Evaporator fan with shroud assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

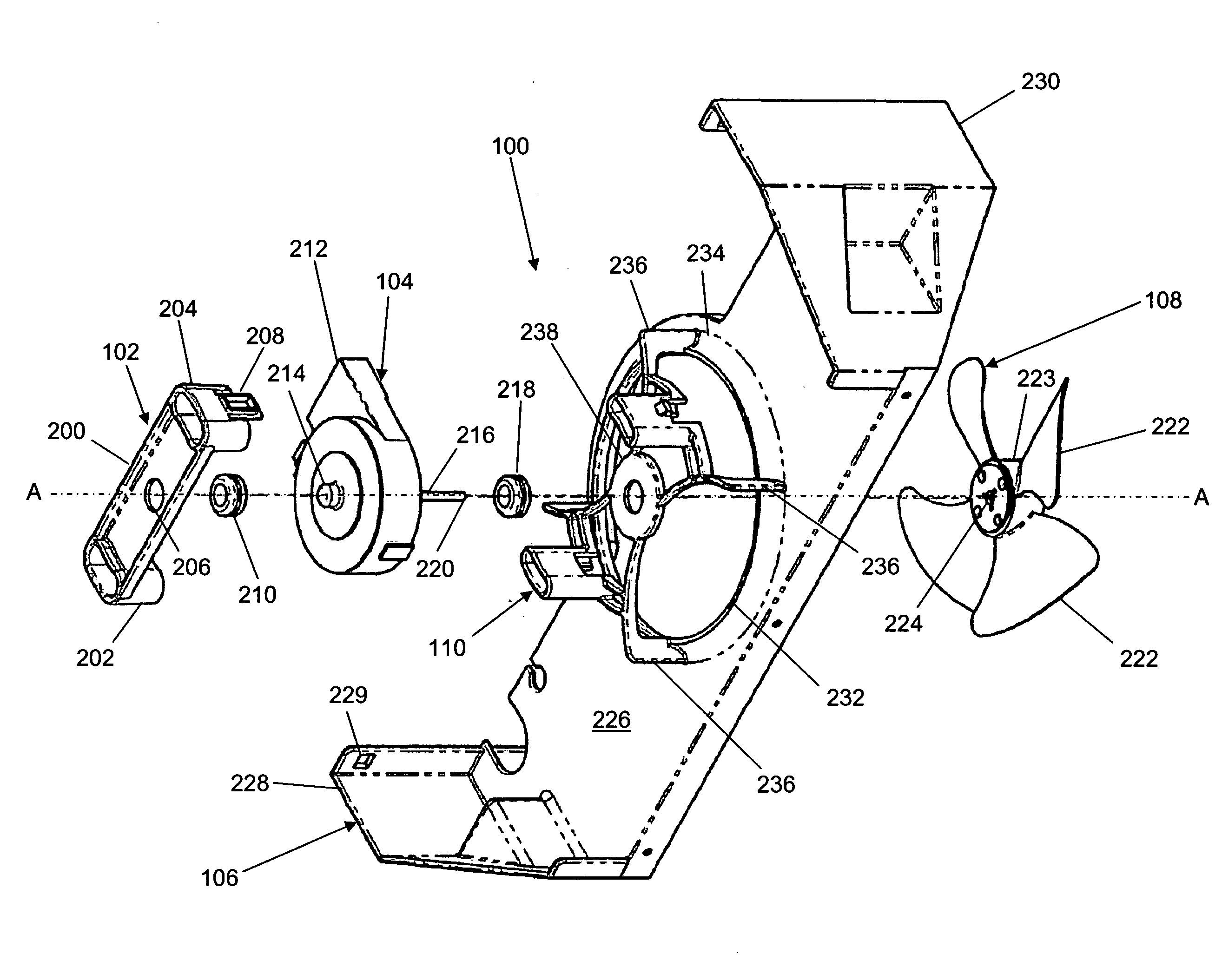

[0014]With reference to FIG. 1, a fan assembly 100 includes a mounting bracket 102, an actuator housing 104, a fan mounting frame 106, a fan 108, and a shroud 110. Fan assembly 100 may be mounted for use within a variety of devices. In an exemplary embodiment, fan assembly 100 is mounted adjacent a heat exchanger to circulate heated / cooled air. For example, fan assembly 100 may be mounted adjacent an evaporator in a refrigerator for circulation of cooled air. As used in this disclosure, the term “mount” includes join, unite, connect, associate, insert, hang, hold, affix, attach, fasten, bind, paste, secure, bolt, screw, rivet, solder, weld, and other like terms.

