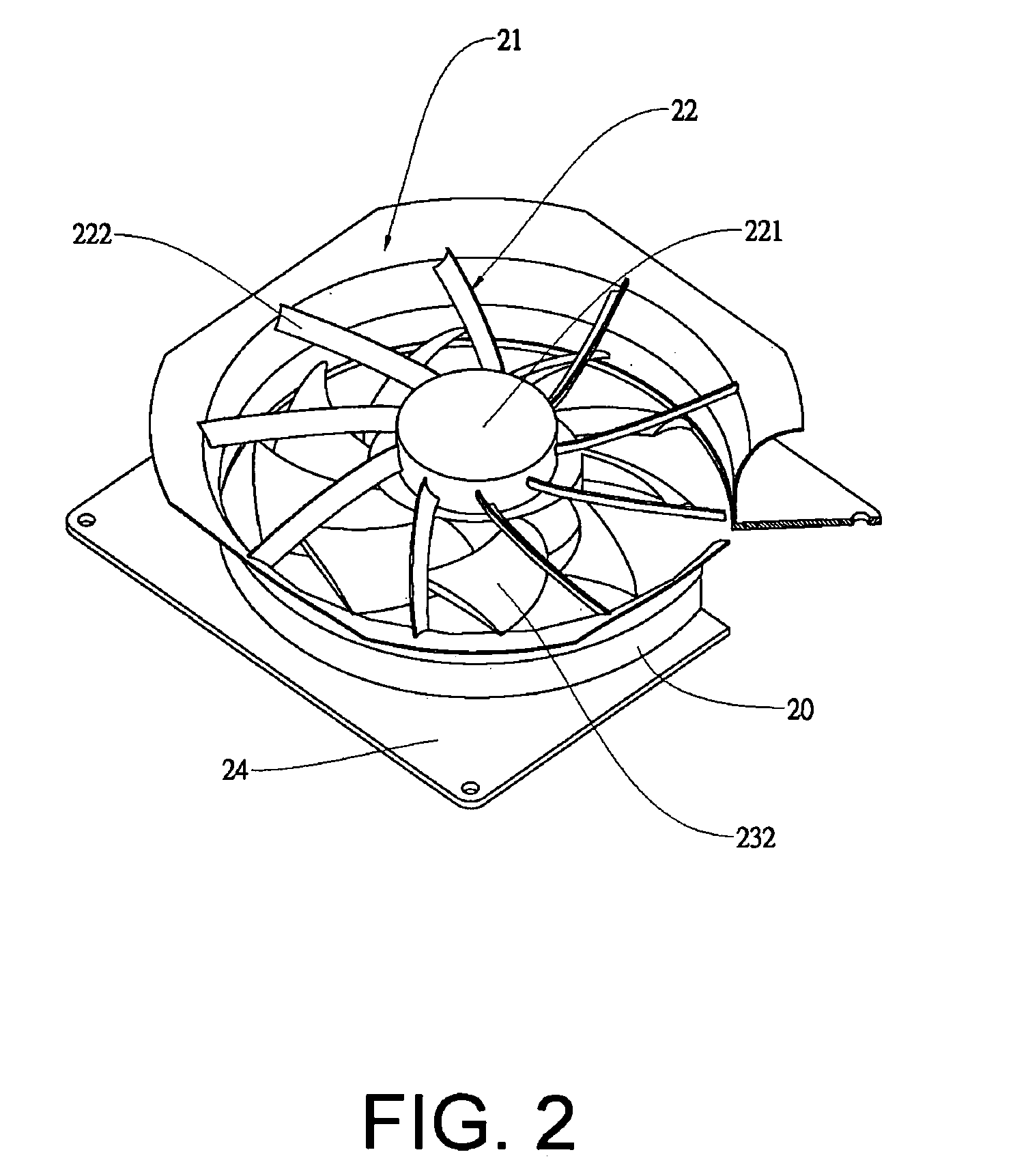

[0018]Referring to FIGS. 2 and 3, the structure of a heat sink according to an embodiment of the present invention comprises a ring 20, an air inlet 21, a securing portion 22 and a fan 23. The ring 20 is vertically positioned and comprises an air inlet side 201 and an air outlet side 202. The air inlet 21 vertically protrudes outwards along the ring 20 in a horizontal direction forming an arched side 211 with at least one arch structure. The arched side 211 may comprise a smooth shape, a trumpet shape or a stair-case shape. The ring 20 comprises a protruding portion 212 vertically protruding there-from. The dimension of the air inlet 21 is slightly larger than that of the air outlet side 202. Thus, the airflow area is significantly increased.

[0019]The securing portion 22 comprises a support chassis 221 and a plurality of blades 222. The support chassis 221 is positioned on the air inlet side 201 of the ring 20, and the blades 222 are radially positioned connecting the supporting cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com