Machine for removing the sharp edge in plates in general and in particular in glass plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

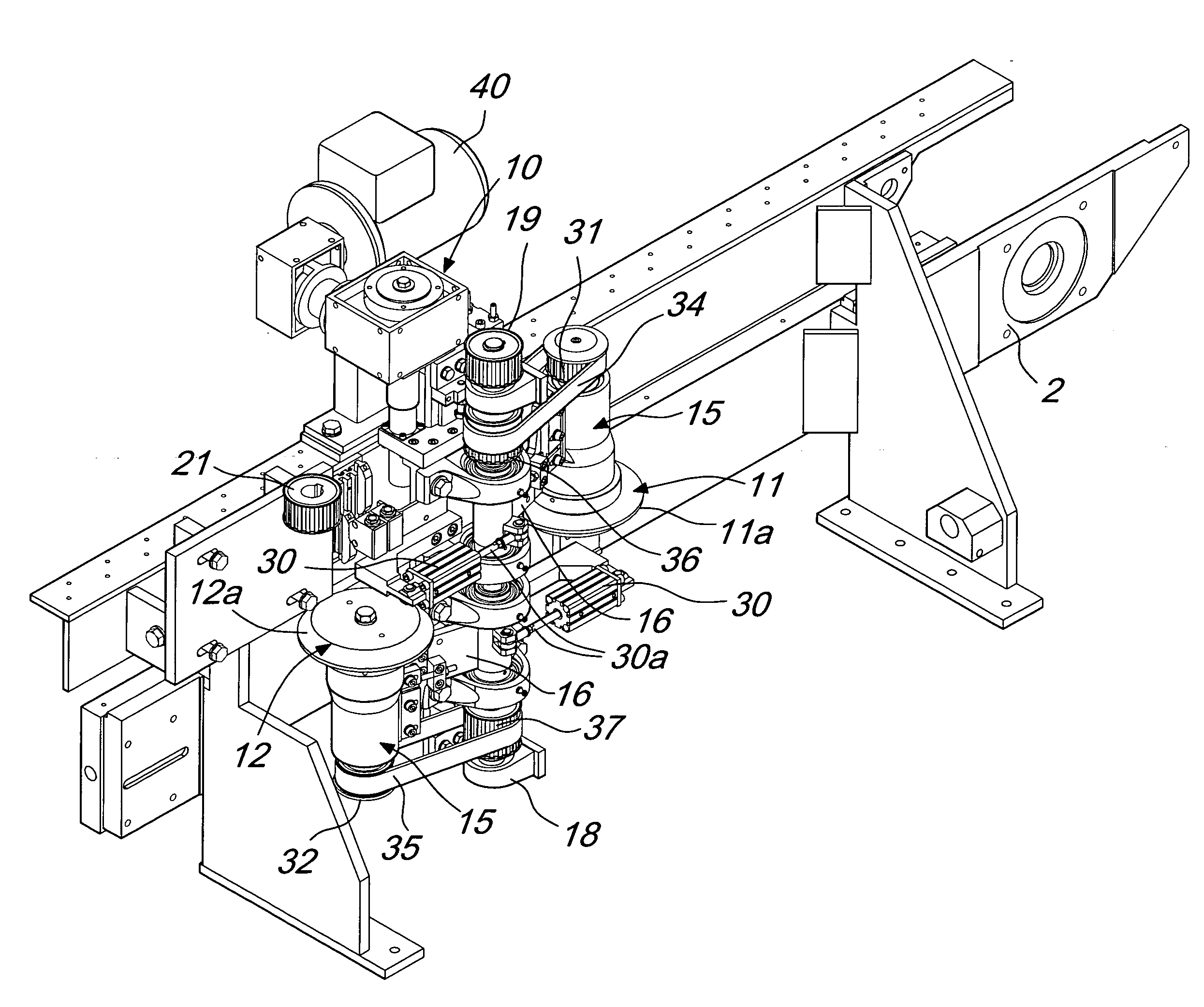

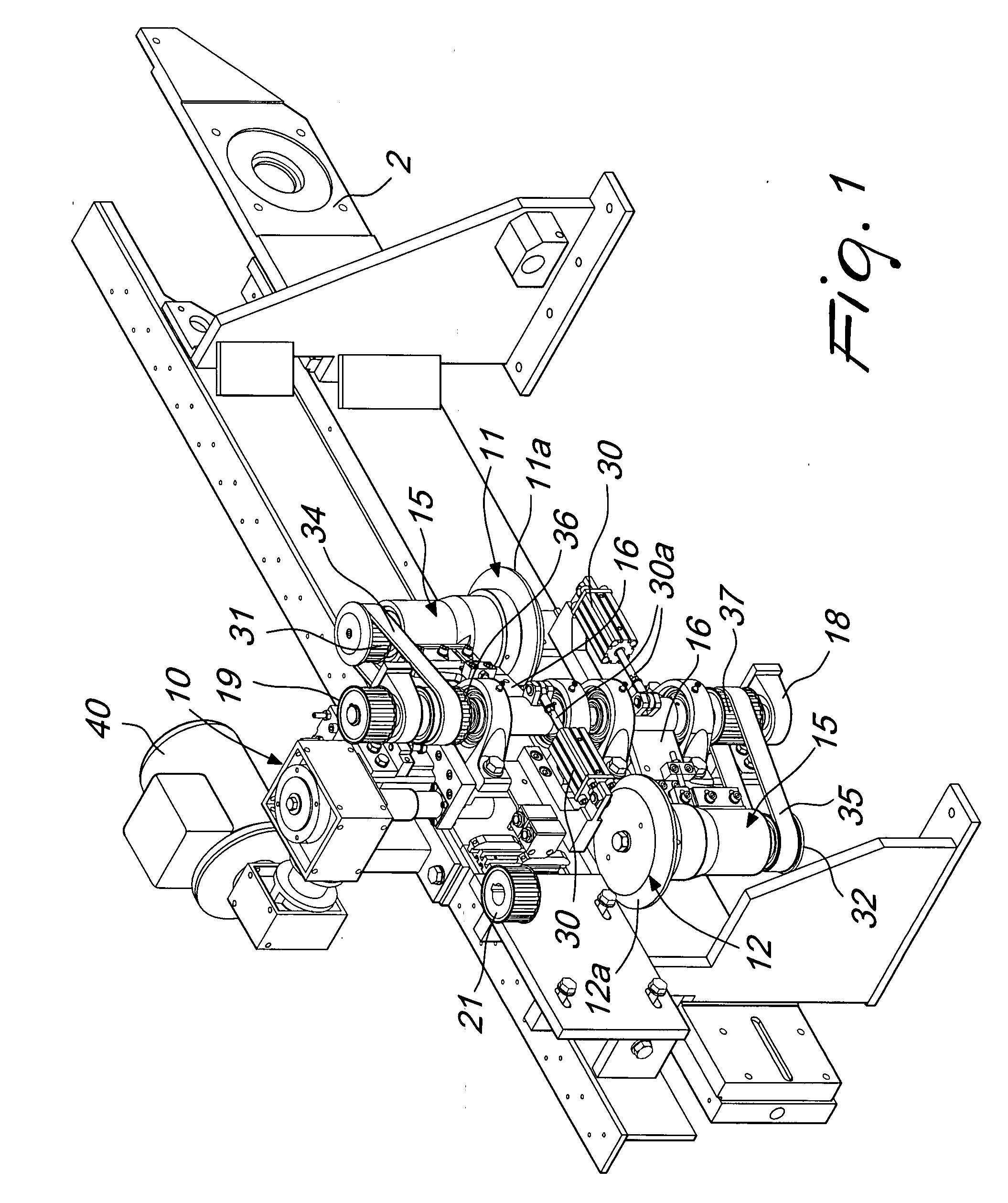

[0028]With reference to the figures, the machine for removing the sharp edge in plates in general and in glass plates in particular, generally designated by the reference numeral 1, comprises a frame 2 for the support and advancement of a plate 3 which is rested for example on a belt 4 which unwinds continuously.

[0029]At least one and preferably a plurality of arrissing stations, generally designated by the reference numeral 10, are typically provided at the edges of the plate.

[0030]Arrissing stations are usually provided on both of the advancement sides of the plate, which has a rectangular shape, and moreover the line provides for two machines with an interposed 90° transfer system, so that all the four edges of the plate are machined.

