Novel high-reliability waveguide ring isolation assembly structure

A reliable technology for isolating components, applied in waveguide-type devices, electrical components, circuits, etc., can solve the problems of poor thermal conductivity and low connection strength, avoid affecting performance parameters, improve reliability, and achieve the effect of seamless connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

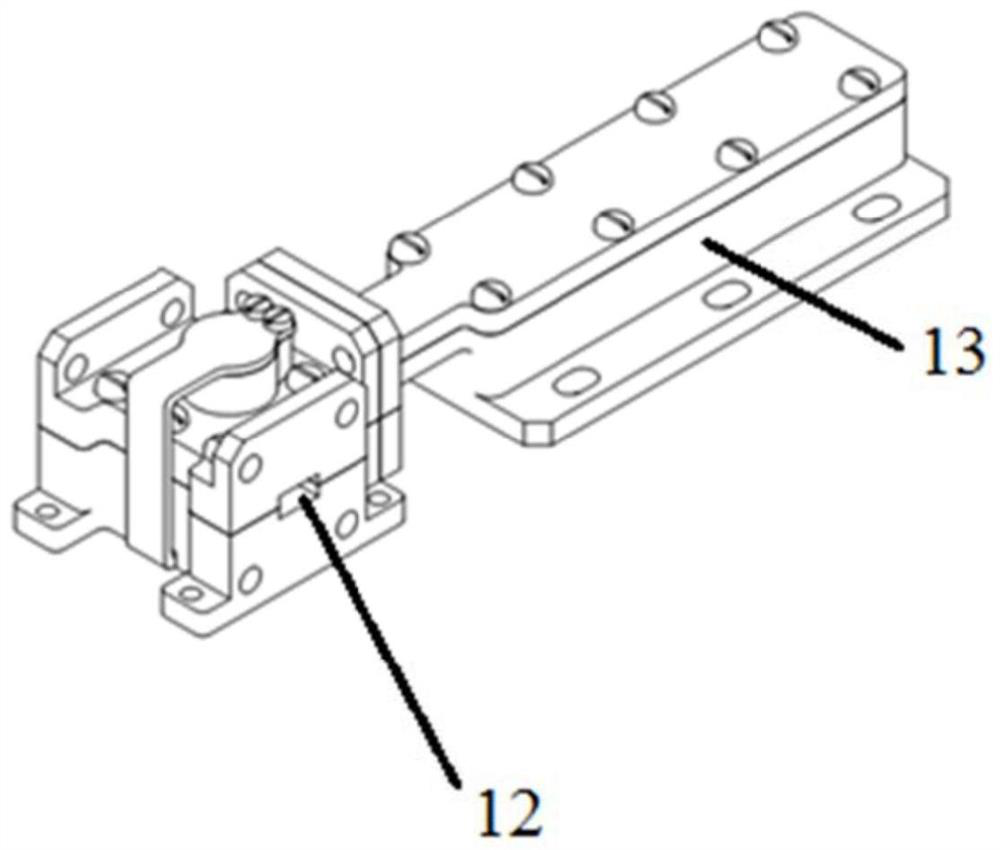

Embodiment 1

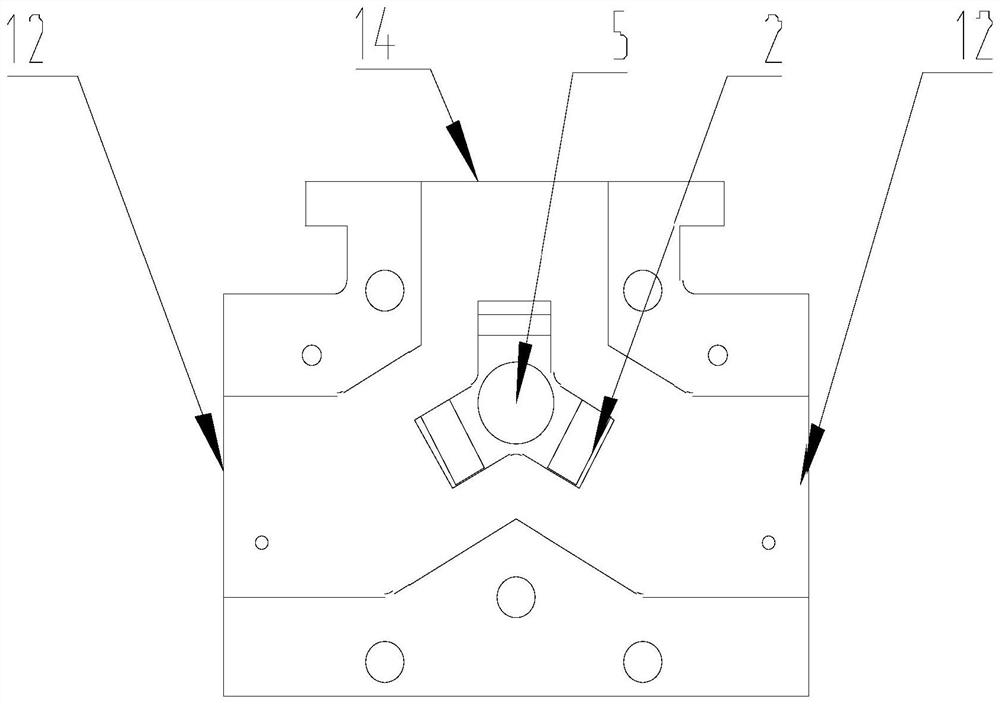

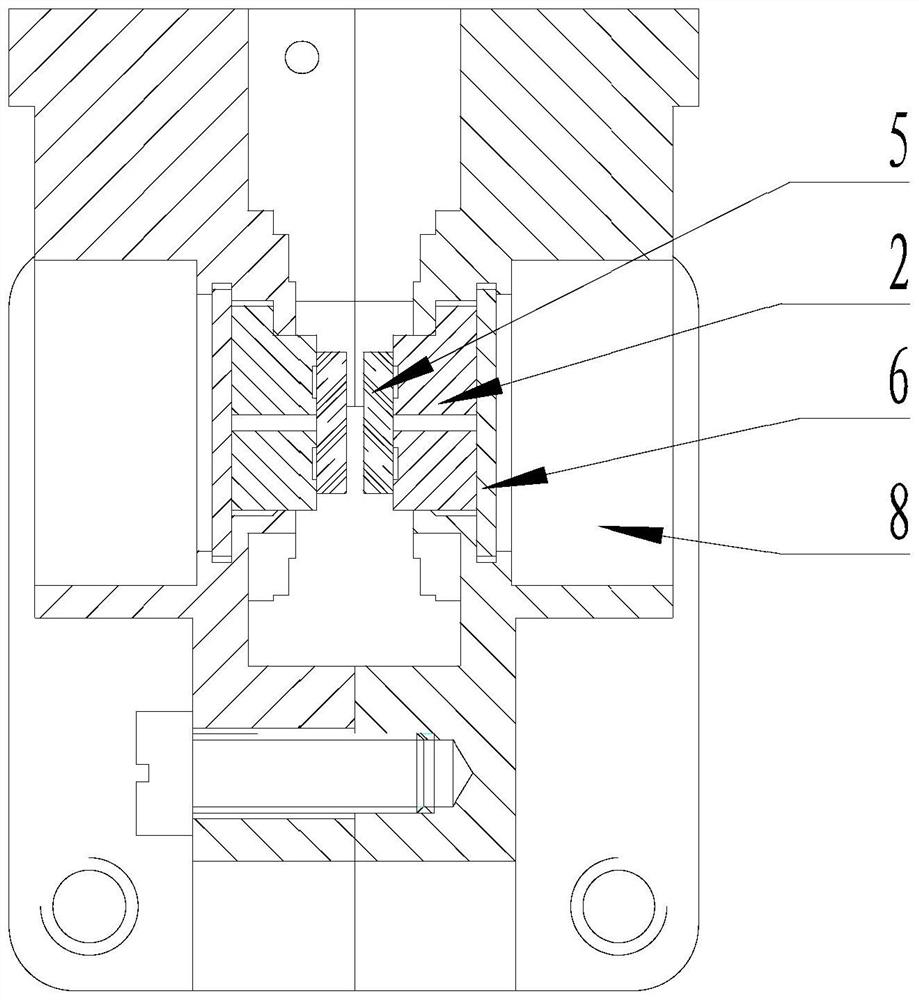

[0072] In the present invention, the ferrite 5 and the ferrite base 4 are welded by metal welding, and then the Y-shaped structure in the ferrite base 4 is placed in the welding groove 1, and the circlip 6 is used to place the circlip groove 3 The ferrite base 4 is fixed inside, and at the same time, in order to take into account the firmness of the welding and the cleanliness of the cavity 9, an avoidance groove 10 is designed.

[0073] The welding contact surface between the ferrite 5 material and the ferrite base 4 should be flat and uniform, and there should be no gaps or part warping, otherwise the microwave parameters of the ring isolation component will deteriorate. Since excess solder will affect the normal transmission of electromagnetic waves, the entire isolator needs to strictly control excess solder.

[0074] like figure 2 , as shown in 4, the ferrite 5 is in the shape of a cylinder, and there is a baked silver layer 7 on the welding surface. In order to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com