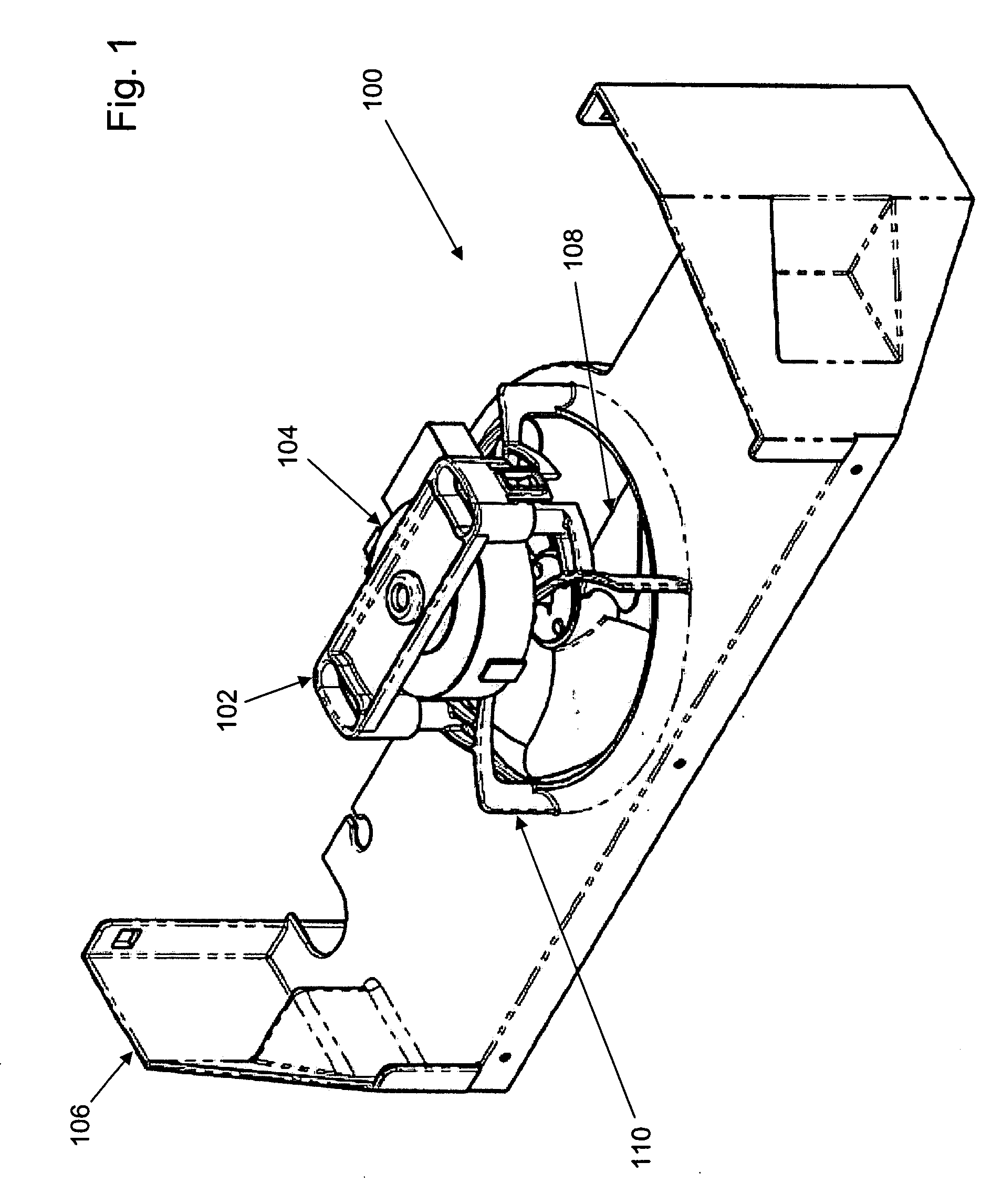

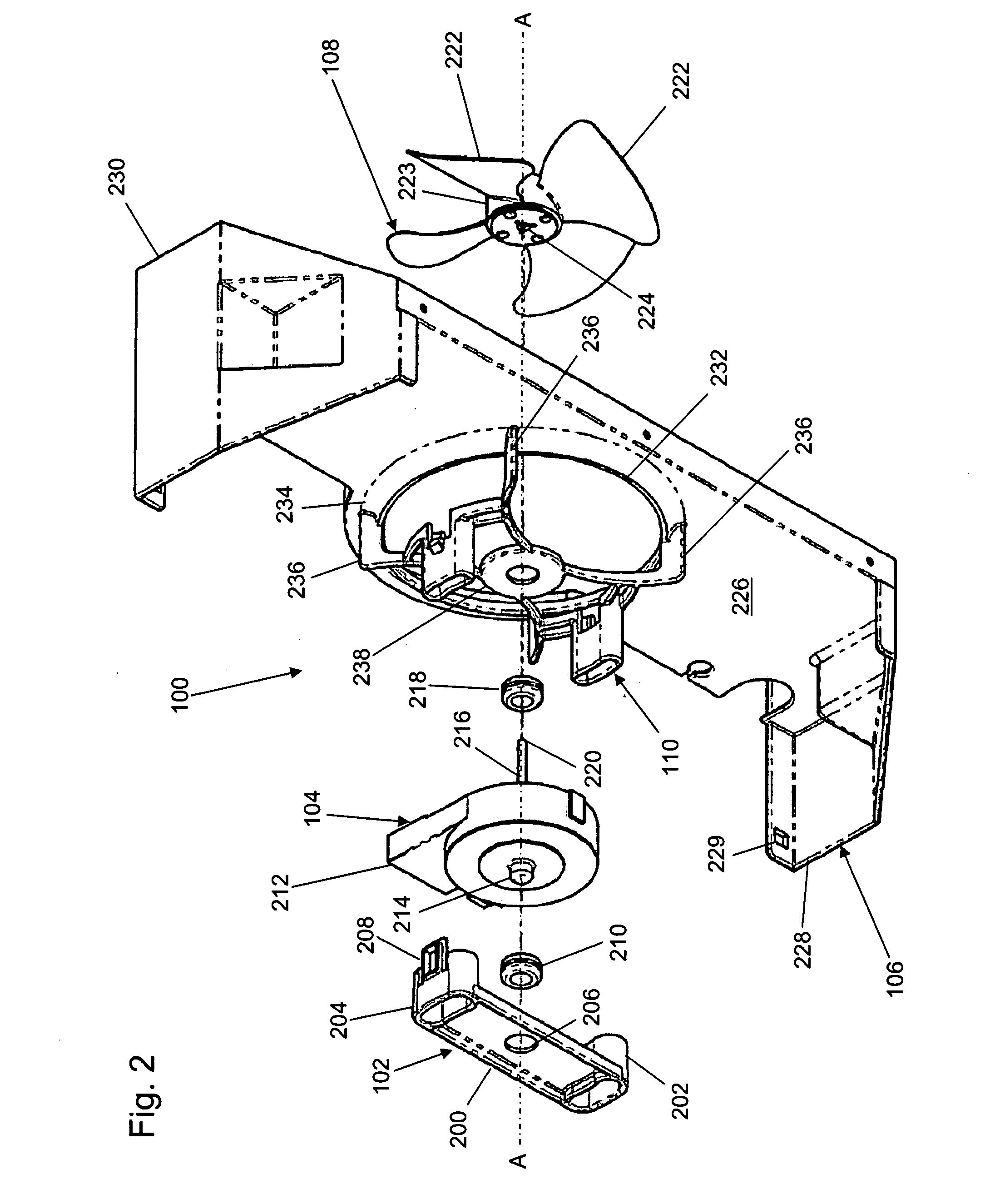

[0015]With reference to FIG. 2, an exploded view of fan assembly 100 is provided. Mounting bracket 102 may include a body 200, a first mounting arm 202, and a second mounting arm 204. First mounting arm 202 extends from a first end of body 200. Second mounting arm 204 extends from a second end of body 200 opposite the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com