[0031]The drawing illustrates a single arrissing station, but of course, as mentioned earlier, the stations are typically four in number.

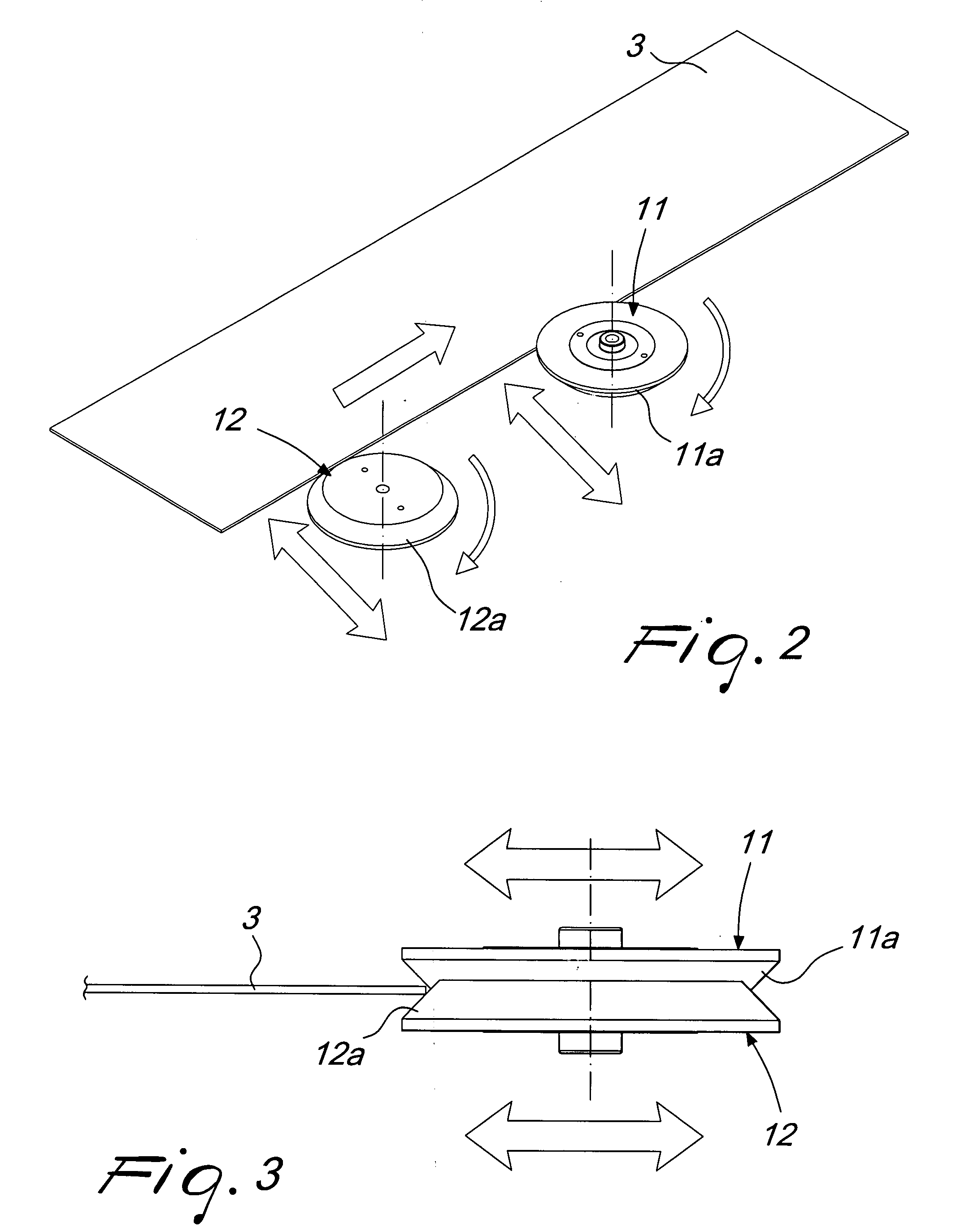

[0032]Each arrissing station 10 comprises an upper tangential grinding wheel 11 and a lower tangential grinding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com